A treatment method for ultra-low discharge of emulsion wastewater in manufacturing industry

A treatment method and technology for emulsification, applied in the fields of environmental protection and wastewater treatment, can solve the problems of unsuitable emulsification of wastewater, poor effect, waste of resources, etc., and achieve improved biodegradability, good demulsification effect, and improved effluent quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Emulsion wastewater after sand removal, water quality: pH 8.0, water temperature 20°C, COD concentration 50,000 mg / L, ammonia nitrogen concentration 260 mg / L, total nitrogen concentration 1100 mg / L, total phosphorus concentration 280 mg / L .

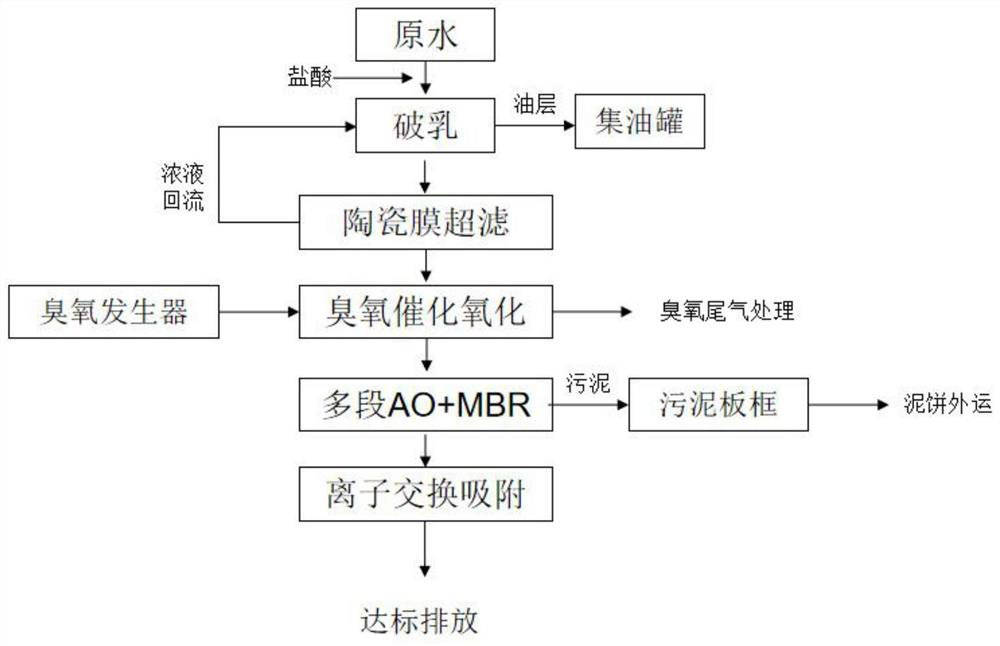

[0040] S1. Demulsification: Add 12mol / L hydrochloric acid to 1 ton of emulsion wastewater after desanding and stir until pH<5, then naturally settle for 30 minutes to separate oil and water, collect waste oil from the upper layer for recycling, and collect wastewater from the lower layer for further processing;

[0041] S2. Ultrafiltration: Under 0.2Mpa pressure, the wastewater in the lower layer is ultrafiltered through a cerium oxide-modified flat ceramic membrane. The concentrated liquid is returned to S1 for demulsification, and the ultrafiltered water is added with a regulator to adjust the pH value to 7;

