Method for inhibiting quantum dot surface defect state based on crystal face control

A technology of quantum dots and defect states, applied in the field of compound semiconductor nanomaterial preparation, can solve the problems of easy detachment of ligands on the surface of quantum dots, insufficient passivation of crystal planes, etc., and achieve the effects of improving optoelectronic performance, suppressing defect states, and effectively regulating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

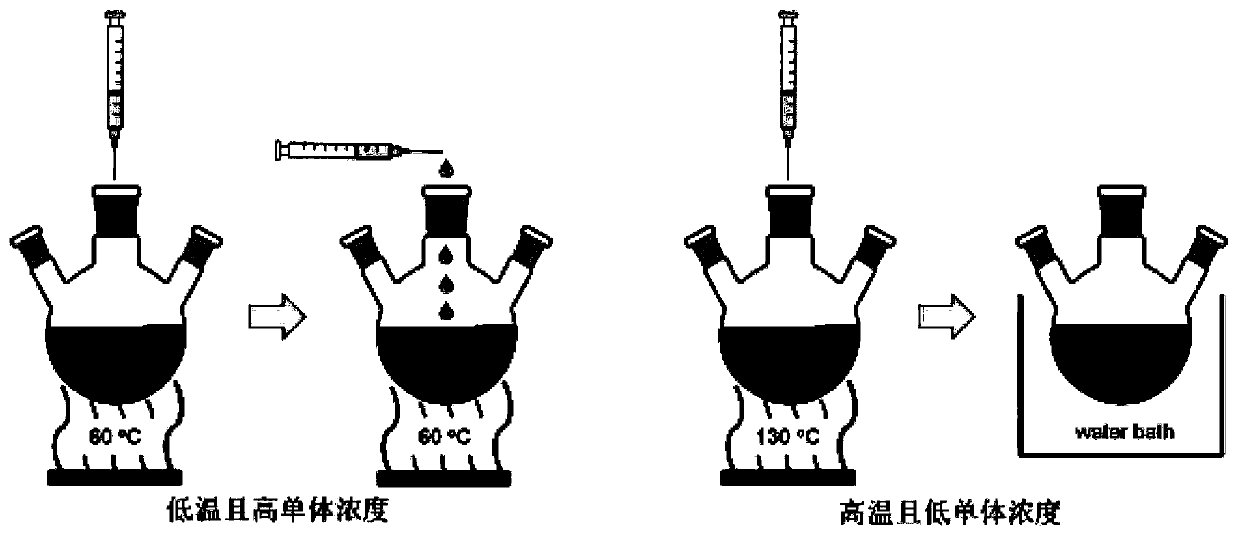

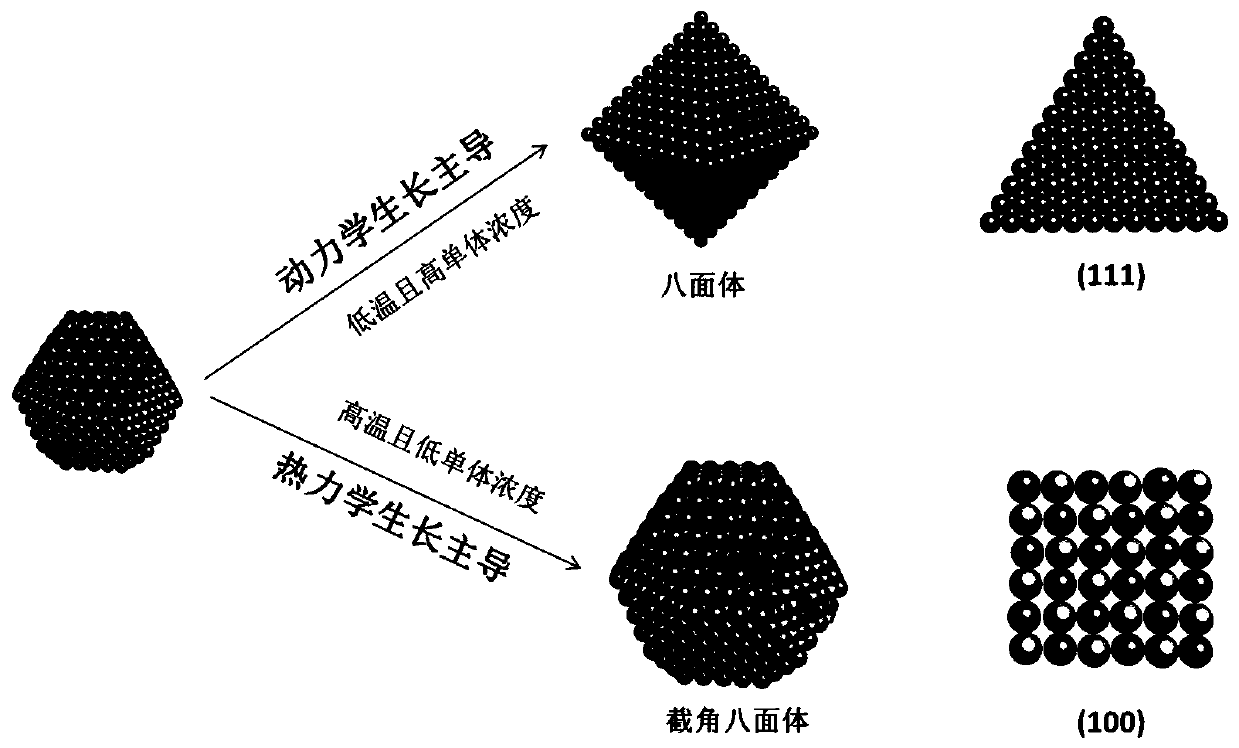

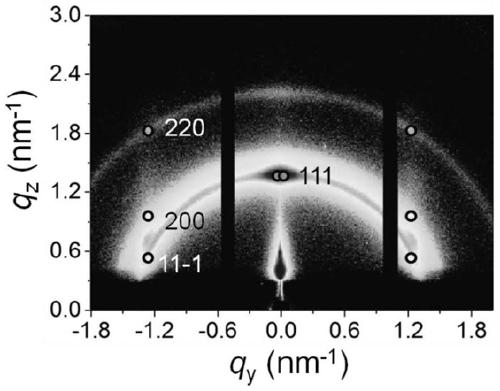

Method used

Image

Examples

Embodiment 1

[0044] (1) Weigh 8.82g of zinc stearate, 0.45g of thioacetamide, and 100ml of ODE (1-octadecene) in a two-necked reaction flask. After vacuumizing the mixture, heat it to 140°C and keep it for 50min;

[0045] (2) Cool the product in a water bath to 50°C, add 4ml of n-octylamine, add ethanol after the solution is clarified, centrifuge, and wash twice to obtain ZnS quantum dots whose first excitation peak is 256nm;

[0046] (3) The cleaned ZnS quantum dots are respectively configured into two solutions with a higher concentration of 0.6mol / L and a lower concentration of 0.2mol / L, and the solvents are ODE;

[0047] (4) Weigh 2.919g of lead chloride and 35ml of oleylamine in another two-necked reaction flask, and heat the mixture to 140°C for 30min after vacuumizing the mixture;

[0048] (5) Cool down to 60°C, quickly inject 5ml of ZnS quantum dot solution with a concentration of 0.6mol / L (the time of rapid injection should not exceed 1s, of course, the faster the better), and slo...

Embodiment 2

