Novel nylon material and preparation method thereof, and application of novel nylon material in 3D printing

A nylon, a new type of technology, applied in the field of nylon materials, can solve problems such as finding solutions for the molecular structure of nylon, and achieve the effects of improving mechanical properties, strong rigidity, and solving easy warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

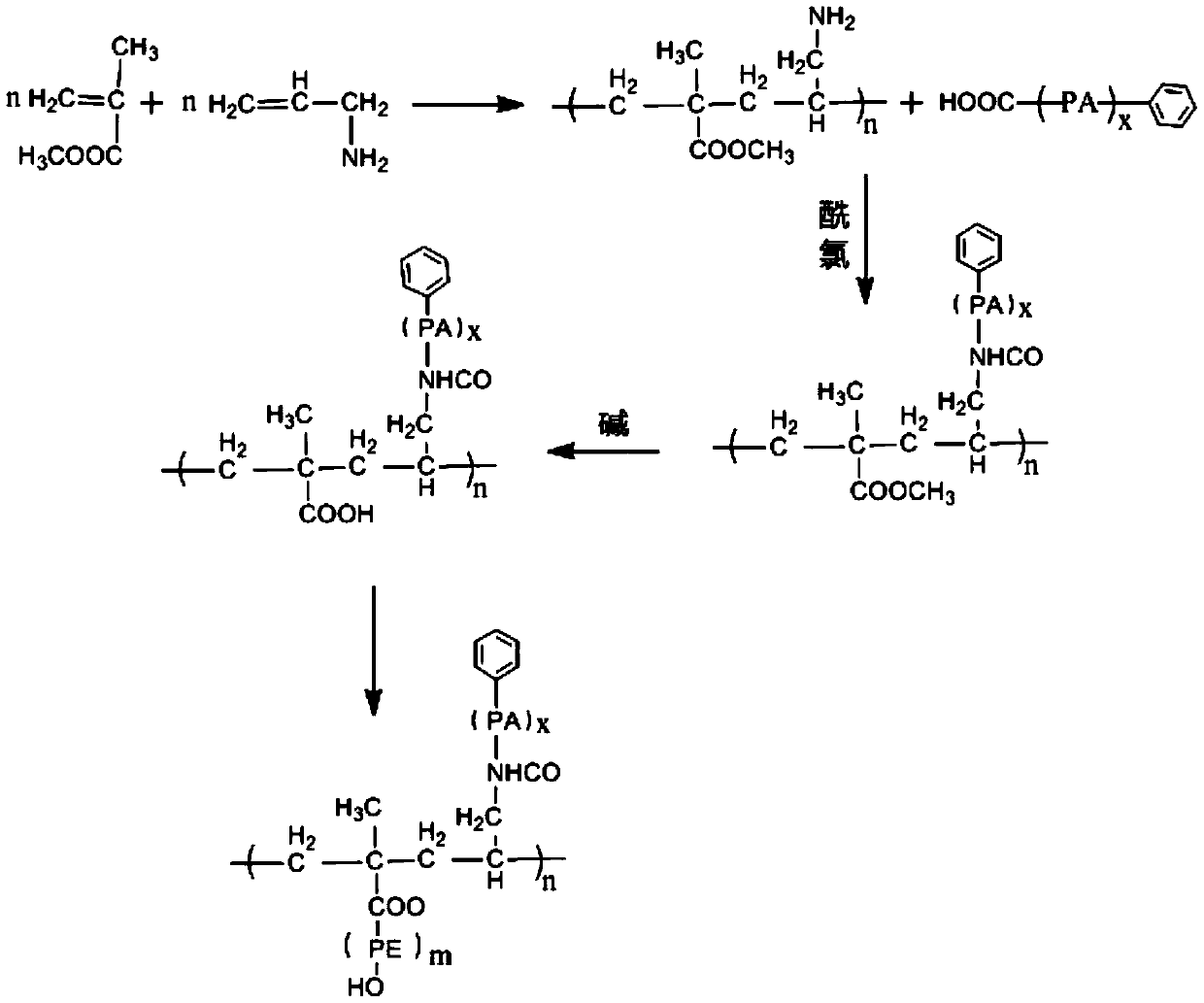

Method used

Image

Examples

Embodiment 1

[0042] 1) Disperse 1mol of methyl methacrylate and 1mol of allylamine in 5000ml of methanol and water in a mixed solvent with a volume ratio of 1:1, add 0.01mol of EGDMA, 0.2mol of PVP K90, and 0.01mol of AIBN to the system in sequence, and then React at 60°C for 25 hours in a nitrogen environment, dehydrate and dry to obtain polymer a, and the number average molecular weight of polymer a is 105103Da as detected by GPC;

[0043] 2) Disperse 2.5 mol of polyamide 12 (1000) in 5000 mL of N-methylpyrrolidone, react with 5 mol of thionyl chloride and 0.05 mol of polymer a under a nitrogen atmosphere at 5°C for 5 h, pour the product into hot water, and collect The precipitated product is polymer b, and the number average molecular weight of polymer b detected by GPC is 156890Da;

[0044] 3) Reflux 0.05mol of polymer b and 8mol of sodium hydroxide in methanol solvent at 80°C for 18h, remove the solvent by rotary evaporation, wash the obtained powder with sodium bicarbonate, dilute hy...

Embodiment 2

[0047] 1) Disperse 3 mol of ethyl acrylate and 1 mol of diallylamine in 20000 ml of methanol and water in a mixed solvent with a volume ratio of 1:1, add 0.03 mol of EGDMA, 0.3 mol of PVP K90, and 0.03 mol of AIBN to the system in turn, at 60 ℃, under nitrogen environment for 30 hours, dehydration and drying to obtain polymer a, the number average molecular weight of polymer a detected by GPC is 120965Da;

[0048] 2) Disperse 5 mol of polyamide 11 (1000) in 20,000 mL of N-methylpyrrolidone, react with 8 mol of oxalyl chloride and 0.05 mol of polymer a at 20°C under a nitrogen atmosphere for 0.5 h, pour the product into hot water, and collect the precipitate The product is polymer b, and the number average molecular weight of polymer b detected by GPC is 278539Da;

[0049] 3) Reflux 0.05mol of polymer b and 5mol of sodium hydroxide in methanol solvent at 60°C for 25 hours, remove the solvent by rotary evaporation, wash the obtained powder with sodium bicarbonate, dilute hydroch...

Embodiment 3

[0052] 1) Disperse 5 mol of ethyl acrylate and 1 mol of crotonic acid in 20000 ml of ethanol and water in a mixed solvent with a volume ratio of 1:1, add 0.02 mol of EGDMA, 0.5 mol of PVP K90, 0.1 mol of AIBN to the system in turn, at 70 ℃, Reaction under nitrogen environment for 20h, dehydration and drying to obtain polymer a, the number average molecular weight of polymer a detected by GPC is 113296Da;

[0053] 2) Disperse 4 mol of polyamide 11 (1000) in 20,000 mL of N-methylpyrrolidone, react with 8 mol of oxalyl chloride and 0.05 mol of polymer a at 10°C under a nitrogen atmosphere for 4 hours, pour the product into hot water, and collect the precipitated product That is, polymer b, the number average molecular weight of polymer b detected by GPC is 164008Da;

[0054] 3) Reflux 0.05mol polymer b and 10mol sodium hydroxide in methanol solvent at 75°C for 18h, remove the solvent by rotary evaporation, wash the obtained powder with sodium bicarbonate, dilute hydrochloric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com