Wood preservative and preparation method thereof

A wood preservative and quaternary ammonium salt technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve problems such as anti-corrosion and poor anti-bacterial effect, achieve excellent anti-bacterial and anti-bacterial properties, improve preparation uniformity, and ensure anti-corrosion. effect of the drug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

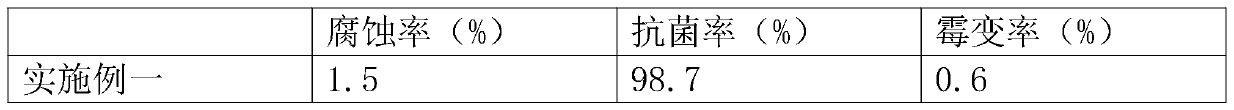

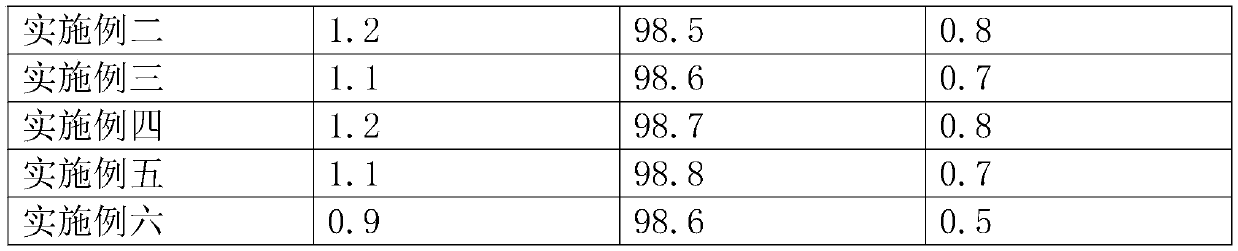

Examples

Embodiment 1

[0016] The wood preservative components include 10 parts of alkoxymethyl decyl dimethyl boron tetrafluoride quaternary ammonium salt, 4 parts of polyethylene glycol, 2 parts of nano-silver oxide, 3 parts of diatomaceous earth, 4 parts of delithification, 4 parts of bentonite, 2 parts of platycodon saponin, 3 parts of polyacrylonitrile-based carbon fiber, 4 parts of cybendazole, 5 parts of nano-silicon dioxide, 3 parts of carbon tetrachloride, dodecyl dimethyl benzyl 4 parts of ammonium chloride, 5 parts of propylene carbonate, and 3 parts of chitosan.

[0017] The preparation method of this embodiment comprises the following steps:

[0018] A. After mixing diatomite, montmorillonite and bentonite, add them into a ball mill for ball milling to obtain mixture A;

[0019] B. Then put the mixture A into the stirring tank, then add dimethyl boron tetrafluoride quaternary ammonium salt, polyethylene glycol, nano-silver oxide, cybendazole, dodecyl dimethyl benzyl chloride Ammonium,...

Embodiment 2

[0024] The wood preservative components include 20 parts of alkoxymethyl decyl dimethyl boron tetrafluoride quaternary ammonium salt, 10 parts of polyethylene glycol, 4 parts of nano-silver oxide, 9 parts of diatomaceous earth, 10 parts of delithification, 10 parts of bentonite, 6 parts of platycodon saponin, 9 parts of polyacrylonitrile-based carbon fiber, 10 parts of cybendazole, 12 parts of nano silicon dioxide, 9 parts of carbon tetrachloride, dodecyl dimethyl benzyl 10 parts of ammonium chloride, 15 parts of propylene carbonate, and 9 parts of chitosan.

[0025] The preparation method of this embodiment comprises the following steps:

[0026] A. After mixing diatomite, montmorillonite and bentonite, add them into a ball mill for ball milling to obtain mixture A;

[0027] B. Then put the mixture A into the stirring tank, then add dimethyl boron tetrafluoride quaternary ammonium salt, polyethylene glycol, nano-silver oxide, cybendazole, dodecyl dimethyl benzyl chloride Am...

Embodiment 3

[0032] The wood preservative components include 12 parts of alkoxymethyl decyl dimethyl boron tetrafluoride quaternary ammonium salt, 5 parts of polyethylene glycol, 3 parts of nano-silver oxide, 4 parts of diatomaceous earth, 5 parts of delithification, 5 parts of bentonite, 4 parts of platycodon saponin, 4 parts of polyacrylonitrile-based carbon fiber, 5 parts of cybendazole, 7 parts of nano-silicon dioxide, 4 parts of carbon tetrachloride, and dodecyl dimethyl benzyl 6 parts of ammonium chloride, 8 parts of propylene carbonate, and 5 parts of chitosan.

[0033] The preparation method of this embodiment comprises the following steps:

[0034] A. After mixing diatomite, montmorillonite and bentonite, add them into a ball mill for ball milling to obtain mixture A;

[0035] B. Then put the mixture A into the stirring tank, then add dimethyl boron tetrafluoride quaternary ammonium salt, polyethylene glycol, nano-silver oxide, cybendazole, dodecyl dimethyl benzyl chloride Ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com