Browning liquid used for printing circuit board

A printed circuit board and browning liquid technology, which is applied in the secondary treatment of printed circuits, the improvement of metal adhesion of insulating substrates, and the coating process of metal materials. It can solve blistering, poor peel strength performance, high temperature thermal shock It can solve the problems of weak bearing capacity and other problems, so as to achieve the effect of strong bonding ability, strong bearing capacity and good anti-peeling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

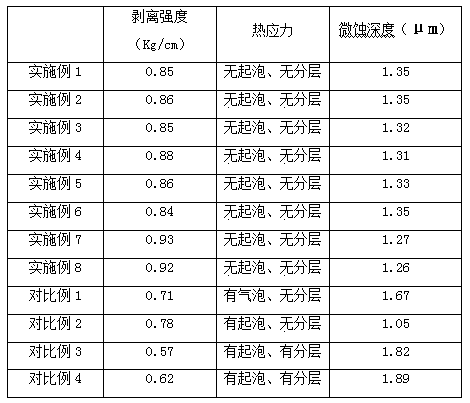

Examples

Embodiment 1

[0044] This embodiment provides a browning solution for printed circuit boards. The parts by weight of each component are shown in Table 1, wherein the inorganic acid is sulfuric acid with a mass fraction of 40%. The oxidizing agent is hydrogen peroxide. The corrosion inhibitor is benzotriazole. The stabilizer is benzenesulfonic acid. The inorganic salt is zinc sulfate. Described additive is methoxylated ethylene glycol, methyltriethoxysilane, polyimide, methoxylated ethylene glycol: methyltriethoxysilane: the weight ratio of polyimide is 1:2:0.5. Described plasticizer is dibutyl phthalate.

Embodiment 2

[0046] This embodiment provides a browning solution for printed circuit boards. The parts by weight of each component are shown in Table 1, wherein the inorganic acid is phosphoric acid with a mass fraction of 42%. The oxidizing agent is hydrogen peroxide. The corrosion inhibitor is 4-hydroxybenzotriazole. The stabilizer is ethylenediaminetetraacetic acid. The inorganic salt is zinc sulfate. Described additive is methoxylated ethylene glycol, methyltriethoxysilane, polyimide, methoxylated ethylene glycol: methyltriethoxysilane: the weight ratio of polyimide is 1:2.2:0.6. Described plasticizer is dibutyl phthalate.

Embodiment 3

[0048] This embodiment provides a browning solution for printed circuit boards. The parts by weight of each component are shown in Table 1, wherein the inorganic acid is nitric acid with a mass fraction of 45%. The oxidizing agent is hydrogen peroxide. The corrosion inhibitor is benzotriazole. The stabilizer is benzenesulfonic acid. The inorganic salt is zinc sulfate. Described additive is methoxylated ethylene glycol, methyltriethoxysilane, polyimide, methoxylated ethylene glycol: methyltriethoxysilane: the weight ratio of polyimide is 1:2.4:0.6. Described plasticizer is dibutyl phthalate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com