Microbial capsule applied to dangerous rock mass reinforcement and construction process

A technology of microorganisms and dangerous rock mass, applied in the field of geotechnical engineering, can solve the problems that dangerous rock mass cannot form effective support, it is difficult to achieve protection, and the construction period is long, so as to improve connectivity and integrity, and overcome obvious brittleness , to ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

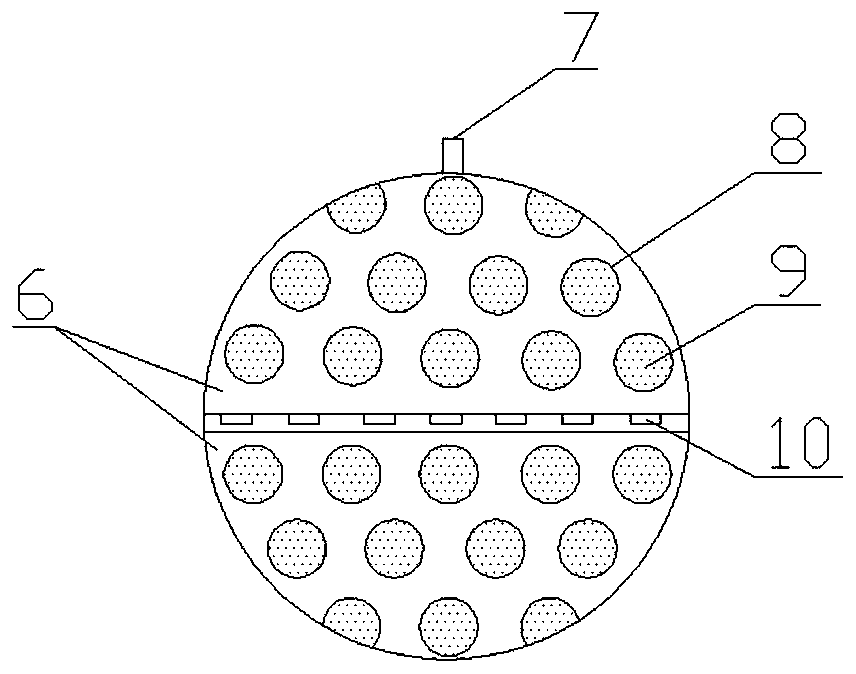

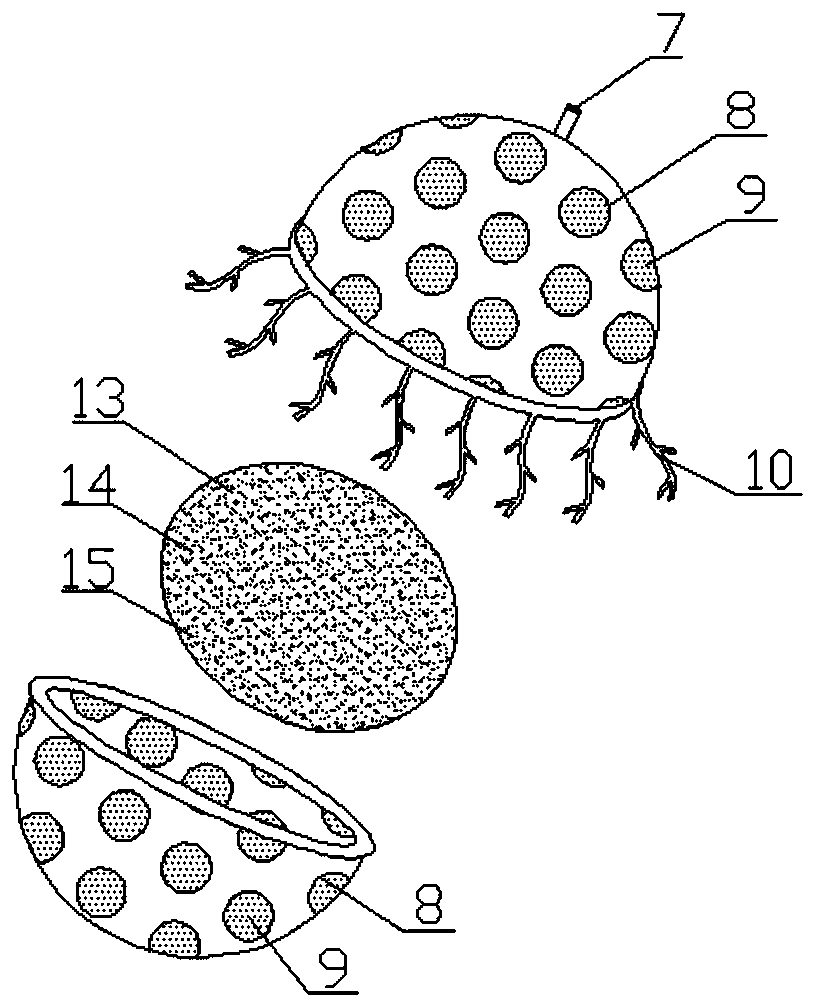

[0053] Such as figure 2 and image 3 A microbial capsule applied to the reinforcement of dangerous rock mass is shown, the microbial capsule includes a capsule shell and core material particles; the capsule shell includes a shell 6, roots 10, and a channel pipe 7; the shell 6 Spherical, circular through-holes 8 are distributed on the housing 6, a hole film 9 is attached to the circular through-holes 8, a channel pipe 7 is arranged on the upper surface of the housing 6, and a large circle of the spherical surface of the housing 6 is provided Several roots10.

