Rhenium sulfide/nitrogen-doped biomass-based carbon fiber composite material with double-defect structure and preparation method

A technology based on carbon fiber and defect structure, applied in the direction of carbon fiber, structural parts, fiber processing, etc., can solve the problems of electrochemical capacity decay, side reaction, irreversible change of layered structure, etc., to achieve good electrical conductivity, stable physical and chemical properties, The effect of increasing the active surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

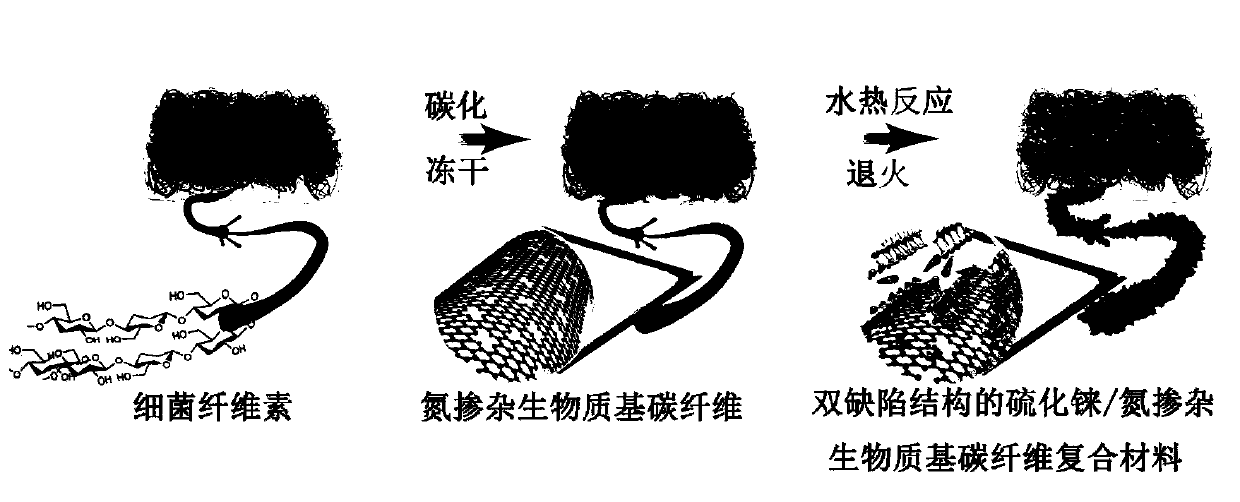

[0030] Such as figure 1 As shown, this embodiment provides a rhenium sulfide / nitrogen-doped biomass-based carbon fiber composite material with a double defect structure. The specific preparation steps are as follows:

[0031] Dissolve ammonium perrhenate, thiourea, and hydroxylamine hydrochloride in deionized water at a molar ratio of 1:2.2:3, and ultrasonically treat for 10 minutes to make it uniformly dispersed to obtain a mixed solution; then add nitrogen-doped biomass-based carbon fiber In this solution, and ultrasonic for 1h; transfer to a hydrothermal kettle for heating for hydrothermal reaction, the reaction temperature is 200 ℃, time is 24h; after the reaction is finished, cool to room temperature, wash the product with a mixed solution of ethanol and water, and Drying at 80℃ for 12h; finally, the product obtained in Ar / H 2 Annealed at 450°C for 2h in an atmosphere to obtain a rhenium sulfide / nitrogen-doped biomass-based carbon fiber composite material with a double defect...

Embodiment 2

[0033] Such as figure 1 As shown, this embodiment provides a rhenium sulfide / nitrogen-doped biomass-based carbon fiber composite material with a double defect structure. The specific preparation steps are as follows:

[0034] Dissolve ammonium perrhenate, thiourea, and hydroxylamine hydrochloride in deionized water at a molar ratio of 1:2.2:2, and ultrasonically treat for 10 minutes to make it evenly dispersed to obtain a mixed solution; then add nitrogen-doped biomass-based carbon fiber In this solution, and ultrasonic for 1h; transfer to a hydrothermal kettle for heating for hydrothermal reaction, the reaction temperature is 200 ℃, time is 24h; after the reaction is finished, cool to room temperature, wash the product with a mixed solution of ethanol and water, and Drying at 80℃ for 12h; finally, the product obtained in Ar / H 2 Annealed at 450°C for 2h in an atmosphere to obtain a rhenium sulfide / nitrogen-doped biomass-based carbon fiber composite material with a double defect st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com