Farm chemical soluble granules and preparation method thereof

A soluble and granule technology, applied in the field of pesticides, can solve the problems of easy drift, environmental pollution, dust injury of industrial workers and pesticide applicators, etc., and achieve the effect of easy packaging, low water content and low transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

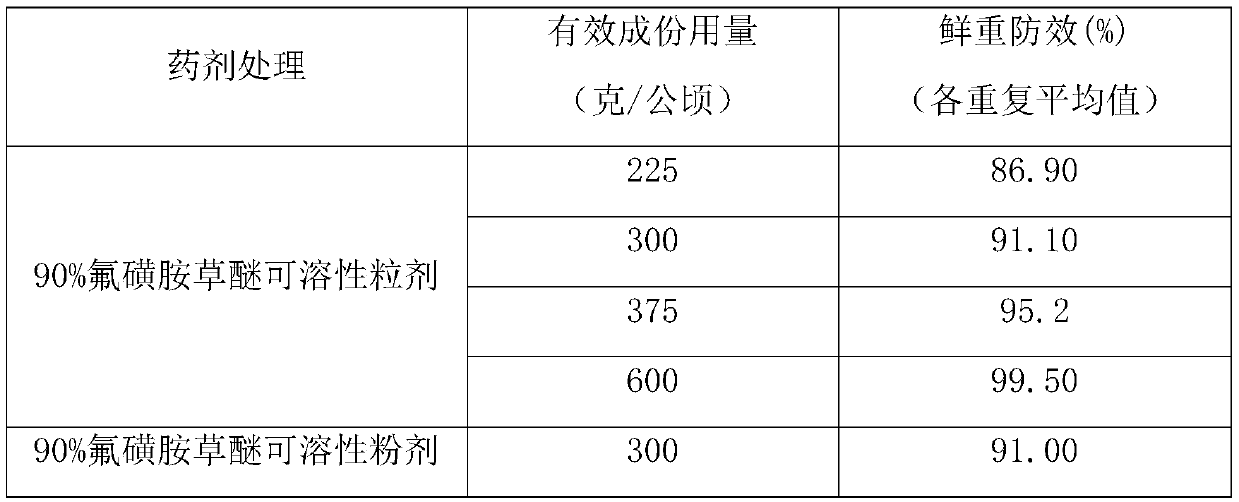

[0027] Preparation of 90% fomesafen soluble granules:

[0028] Add 107 grams of tap water, 100 grams of methanol, and 70 grams of 99% caustic soda (sodium hydroxide) to a 2000ml flat-bottomed beaker. Stir fully to dissolve the caustic soda, then slowly add 700 grams of 98.5% fomesafen under stirring. For the original medicine, until the original medicine of fomesafen is completely dissolved, add 8 grams of binder (glucose) and 15 grams of surfactant (alkylphenol polyoxyethylene ether: sodium dodecyl benzene sulfonate = 1:1) ) Continue to stir for 30 minutes to obtain 1000 g of fomesafen liquid, which is then transported to a small spray-drying prilling tower for spray granulation to obtain 760 g of fomesafen soluble granules.

[0029] With reference to the national standard B22169-2008, the mass content of the active ingredient fomesafen is 90.03% and the water content is less than 0.5% by the external standard method of liquid chromatograph.

Embodiment 2

[0031] Preparation of 60% fomesafen soluble granules

[0032] Add 215 grams of tap water, 80 grams of ethanol, 45 grams of 99% caustic soda (sodium hydroxide) into a 2000ml flat-bottomed beaker and stir thoroughly to dissolve the caustic soda, and then slowly add 440 grams of 98% fomesafen under stirring. Until the fomesafen original drug is completely dissolved, add 150 grams of ammonium sulfate filler, 40 grams of binder (glucose), 30 grams of surfactant (fatty alcohol polyoxyethylene ether, sodium dodecyl benzene sulfonate) =2:3) Continue to stir for 30 minutes to obtain 1000 g of fomesafen liquid, and then transport the water to a small spray-drying prilling tower for spray granulation to obtain 685 g of fomesafen soluble granules.

[0033] According to the national standard B22169-2008, the mass content of the active ingredient fomesafen measured by the external standard method of liquid chromatograph is 61.83% and the moisture content is less than 0.5%.

