Regeneration method of lithium iron phosphate in retired lithium battery

A lithium iron phosphate and lithium iron phosphate battery technology, which is applied in secondary batteries, battery electrodes, battery recycling, etc., can solve the problems of potential safety hazards, poor performance of lithium batteries, poor conductivity and cycle performance, and achieve excellent cycle performance , Youke capacity, and the effect of environmental protection in the regeneration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

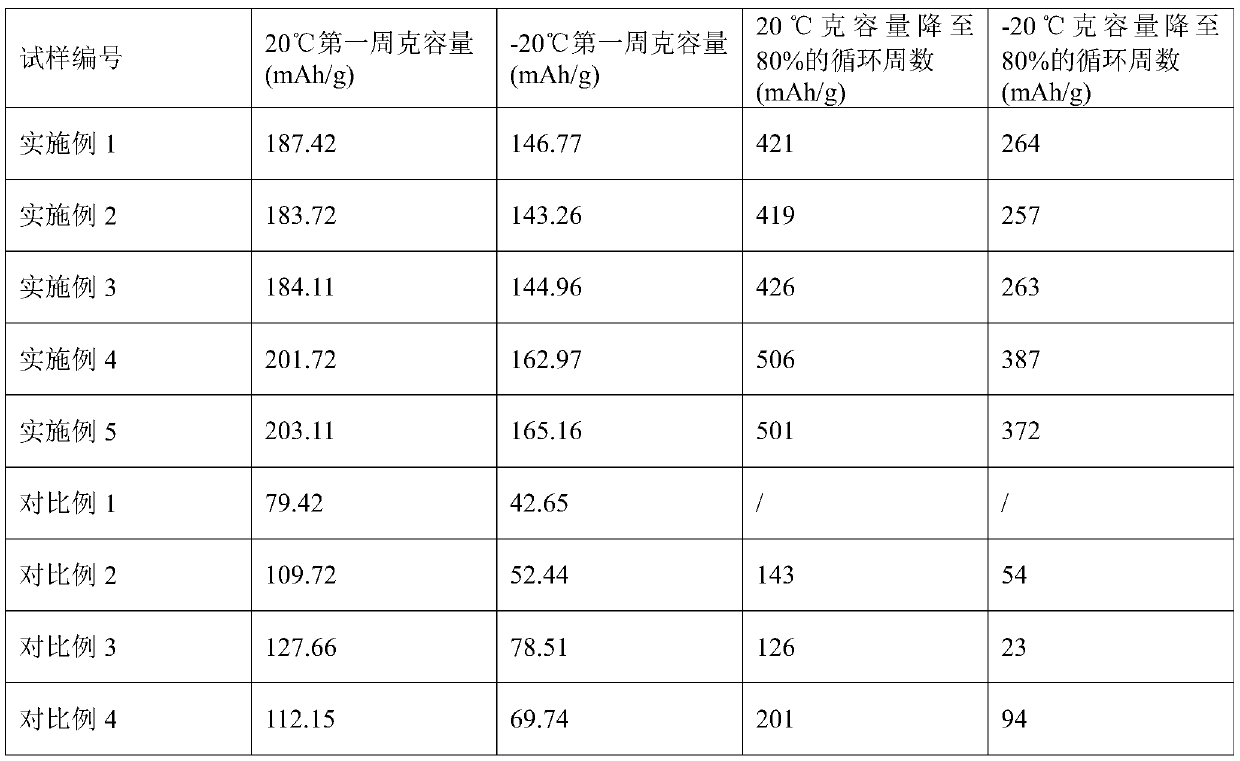

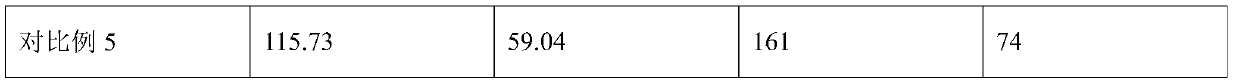

Examples

Embodiment 1

[0049] A method for regenerating lithium iron phosphate in a decommissioned lithium battery, said method comprising the following steps:

[0050] Disassemble the discarded lithium iron phosphate battery after complete discharge, and dismantle it in a glove box to separate the positive electrode material, place the positive electrode material in absolute ethanol for ultrasonic cleaning for 15 minutes, and centrifuge to remove a small amount of current collector residual components , followed by drying at 60°C for 2h, crushing and grinding to a particle size of ≤1mm to obtain a semi-finished product of lithium iron phosphate, 1000g of semi-finished product of lithium iron phosphate and 65g of 1500 mesh aluminum powder and 35g of B-mMPCFs fiber (2.66wt% boron doped mesophase pitch-based graphite fibers, the fiber length is 0.4-0.5 μm), and then placed in 2000g of absolute ethanol for wet ball milling for 1 hour to obtain a mixed slurry, which was pre-dried at 60°C until the water ...

Embodiment 2

[0052] A method for regenerating lithium iron phosphate in a decommissioned lithium battery, said method comprising the following steps:

[0053]Disassemble the discarded lithium iron phosphate battery after complete discharge, and dismantle it in a glove box to separate the positive electrode material, place the positive electrode material in absolute ethanol for ultrasonic cleaning for 15 minutes, and centrifuge to remove a small amount of current collector residual components , followed by drying at 60°C for 2 hours, crushing and grinding to a particle size ≤ 1mm to obtain a semi-finished product of lithium iron phosphate, 1000g of semi-finished product of lithium iron phosphate and 55g of 1500 mesh aluminum powder and 45g of B-mMPCFs fiber (2.66wt% boron doped mesophase pitch-based graphite fibers, the fiber length is 0.4-0.5 μm), and then placed in 2000g of absolute ethanol for wet ball milling for 1 hour to obtain a mixed slurry, which was pre-dried at 60°C until the wate...

Embodiment 3

[0055] A method for regenerating lithium iron phosphate in a decommissioned lithium battery, said method comprising the following steps:

[0056] Disassemble the discarded lithium iron phosphate battery after complete discharge, and dismantle it in a glove box to separate the positive electrode material, place the positive electrode material in absolute ethanol for ultrasonic cleaning for 15 minutes, and centrifuge to remove a small amount of current collector residual components , followed by drying at 60°C for 2h, crushing and grinding to a particle size of ≤1mm to obtain a semi-finished product of lithium iron phosphate, 1000g of semi-finished product of lithium iron phosphate and 30g of 1500 mesh aluminum powder and 20g of B-mMPCFs fiber (2.66wt% boron doped mesophase Pitch-based graphite fibers, the fiber length is 0.4-0.5 μm) mixed, and then placed in 2000g of absolute ethanol for wet ball milling for 1 hour to obtain a mixed slurry, which was pre-dried at 80°C until the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com