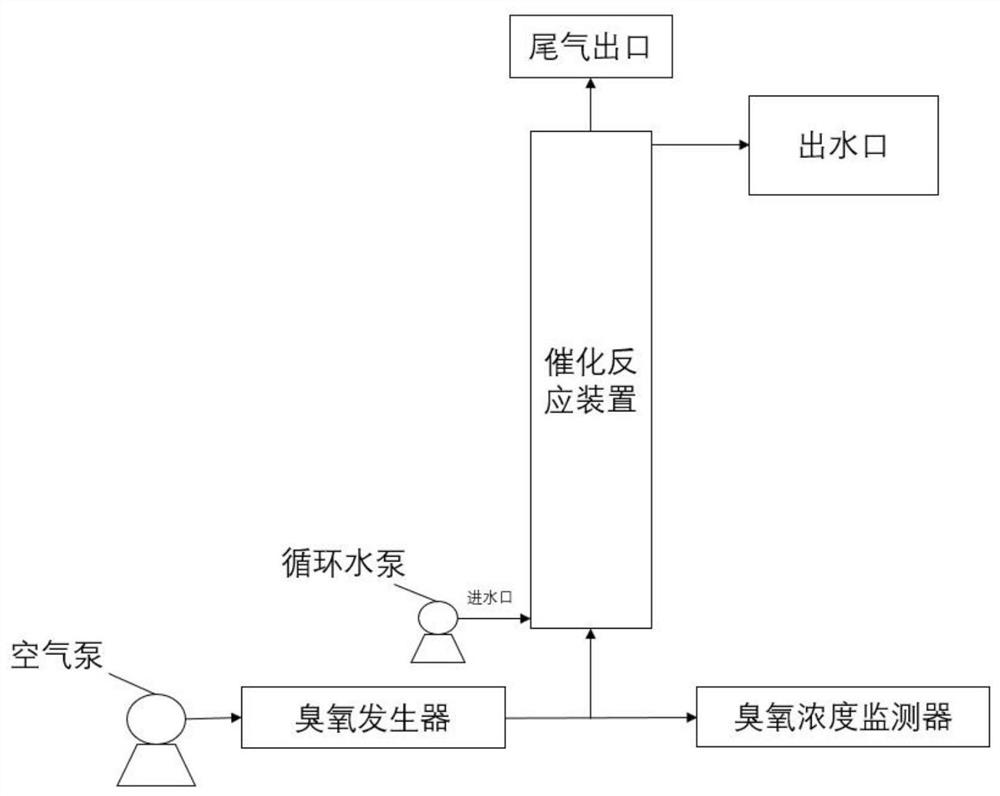

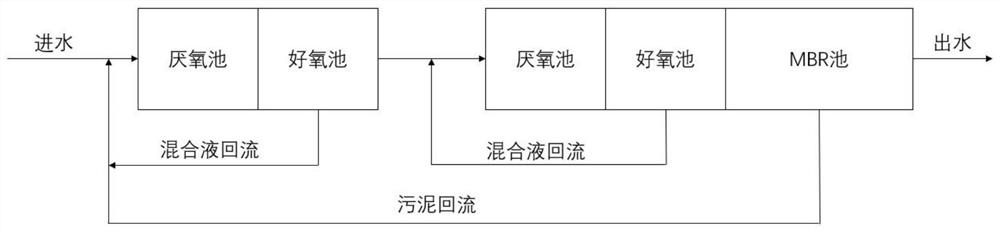

[0042] S3. Ozone catalytic oxidation: introduce the adjusted ultrafiltration water into the ozone catalytic oxidation un...

Embodiment 2

[0047] The water quality of the emulsion wastewater after sand removal: pH is 8.2, water temperature is 20°C, COD concentration is 180,000 mg / L, ammonia nitrogen concentration is 308 mg / L, total nitrogen concentration is 902 mg / L, and total phosphorus concentration is 840 mg / L .

[0048] S1. Demulsification: After desanding 1 ton of emulsion wastewater, add 12mol / L hydrochloric acid and stir until pH<3, settle naturally for 15 minutes to separate oil and water, collect waste oil from the upper layer for recycling, and collect wastewater from the lower layer for further processing;

[0049] S2. Ultrafiltration: Under 0.3Mpa pressure, the wastewater in the lower layer is ultrafiltered through a cerium oxide-modified flat ceramic membrane, the water output is 60-90%, the filtration flow rate is about 10-200LMH, the membrane pore size is about 0.05μm, and the ultrafiltration dope Return to S1 for demulsification, and add a regulator to the ultrafiltered water to adjust the pH valu...

Embodiment 3

[0055] Emulsion wastewater after desanding, water quality: pH is 9.0, water temperature is 22°C, COD concentration is 150,000 mg / L, ammonia nitrogen concentration is 380 mg / L, total nitrogen concentration is 1400 mg / L, and total phosphorus concentration is 620 mg / L .

[0056] S1. Demulsification: After desanding 1 ton of emulsion wastewater, add 12mol / L hydrochloric acid and stir until pH<3, settle naturally for 15 minutes to separate oil and water, collect waste oil from the upper layer for recycling, and collect wastewater from the lower layer for further processing;

[0057] S2. Ultrafiltration: Under 0.3Mpa pressure, the wastewater in the lower layer is treated by ultrafiltration through a flat ceramic membrane modified by cerium oxide. The water output is 60-90%, the filtration flow rate is about 10-200LMH, and the membrane pore The solution is returned to S1 for demulsification, and the ultrafiltered water is added with a regulator to adjust the pH value to 9;

[0058] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com