Preparation method of biodiesel

A technology for biodiesel and glycerol, applied in the field of oleochemical industry, can solve the problems of difficulty in separating biodiesel and glycerol, reducing the yield of biodiesel and glycerol, difficulty in catalyst regeneration, etc., and achieves the regeneration and reuse of catalyst raw material sources and the source of catalyst raw materials. Wide range of effects to reduce saponification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The biodiesel raw material used in Example 1 is palmitic acid oil (acid value 160mgKOH / g), and its content distribution of fatty acid methyl ester is shown in Table 1.

[0021] Table 1 Content table of each fatty acid methyl ester in biodiesel prepared from palmitic acid oil

[0022] Element C 12:0

C 14:0

C 16:0

C 18:0

C 18:1

C 18:2

Mass fraction % 0.15 1.08 41.03 5.10 43.55 9.09

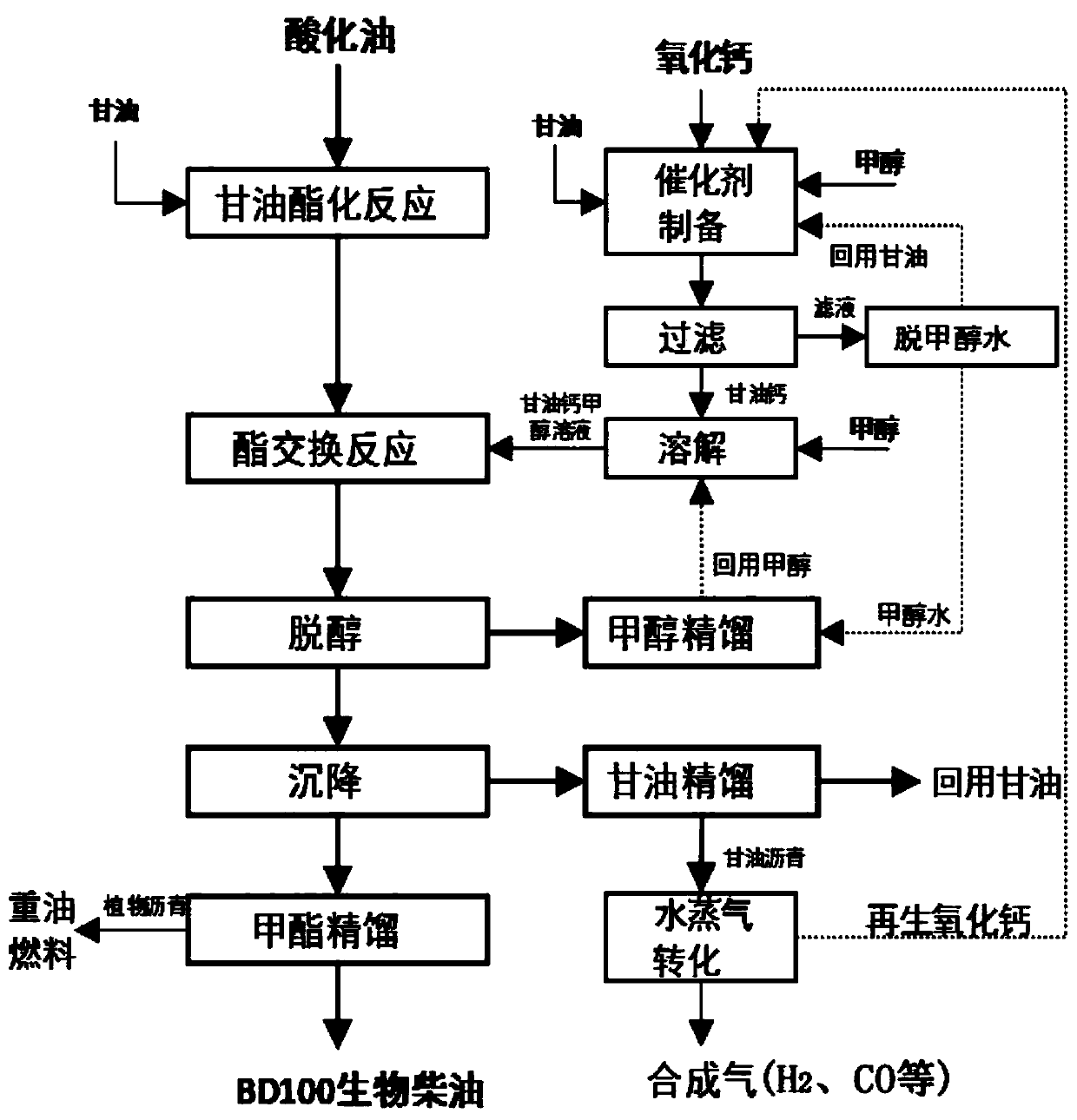

[0023] The technical process for preparing biodiesel in this embodiment is as follows: figure 1 As shown, the process for preparing biodiesel includes the following processes:

[0024] 1) Glycerol esterification reaction: After the raw palmitic acid oil is preheated to 240°C, glycerin is added for glycerin esterification reaction (fresh glycerin is used for the first production, and recycled glycerin can be used in the future), and the glycerol esterification temperature is controlled at 240°C, reaction time 2 hours;

[0025] 2) Transesterif...

