Method for synthesizing aminoacetonitrile hydrochloride from hydrocyanic acid

A technology of aminoacetonitrile hydrochloride and aminoacetonitrile, which is applied in the preparation of carboxylic acid nitriles, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of large amount of wastewater, lengthy process, and increased wastewater treatment costs. Achieve the effects of mild reaction conditions, simple process, high appearance and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

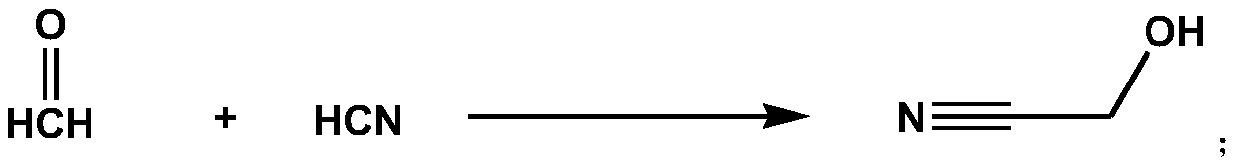

[0029] 1) Synthesize hydroxyacetonitrile according to the general process;

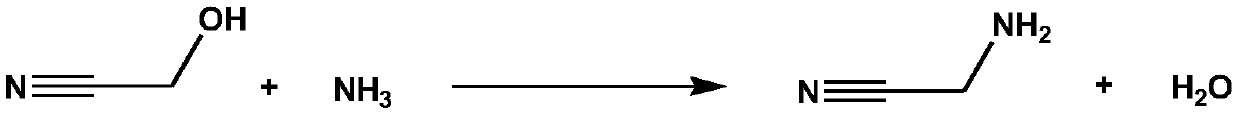

[0030] 2) Put 102 grams of 25% ammonia water into a 500 mL four-necked reaction flask, start stirring, control the temperature at 20-30°C, slowly add 114 grams of 50% hydroxyacetonitrile dropwise, and keep stirring for 1.5 hours. Deamination yields aminoacetonitrile.

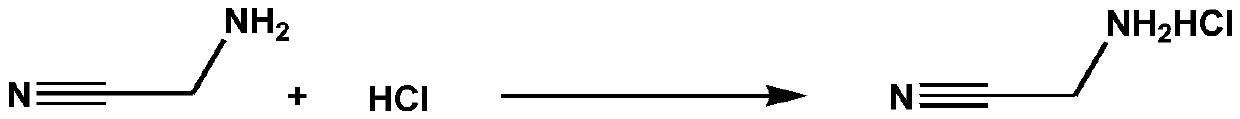

[0031] 3) Control the temperature at 20-30° C., slowly add 183 grams of 30% hydrochloric acid dropwise into the reaction flask. Keep warm and stir for 2 hours. Dehydrochlorination, low-temperature negative pressure concentration to a certain amount of water, cooling crystallization, filtration, vacuum drying to obtain the dry product of aminoacetonitrile hydrochloride, the appearance of which is off-white crystalline powder. The weight is 75.5 grams, and the yield is 81.6% (based on hydroxyacetonitrile). The content is 99.3%.

Embodiment 2

[0033] 1) Synthesize hydroxyacetonitrile according to the general process;

[0034] 2) Put 114 grams of 50% hydroxyacetonitrile into a 500 mL four-necked reaction flask. Stirring was started, the temperature was controlled at 20-30°C, and 25.5 grams of ammonia gas was quickly introduced. Keep stirring for 1.5 hours. Deamination obtains aminoacetonitrile;

[0035] 3) Control the temperature at 20-30°C at 30°C, and slowly inject 55 grams of hydrogen chloride gas into the reaction bottle. Keep warm and stir for 2 hours. Dehydrochlorination, low-temperature negative pressure concentration to a certain amount of water, cooling crystallization, filtration, vacuum drying to obtain the dry product of aminoacetonitrile hydrochloride, the appearance of which is off-white crystalline powder. The weight is 76 grams, and the yield is 82.2% (based on hydroxyacetonitrile). The content is 99.6%.

Embodiment 3

[0037] 1) Synthesize hydroxyacetonitrile according to the general process;

[0038] 2) Put 75 grams of 25% ammonia water into a 500 mL four-necked reaction bottle. Stirring was started, the temperature was controlled at 20-30°C, and 114 grams of 50% hydroxyacetonitrile was slowly added dropwise. Keep stirring for 1.5 hours. Deamination yields aminoacetonitrile.

[0039] 3) Control the temperature at 20-30° C., slowly add 134 grams of 30% hydrochloric acid dropwise into the reaction bottle. Keep warm and stir for 2 hours. Dehydrochlorination, low-temperature negative pressure concentration to a certain amount of water, cooling crystallization, filtration, vacuum drying to obtain the dry product of aminoacetonitrile hydrochloride, the appearance of which is off-white crystalline powder. The weight is 74 grams, and the yield is 80% (calculated as hydroxyacetonitrile). The content is 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com