Lithium metal anode protective layer and preparation method and application thereof

A lithium metal negative electrode and metal protective layer technology, which is applied in the field of solid-state batteries, can solve the problems of affecting the battery cycle rate performance, reducing the battery cycle life, and increasing the battery impedance, so as to improve the cycle performance, prevent the generation of lithium dendrites, Effect of Reducing Interface Impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

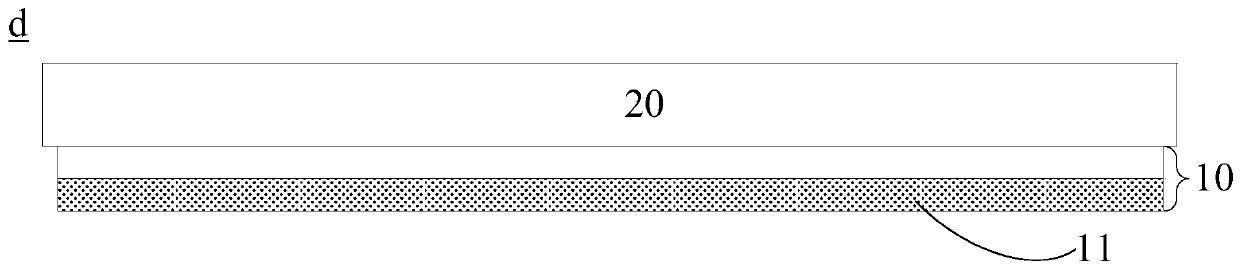

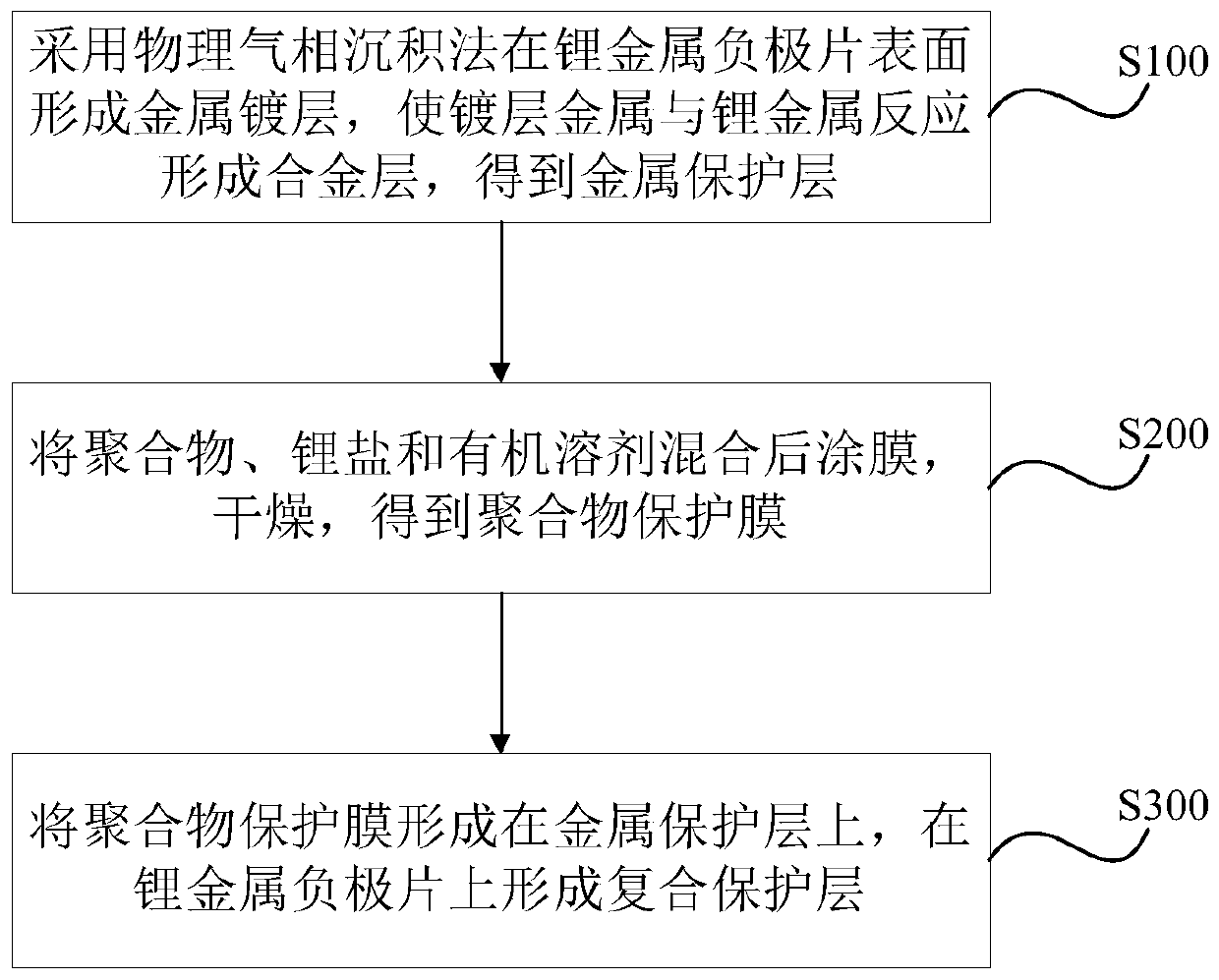

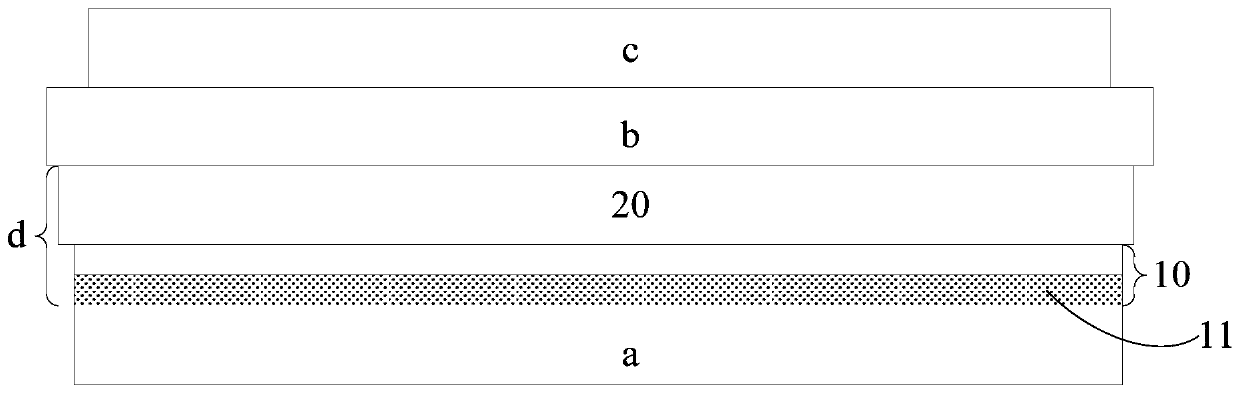

[0076] Under the environment of the drying room (dew point-40 ℃), a 10cm×10cm lithium foil is fixed on the evaporation mask and placed on the substrate plate of the evaporation chamber, and 0.4g metallic silver is placed on the evaporation boat (the material is Molybdenum, can also be tungsten or tantalum, etc.) fixed on the evaporation source, until the vacuum degree of the chamber reaches 10 -3 ~10 -5 After Pa, raise the substrate temperature to 80-150°C and start metal evaporation, gradually increase the evaporation arc current until the evaporation rate is stable at 0.01nm / s, continue to evaporate silver on the lithium metal surface at this speed, Stop the evaporation when the thickness of the evaporation layer reaches 100nm, and take it out after the lithium foil is cooled to room temperature to obtain a lithium metal negative electrode with a Li-Ag alloy protective layer.

[0077] Dissolve PEO and LiTFSI into anhydrous acetonitrile at a mass ratio of 3:1, and coat the f...

Embodiment 2