[0053] (1) The procedure for the preparation of ZnS quantum dots is the same as in Example 1. Weigh 3.336g of lead chloride and 40ml of oleylamine in one or two reaction bottles. After the mixture is evacuated, it is heated to 140°C and maintained for 30min;

[0054] (2) Cool down to 40°C, quickly inject 5ml of ZnS quantum dot solution with a concentration of 0.6mol / L, and slowly add ZnS quantum dot solution with a concentration of 0.2mol / L after 15s at a rate of about 0.04mmol / min, and start timing;

[0055] (3) Sampling is used to detect dimensional changes. At the 35th minute, the temperature is heated to 60°C, which can speed up the growth rate of quantum dots (of course, the temperature can be higher, and the maximum cannot exceed 120°C). Continue to detect dimensional changes through sampling, and inject at the 55th minute. Dilute with 60ml of n-hexane, inject 35ml of oleic acid as a ligand after the temperature drops to 40°C.

[0056] (4) adding a mixed solution of eth...

Embodiment 3

[0058] (1) The procedure for the preparation of ZnS quantum dots is the same as in Example 1. Weigh 2.502g of lead chloride and 30ml of oleylamine in one or two reaction flasks. After the mixture is evacuated, it is heated to 140°C and maintained for 30min;

[0059] (2) Cool down to 70°C, quickly inject 5ml of ZnS quantum dot solution with a concentration of 0.6mol / L, and slowly add ZnS quantum dot solution with a concentration of 0.2mol / L after 15s at a rate of about 0.04mmol / min;

[0060] (3) Sampling was used to detect the size change. After 28 minutes, water bath was injected into 40ml of n-hexane for dilution. After the temperature dropped to 40°C, 20ml of oleic acid was injected as a ligand.

[0061] (4) adding a mixed solution of ethanol and acetone for centrifugation, and removing the supernatant to obtain ~3nm PbS quantum dots prepared at low temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com