Monatomic iron-nitrogen co-doped carbon electrocatalyst as well as preparation method and application thereof

An electrocatalyst and co-doping technology, applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of insufficient activity, poor chimera effect, low catalyst selectivity, etc., and achieve high selectivity, low overpotential, The effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) 32mmol of 2-methylimidazole and 24mg of iron phthalocyanine (FePc) were added to 40mL of methanol, and stirred magnetically for 10min to uniformly mix to obtain a mixed solution; 4mmol of zinc nitrate hexahydrate (Zn(NO) 3 ) 2 ·6H 2 0) join in 40mL methanol, magnetic stirring 10min to mix uniformly, obtain the methanol solution of zinc nitrate;

[0045] (2) The methanol solution of zinc nitrate was added to the mixed solution, and after magnetic stirring at room temperature for 24 h, centrifuged and washed three times with methanol and deionized water, respectively, and vacuum dried at 70 °C for 12 h to obtain the metal organic framework ZIF-8 package. The iron phthalocyanine composite material;

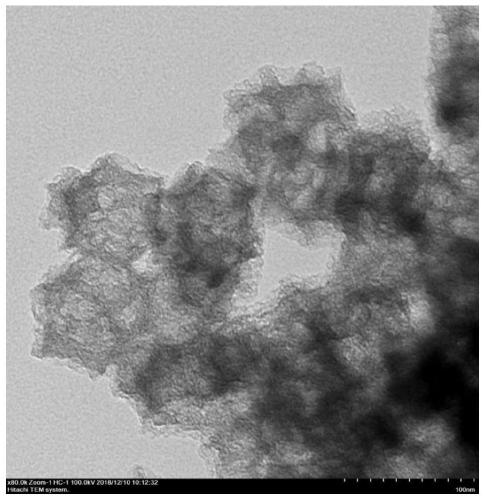

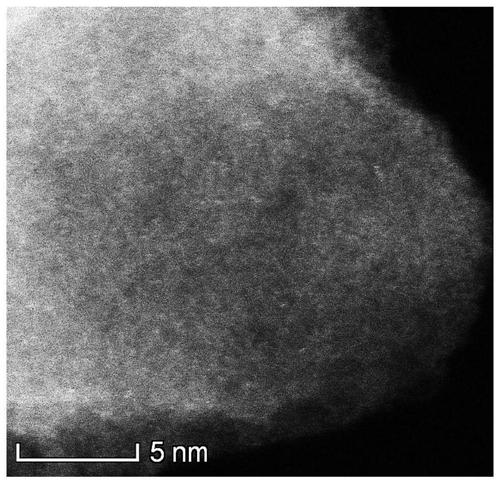

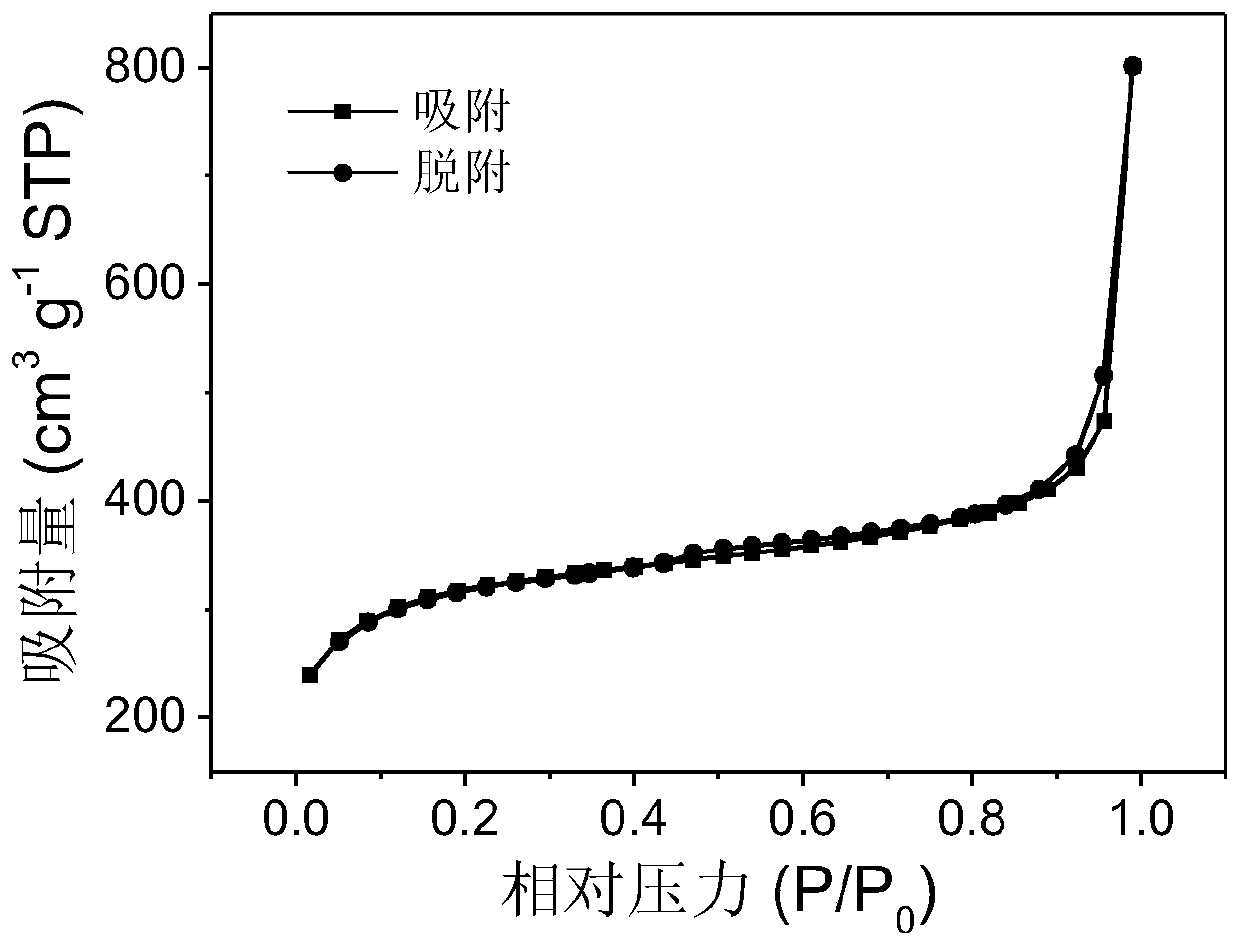

[0046] (3) The prepared composite material was calcined at 1000 °C under nitrogen atmosphere, and the heating rate was 5 °C min -1 , the calcination time was 3 h, and the calcined product was a single-atom iron-nitrogen co-doped carbon electrocatalyst containing iron ox...

Embodiment 2-4

[0050] According to the preparation method of Example 1, the calcination temperature in step (3) was changed to 700° C., 800° C. and 900° C., respectively, and the remaining steps remained unchanged. The BET specific surface area of the obtained catalyst was 469 m, respectively. 2 g -1 , 693m 2 g -1 and 775m 2 g -1 , the pore volume is 0.36cm, respectively 3 g -1 , 0.50cm 3 g -1 and 0.69cm 3 g -1 , the pore size distribution is the same as that of the catalyst in Example 1, including micropores with pore diameters below 3 nm, mesopores with 3-5 nm and 29-32 nm.

Embodiment 5-7

[0052] According to the preparation method of Example 1, the addition amount of iron phthalocyanine in step (1) was changed to 8 mg, 16 mg and 48 mg respectively, and the remaining steps remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com