[0087] Under the environment of the dry room (dew point -40°C), a lithium foil with a diameter of 4 cm was placed on the sample stage as a substrate, and a silver foil with a diameter of 0.8 cm was placed at the sputtering head. -3 ~10 -5Sputtering is carried out under the vacuum degree of Pa, and the sputtering time is set to be 1 hour. After the sputtering is completed, the thickness of the metal coating is 500 nm, and finally a lithium metal negative electrode with a Li-Ag alloy protective layer is obtained.

[0088] Dissolve PEO and LiTFSI into anhydrous acetonitrile at a mass ratio of 3:1, and coat the film on a coating machine with a scraper gap of 400um. After the film is formed, the solvent is dried and then transferred to a vacuum drying oven for drying at 60°C. Dry for 24 hours to obtain a polymer protective layer with a thickness of 5 μm.

[0089] The above-mentioned metal protective layer of the lithium metal negative electrode with the Li-Ag alloy protective laye...

Embodiment 3

[0091] Under the environment of the dry room (dew point -40°C), a lithium foil with a diameter of 4 cm was placed on the sample stage as a substrate, and a silver foil with a diameter of 0.8 cm was placed at the sputtering head. -3 ~10 -5 Sputtering is carried out under the vacuum degree of Pa, and the thickness of the metal coating is 5 nm after the sputtering is completed, and finally a lithium metal negative electrode with a Li-Ag alloy protective layer is obtained.

[0092] Dissolve PEO and LiTFSI into anhydrous acetonitrile at a mass ratio of 3:1, and coat the film on a coating machine with a scraper gap of 400um. After the film is formed, the solvent is dried and then transferred to a vacuum drying oven for drying at 60°C. Dry for 24 hours to obtain a polymer protective layer with a thickness of 100 μm.

[0093] The above-mentioned metal protective layer of the lithium metal negative electrode with the Li-Ag alloy protective layer is opposed to the polymer protective la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com