Lubricating oil composition

A technology for lubricating oil compositions and mixtures, applied in lubricating compositions, petroleum industry, base materials, etc., can solve the problems of low kinematic viscosity, unevenness, low density, etc., and achieve strong thermal stability, good solubility, good The effect of low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

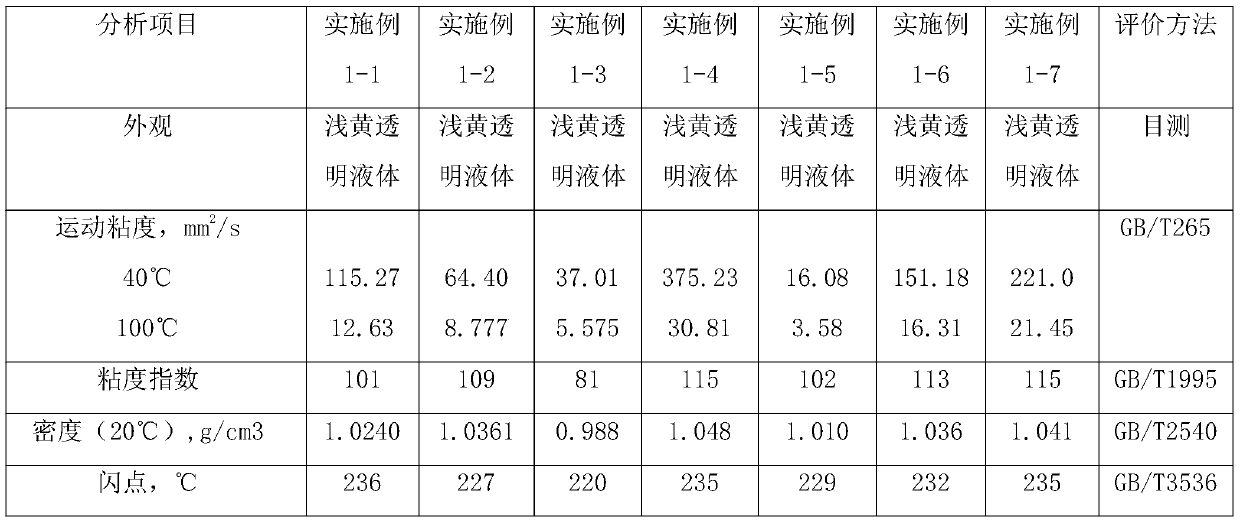

Examples

Embodiment 1-1

[0068] Example 1-1: 254 grams of dipentaerythritol, 213 grams of isobutyric acid, 213 grams of butyric acid, 2284 grams of isooctanoic acid, and 10 grams of catalyst p-toluenesulfonic acid were added to a 5-liter three-necked flask with a reflux device, and the vacuum pump was started to adjust the pressure. Raise the temperature, keep it at 220°C for 20 minutes, and remove the generated water. After the esterification is completed, use the ultimate vacuum to remove the distilled acid, half-ester, water and other mixtures, and further remove the residual acid by washing with alkali. water, filtered to obtain polyol esters. Add 2000 grams of polyol esters in the blending kettle, commercially available code is 4,4-methylene bis(2,6-di-tert-butylphenol) alkylphenol 4.3 grams, commercially available as tricresyl phosphate of T306 21 grams of esters, 7.5 grams of dodecyloxyalkylene, 1.5 grams of benzotriazindene with a commercially available code of T706, 0.125 grams of methyl sili...

Embodiment 1-2

[0069] Embodiment 1-2: Weigh 857 grams of pentaerythritol, 390 grams of isobutyric acid, 1109 grams of butyric acid, 258 grams of adipic acid, 1399 grams of isooctanoic acid, and 19 grams of catalyst sodium bisulfate into a 5-liter three-necked flask with a reflux device, Start the vacuum pump to adjust the pressure, gradually raise the temperature, keep it warm at 240°C for 20 minutes, and remove the generated water. After the esterification is completed, use the ultimate vacuum to remove the distilled acid, half-ester, water and other mixtures, and further remove the remaining residues by washing with alkaline water. acid, remove trace water by vacuum distillation, and obtain polyol ester by filtration. Add 2000 grams of polyol esters in the blending kettle, commercially available codes are 4.2 grams of alkylphenols T501, commercially available ZDDP 10.4 grams, 6.25 grams of dodecyloxyalkylenes, commercially available codes are benzotriazindene 2.1 grams of T706 gram, commer...

Embodiment 1-3

[0070] Example 1-3: Add 272 grams of pentaerythritol, 230 grams of isobutyric acid, 750 grams of isooctanoic acid, and 8 grams of catalyst sodium bisulfate into a 2-liter three-neck flask with a reflux device, start the vacuum pump to adjust the pressure, gradually increase the temperature, and keep warm at 230 ° C After 30 minutes, remove the generated water. After the esterification is completed, use extreme vacuum to remove the distilled acid, half-ester, water and other mixtures, and further remove the residual acid by washing with alkali, remove trace water by vacuum distillation, and obtain polyol by filtration. ester. Add 1000 grams of polyol esters in the blending kettle, the commercially available code is 2.2 grams of alkylphenols named RHY505, 10 grams of tricresyl phosphates commercially available as T306, commercially available 1,6 hexanediol diglycidyl 3.5 grams of ether, 0.5 grams of benzotriazindene whose commercially available code is T706, 0.005 grams of methy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com