Fluorescent ceramic for white light illumination, preparation method and white light source device

A fluorescent ceramic and white light technology, applied in the field of fluorescent ceramics, white light source devices, and preparation, can solve the problems of lack, low color rendering index, uneven light output of laser lighting, etc., so as to improve the thermal shock resistance and solve the thermal shock resistance. Weak, avoid the effect of reducing the luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

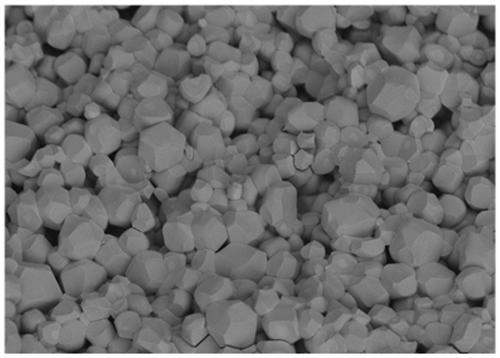

[0029] According to (Lu 0.79 Tb 0.2 Ce 0.01 ) 3 Al 5 o 12 Stoichiometric ratio, weigh high-purity lutetium nitrate (Lu(NO 3 ) 3 ), aluminum nitrate (Al(NO 3 ) 3 ), cerium nitrate (Ce(NO 3 ) 3 ), terbium nitrate (Tb(NO 3 ) 3 ) raw material, using urea as a complexing agent, put it into a hydrothermal reaction tank and keep it in an oven at 250°C for 48h, after washing and drying, put it in a muffle furnace and burn it at 600°C for 4h; then add magnesium oxide (MgO) and orthosilicic acid Ethyl ester (TEOS) was used as a sintering aid for ball milling, wherein the added amount of magnesium oxide (MgO) was 0.1% by mass fraction, and the added amount of tetraethyl orthosilicate (TEOS) was 0.6% by mass fraction. Put the mixed powder raw materials into a graphite mold, and put them in a plasma sintering furnace at 1700°C with a vacuum degree of 10 -3 Sintering under the condition of Pa for 30min, and finally annealing at 1450°C for 10h in a muffle furnace to obtain (Lu ...

Embodiment 2

[0031] According to (Lu 0.79 Tb 0.2 Ce 0.01 ) 3 Al 5 o 12 Stoichiometric ratio, weigh high-purity lutetium nitrate (Lu(NO 3 ) 3 ), aluminum nitrate (Al(NO 3 ) 3 ), cerium nitrate (Ce(NO 3 ) 3 ), terbium nitrate (Tb(NO 3 ) 3) raw material, using citric acid as a complexing agent, put it into a hydrothermal reaction tank and keep it in an oven at 250°C for 60h, after washing and drying, put it in a muffle furnace and burn it at 600°C for 4h; then add magnesium oxide (MgO) and orthosilicon Ethyl acetate (TEOS) was used as a sintering aid for ball milling, in which magnesium oxide (MgO) was added in an amount of 0.1% by mass fraction, and tetraethylorthosilicate (TEOS) was added in an amount of 0.6% by mass fraction. Put the mixed powder raw materials into a graphite mold, and put them in a plasma sintering furnace at 1600°C with a vacuum degree of 10 -3 Sintering under the condition of Pa for 40min, and finally annealing in a muffle furnace at 1450°C for 10h to obtai...

Embodiment 3

[0033] According to (Lu 0.79 Tb 0.2 Ce 0.01 ) 3 al 5 o 12 Stoichiometric ratio, weigh high-purity lutetium nitrate (Lu(NO 3 ) 3 ), aluminum nitrate (Al(NO 3 ) 3 ), cerium nitrate (Ce(NO 3 ) 3 ), terbium nitrate (Tb(NO 3 ) 3 ) raw material, using urea as a complexing agent, put it into a hydrothermal reaction tank and keep it in an oven at 250°C for 30h, wash and dry it with water, put it in a muffle furnace at 600°C for 4h and pre-fire it, then add magnesium oxide (MgO) and orthosilicic acid Ethyl ester (TEOS) was used as a sintering aid for ball milling, wherein the added amount of magnesium oxide (MgO) was 0.1% by mass fraction, and the added amount of tetraethyl orthosilicate (TEOS) was 0.6% by mass fraction. Put the mixed powder raw materials into a graphite mold, and put them in a plasma sintering furnace at 1500°C with a vacuum degree of 10 -3 Sintering under the condition of Pa for 50min, and finally annealing in a muffle furnace at 1450°C for 10h to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com