A clinically shapeable magnesium silicate/polyamino acid composite material and its use in preparing bone repair materials

A polyamino acid and composite material technology, applied in the direction of magnesium silicate, silicate, prosthesis, etc., can solve the problems of poor osteogenesis, inability to effectively promote osteoblast proliferation, and lack of biological activity, so as to promote bone marrow Proliferation of mesenchymal stem cells, convenient clinical shaping, and good biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

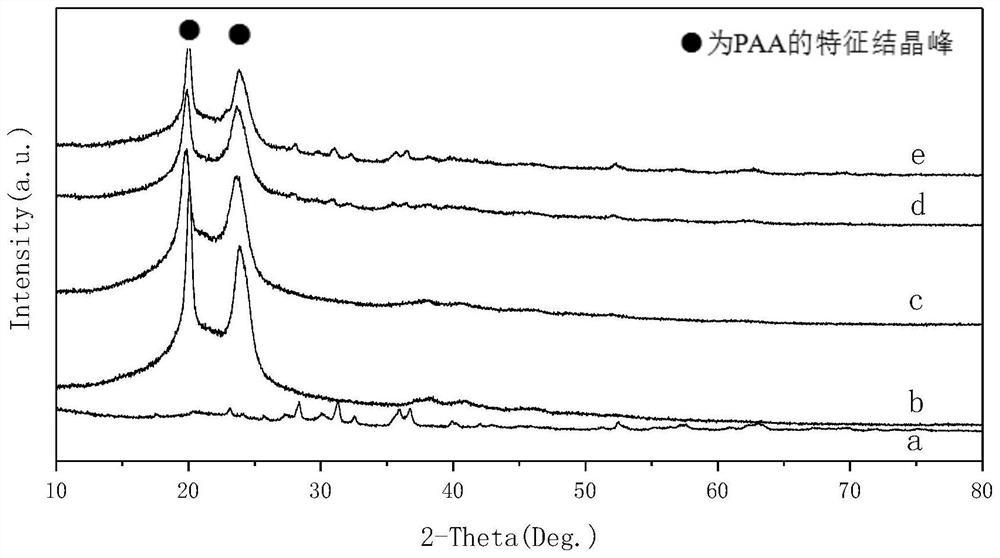

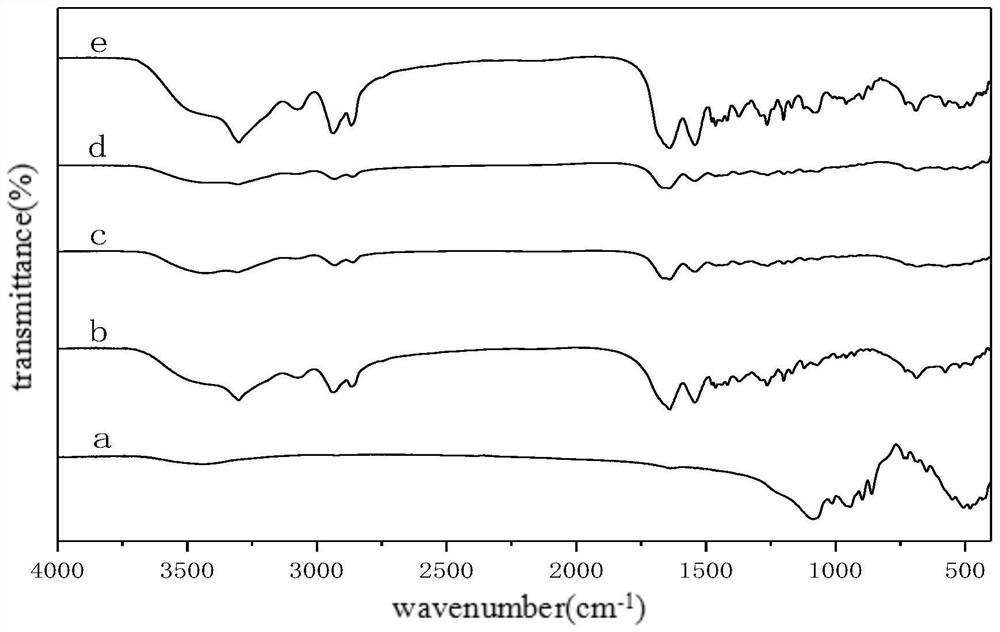

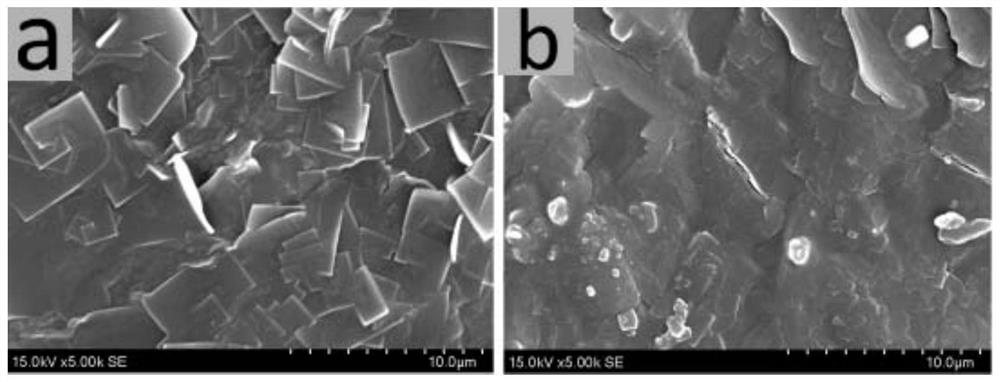

[0051] The preparation of embodiment 1 amino acid copolymer

[0052] Weigh 95g of 6-aminocaproic acid, 24g of 4-aminobutyric acid, 5g of proline, and 3g of lysine, put them into a 250ml three-neck flask, add 60mL of deionized water at the same time, and add 0.1mL of catalyst phosphoric acid, oil Heat the bath and keep stirring to 160°C for 1 hour of dehydration, raise the temperature to 200°C for 1 hour, and continue to raise the temperature to 210°C for 3 hours. In order to avoid oxidation, nitrogen protection was used throughout the experiment, and the resulting product was amino acid copolymer, named PAA.

Embodiment 2

[0053] The preparation of embodiment 2 amino acid copolymers

[0054] Weigh 95g of 6-aminocaproic acid, 24g of 4-aminobutyric acid, 5g of proline, and 3g of lysine, put them into a 250ml three-neck flask, add 60mL of deionized water at the same time, and add 0.1mL of catalyst phosphoric acid, oil Heat the bath and keep stirring to dehydrate at 160°C for 1 hour, raise the temperature to 200°C for 1 hour, and continue to raise the temperature to 220°C for 4 hours. In order to avoid oxidation, nitrogen protection was used throughout the experiment, and the resulting product was amino acid copolymer.

Embodiment 3

[0055] Embodiment 3 Preparation of amino acid copolymer

[0056] Weigh 94g of 6-aminocaproic acid, 24g of 4-aminobutyric acid, 5g of proline, 3g of lysine, and 1.5g of glutamic acid, put them into a 250ml three-necked flask, add 60mL of deionized water at the same time, and add Catalyst Phosphoric acid 0.1mL, heated in an oil bath and continued to stir to dehydrate at 160°C for 1h, raise the temperature to 200°C for 1h, and continue to raise the temperature to 220°C for 3h. In order to avoid oxidation, nitrogen protection was used throughout the experiment, and the resulting product was amino acid copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com