Embodiment 3

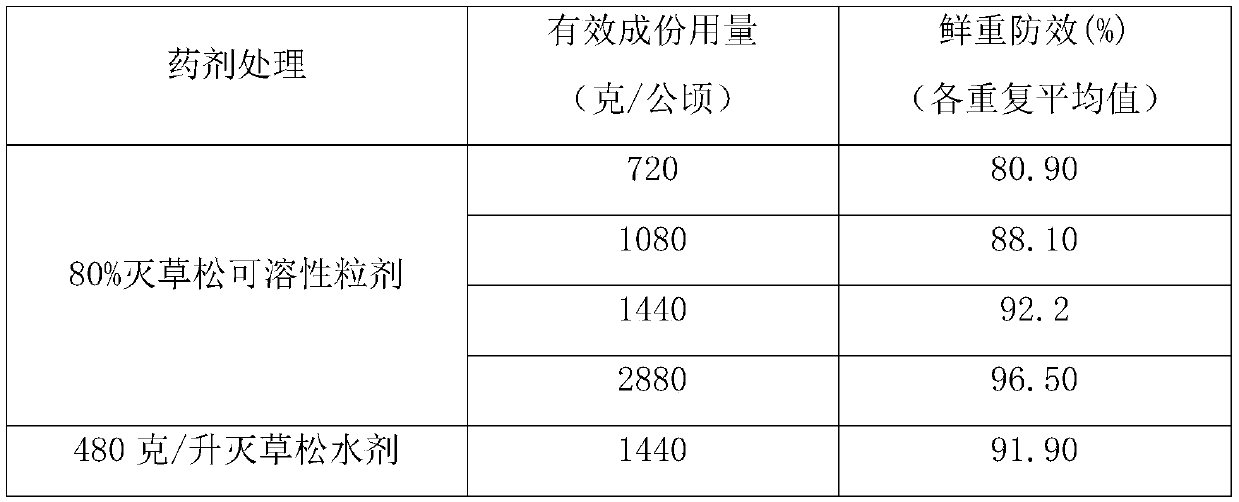

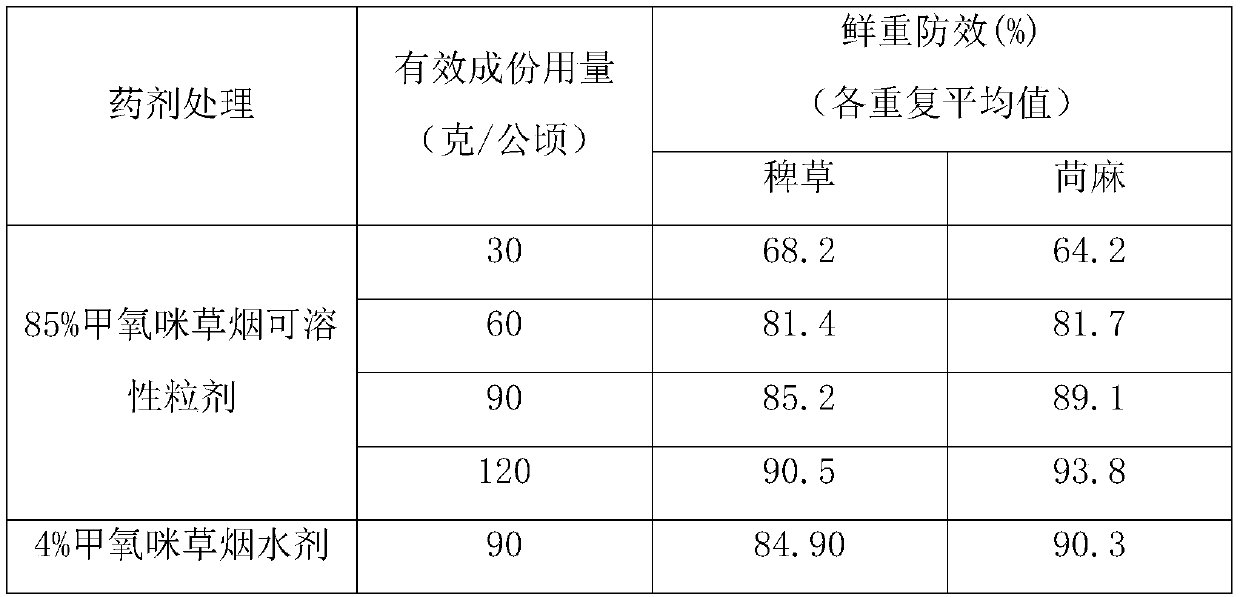

[0035] Preparation of 85% Benazone soluble granules

[0036] Add 170 grams of tap water, 100 grams of methanol, and 100 grams of 99% caustic soda (sodium hydroxide) into a 2000ml flat-bottomed beaker. Stir fully to dissolve the caustic soda, and then slowly add 600 grams of 98% mediaxone technical under stirring. , Until all the original medicinal powder is dissolved, add 10 grams of binder (carboxymethyl cellulose), 20 grams of surfactant (alkylphenol polyoxyethylene ether: sodium lauryl sulfonate = 1:1) Stirring is continued for 30 minutes to obtain 1000 grams of triazone water, which is then transported to a small spray-drying granulation tower for spray granulation to obtain 675 grams of triazone soluble granules.

[0037] The mass content of the active ingredient of the active ingredient of the liquid chromatograph is 85.22% and the moisture content is less than 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com