[0054] Preferably, the core particle is composed of dry spore powder 13, nutrient substance 14 and calcium source substance 15; the capsule shell wraps the core particle to form a microbial capsule.

[0055] Further preferably, the dry spore powder 13 is one or more of Bacillus pasteurianus, Bacillus sarcina pasteurii, and Bacillus korsii.

[0056] Further preferably, the nutritional substance 14 includes peptone, bee...

Embodiment 2

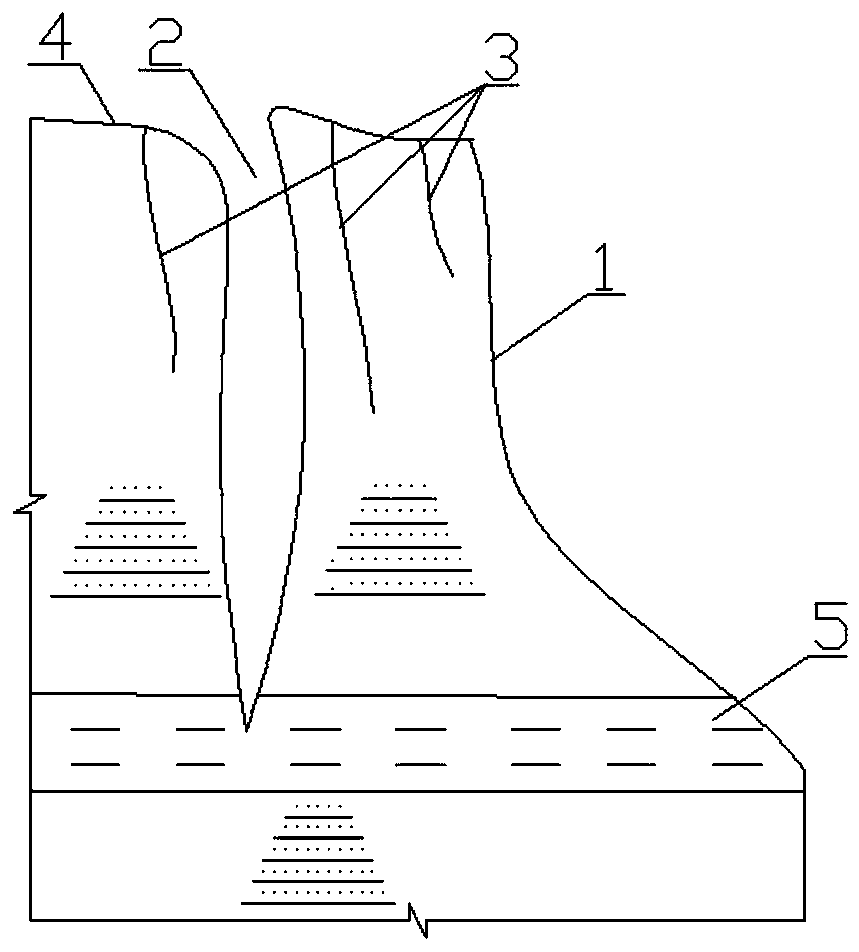

[0065] combine Figure 4 and Figure 5 , the construction technique that embodiment 1 microbial capsule is applied to dangerous rock mass reinforcement, comprises the following steps:

[0066] When the weather conditions are continuous sunny days,

[0067] Step1: Use unmanned aerial vehicle equipment to carry out engineering geological survey, find out the scope and scale of dangerous rock mass 1 and the extension of cracks in dangerous rock mass, estimate the required filling amount and the size gradation of microbial capsules.

[0068] Step2: Prepare a corresponding number of microbial capsules and put them in a dry storage box for later use.

[0069] Step3: Set up the operation platform at the dangerous rock mass that needs to be treated, set up temporary support and safety protection devices, and evenly mix the sand, fiber and microbial capsules on site for future use.

[0070] Step4: For the tiny cracks (3) on the dangerous rock mass, drill holes along the direction of...

Embodiment 3

[0076] When running into rainy days during construction, the difference with embodiment 2 is:

[0077] Step6: During the period of periodic water supply to the capillary 11, in rainy days, if the precipitation ≥ 10.0mm / d, reduce the water flow of the capillary 11 to ensure the water demand at the bottom of the crack, and activate the microbial capsule through rainwater infiltrating into the crack, thereby Seal the cracks; if the rainfall is <10.0mm / d, the amount of water flowing into the tube remains unchanged, and an appropriate amount of water is periodically injected into the capillary 11, and the microbial capsules are activated by manually controlling the amount of water to effectively seal the cracks.

[0078] Adopt the construction technology that embodiment 1 microbial capsule is applied to dangerous rock mass reinforcement, combine Figure 6-8 , in order to illustrate the implementation effect of the present invention, especially carry out relevant test indoors and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com