Red date composite fruit wine formula and processing method

A compound fruit wine and processing method technology, which can be applied in the directions of pharmaceutical formulations, microbe-based methods, biochemical equipment and methods, etc., and can solve problems such as single taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

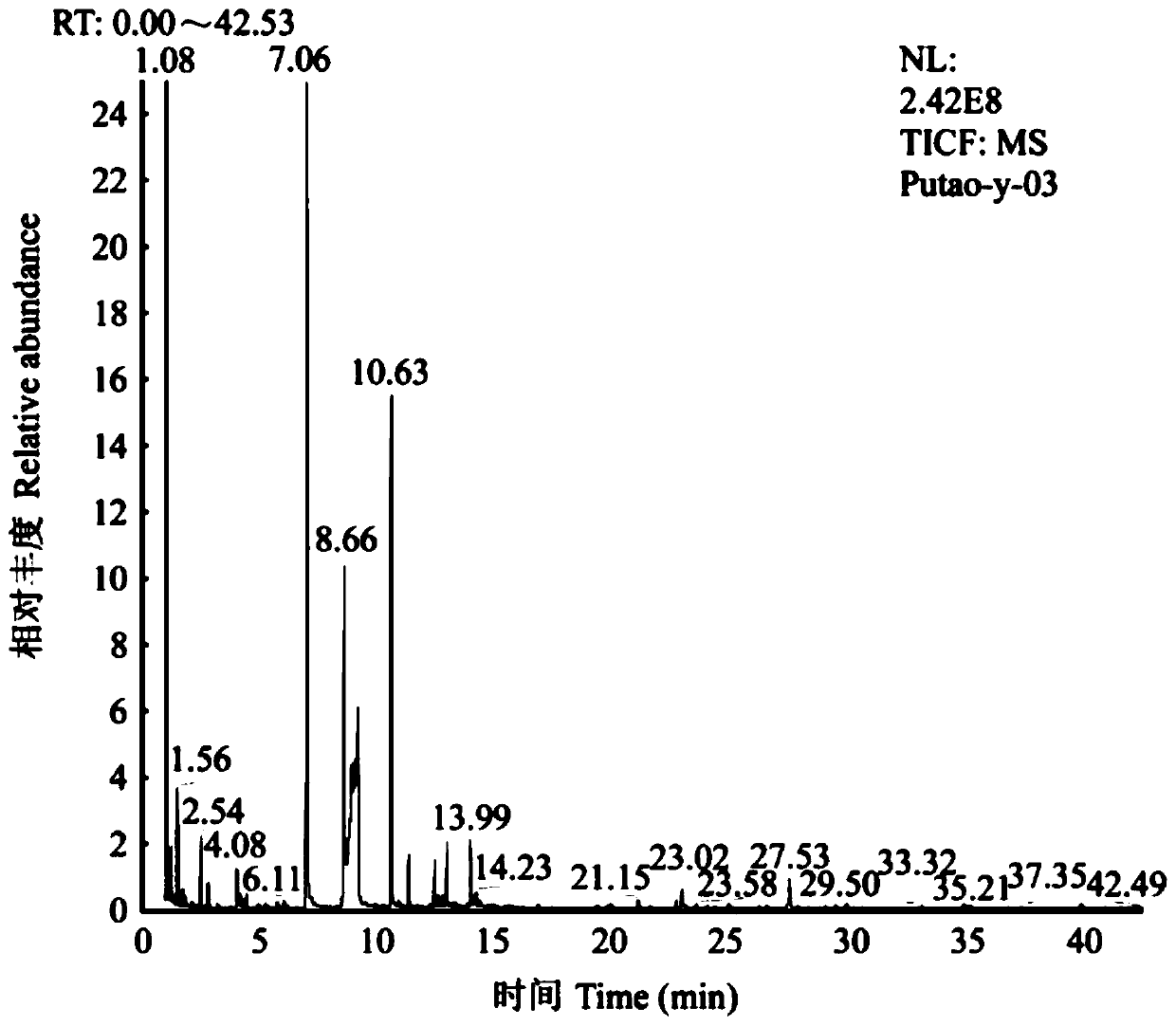

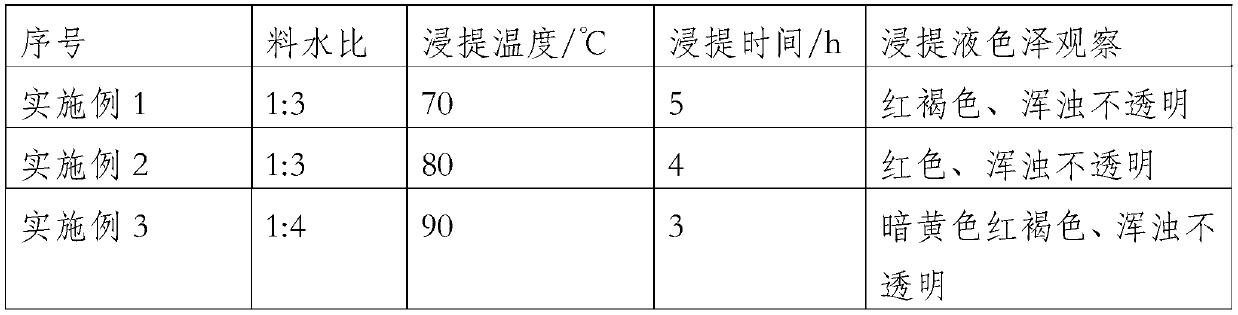

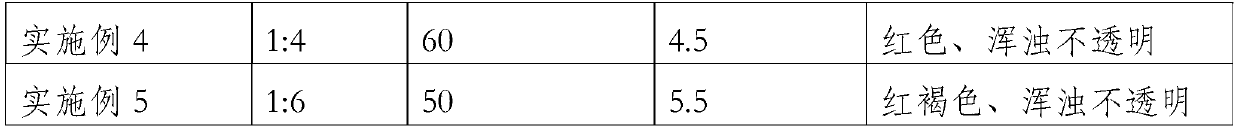

[0024] (1) Raw material pretreatment: remove the core of red dates and cut them into pieces, add red dates and water with a mass ratio of 1-5:1-5 for hot water extraction to obtain primary red date juice; add water to mix wolfberry, and the mass ratio is 1-5: 1-5, to obtain primary wolfberry juice; crush the grapes to obtain primary grape juice, add 1.5% glucoamylase, and stir for 2 hours; refer to Table 1 for the final material-liquid ratio and process of the above primary juice extraction.

[0025] (2) Fruit juice compounding: mix primary jujube juice, primary wolfberry juice and primary grape juice, and the mass ratio of red dates, wolfberry and grapes is 6-9:1-3:1-3 to obtain primary mixed juice;

[0026] (3) Component adjustment: Add calcium carbonate and sucrose to the primary mixed juice to adjust the pH to 0.01%, and adjust the sugar content to 20%, and add potassium metabisulfite to sterilize SO 2 The added amount is 30ppm, and the secondary mixed juice is obtained. ...

Embodiment 2

[0031] (1) Raw material pretreatment: remove the core of the red dates and cut them into pieces, add hot water extraction with a mass ratio of red dates and water of 3:2 to obtain primary red date juice; add water to mix wolfberry and make a pulp with a mass ratio of 3:1, Obtain primary wolfberry juice; crush the grapes to obtain primary grape juice, add 1% glucoamylase, and stir for 3 h;