Embodiment 2

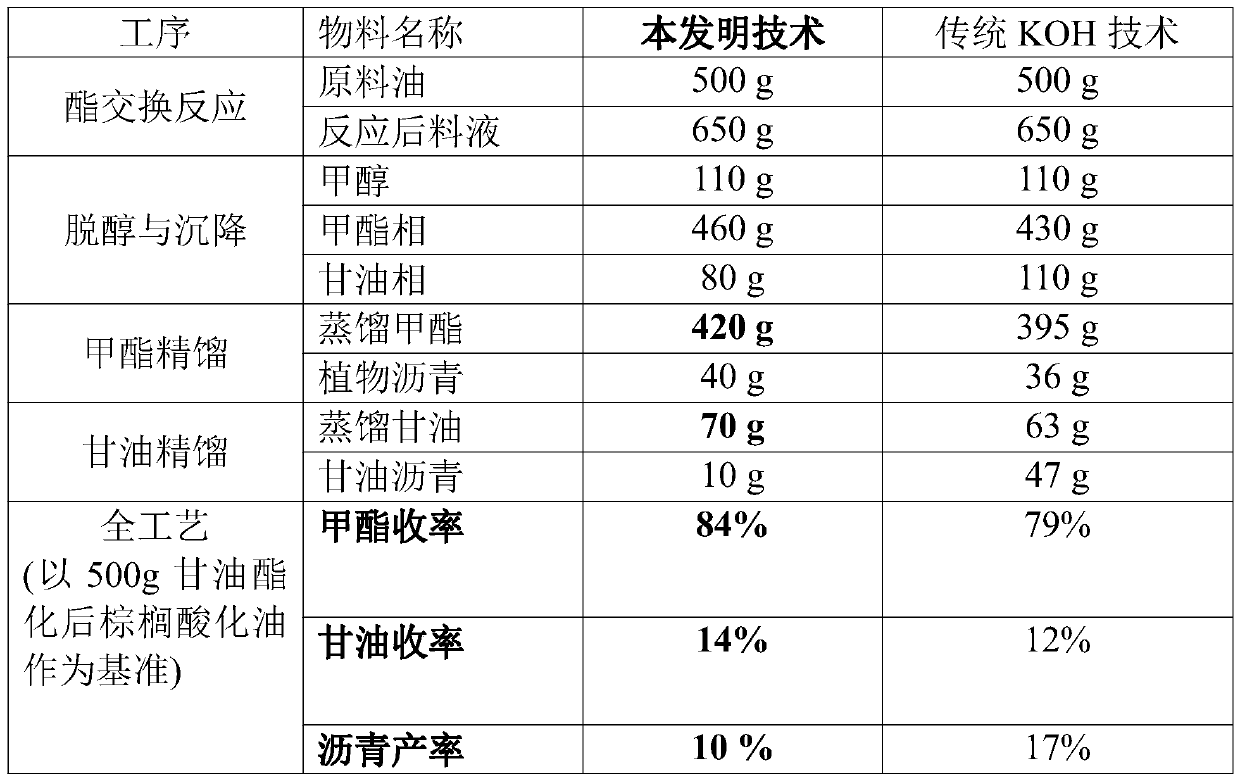

[0037] Embodiment 2 compares the effect of calcium glycerol catalyst and traditional KOH catalyst in transesterification reaction

[0038] The technology of the present invention: the 3.4g calcium oxide regenerated in Example 1 is used as raw material to prepare calcium glycerol, and the preparation temperature is 40° C. (the remaining conditions of catalyst preparation are with reference to Example 1). The prepared calcium glycerol catalyst was dissolved in methanol at 55° C. to form a calcium glycerol methanol solution. Get 150 g of the calcium glycerol methanol solution prepared in Example 2, and 500 g of the feed solution after the glycerol esterification reaction in Example 1, carry out transesterification at 60°C (the amount of calcium glycerol is 1.0 wt% of the oil weight), and the reaction time is 3h . After the transesterification reaction was finished, through the processes of dealcoholization, sedimentation, glycerin rectification and methyl ester rectification, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com