In-situ preparation method of metal fiber reinforced composite film

A metal fiber and reinforced composite technology, which is applied in metal material coating technology, ion implantation plating, gaseous chemical plating, etc., can solve the problem that it is difficult to avoid fiber agglomeration, inseparable from surface engineering technology, complex preparation process, etc. problems, to achieve good application prospects, reduce the difficulty of preparation, and avoid the effect of fiber agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

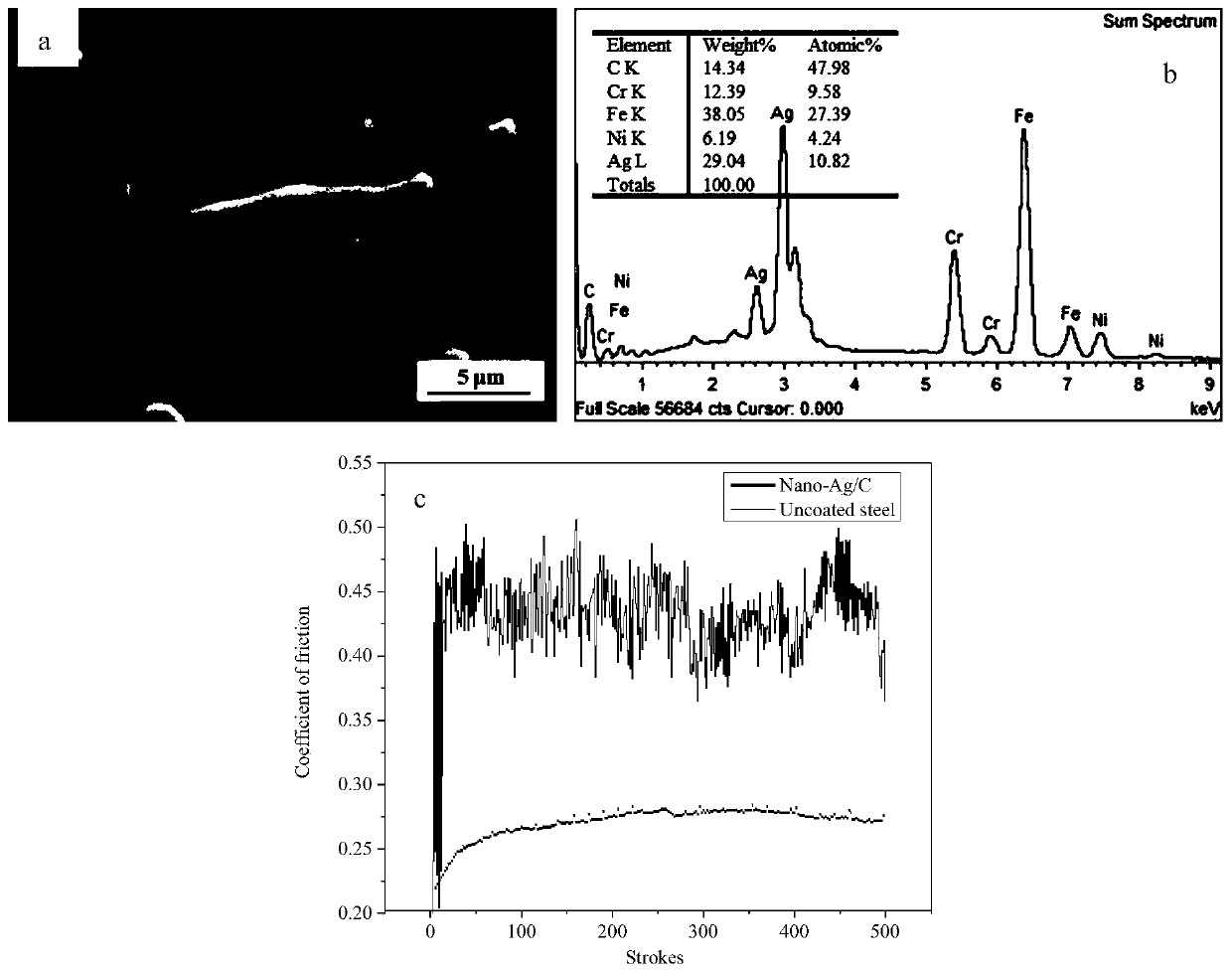

[0041] Embodiment 1, the preparation of silver wire reinforced composite film

[0042] In this example, a method for preparing an in-situ silver wire reinforced carbon-based composite film is provided. The preparation process mainly includes the following steps:

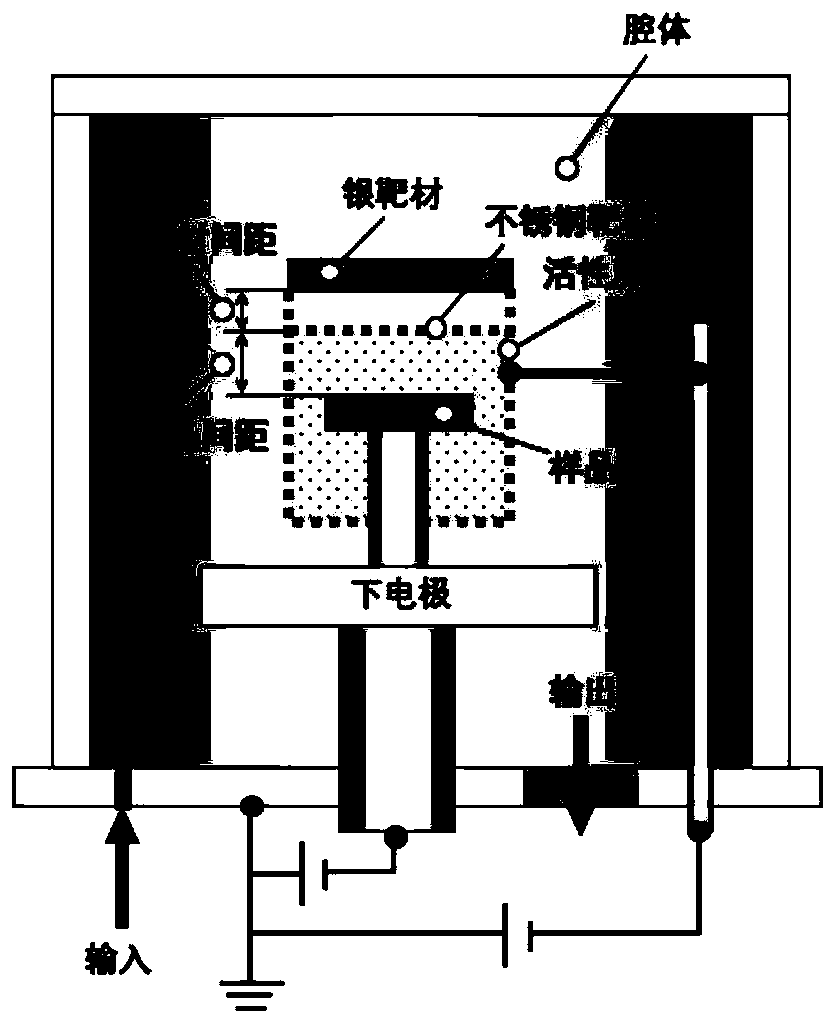

[0043] Provide a cylindrical 316 stainless steel substrate (25mm×3mm), the upper surface is polished and cleaned with alcohol ultrasonic waves, and then placed on the lower plate sample stage in the reaction chamber, the substrate and the substrate are separated by a non-conductive alumina ceramic pad The lower plate sample stage is spaced (so that the sample is at floating potential). Place the stainless steel active screen mesh cover on the sample. The active screen mesh cover is composed of two parallel targets. The hollow target material below is 316 stainless steel, and the target material above is 99.99% silver plate. The distance between the substrate and the target below is 20 mm, and the distance between the ...

Embodiment 2

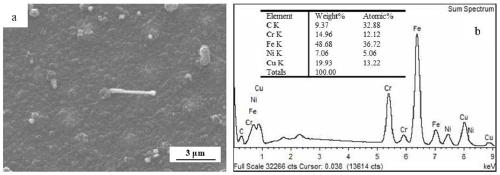

[0047] Example 2, Preparation of In-situ Growth Copper Wire Reinforced Carbon-based Composite Film

[0048] This example provides a preparation process for in-situ growth of copper wire reinforced carbon-based composite film, which mainly includes the following steps:

[0049] A silicon substrate is provided, and the surface is ultrasonically cleaned with alcohol, and then placed on the lower plate in the plasma reaction chamber, and the height of the substrate is adjusted with an alumina ceramic block. The configuration of the stainless steel active screen grille is similar to the configuration in Example 1, the lower hollow target is 316 stainless steel, and the upper target is 99.99% copper plate. The distance between the sample and the target below is 20 mm, and the distance between the two targets is 6 mm.

[0050] After the sample is placed, vacuumize the reaction chamber to 0.07mbar, then feed high-purity hydrogen into the chamber, adjust the pressure in the chamber to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com