[0032] (2) Fruit juice compounding: mix primary jujube juice, primary wolfberry juice and primary grape juice, the mass ratio of red dates, wolfberry, and grapes is 8:2:2, to obtain primary mixed juice;

[0033] (3) Component adjustment: Add calcium carbonate and sucrose to the primary mixed juice to adjust the pH to 0.03%, and adjust the sugar content to 24%, and add potassium metabisulfite to sterilize SO 2 The addition amount is 35ppm, and the secondary mixed juice is obtained.

[0034] (4) Fermentation: Add active dry yeast to 5% glucose solution, mix evenly, place in a constant temper...

Embodiment 3

[0038] (1) Raw material pretreatment: remove the core of red dates and cut them into pieces, add red dates and water with a mass ratio of 1-5:1-5 for hot water extraction to obtain primary red date juice; add water to mix wolfberry, and the mass ratio is 1-5: 1-5, to obtain primary wolfberry juice; crush the grapes to obtain primary grape juice, add 1.5% esterase, and stir for 3 hours; refer to Table 1 for the final material-liquid ratio and process of the above-mentioned primary juice extraction.

[0039] (2) Fruit juice compounding: mix primary jujube juice, primary wolfberry juice and primary grape juice, and the mass ratio of red dates, wolfberry and grapes is 6-9:1-3:1-3 to obtain primary mixed juice;

[0040] (3) Component adjustment: Add calcium carbonate and sucrose to the primary mixed juice to adjust the pH to 0.05%, and adjust the sugar content to 26%, and add potassium metabisulfite to sterilize SO 2The added amount is 40ppm to obtain secondary mixed juice.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com