Graphite paper current collector, negative electrode and preparation method

A technology of graphite paper and current collector, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problem of unable to continuously improve the specific capacity of the battery, achieve good cycle stability, improve the overall specific capacity, and stabilize the charge-discharge capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0054] The preparation method of embodiment A graphite paper:

[0055] Take the 100HN polyimide film of DuPont's Kapton series as an example, its basic parameters are as follows: 25um thick, the highest tensile strength is 231MPa, the maximum elongation is 72% (23°C) and the tensile modulus is 2.5GPa Wait.

[0056] Cut it into a specific shape (rectangle, square, circle, triangle, rhombus, hexagon, etc.) and size (depending on the situation) as needed. The following is an example of a square of 10 cm by 10 cm;

[0057] Next, the cut polyimide film was first cleaned with ultrapure water ultrasonic (frequency 40KHz, power range 120W) for 15 minutes, then ultrasonically cleaned with ethanol for 15 minutes, and repeated cleaning three times to remove impurities;

[0058] Next, place one or more pieces of the cleaned polyimide film between two flat graphite templates, pressurize and fix it with a pressure of 5MPa to prevent deformation caused by the subsequent high-temperature car...

Embodiment B

[0064] The preparation of embodiment B graphite paper current collector

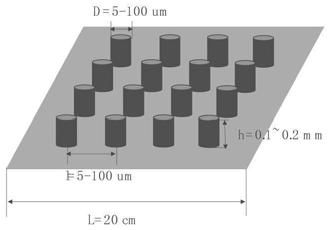

[0065] The template used is a stainless steel metal plate, which is prepared by etching. The structural features are as follows: image 3 shown.

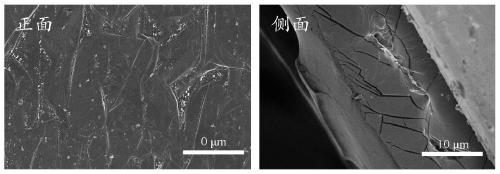

[0066] Spread the graphite paper prepared in Example A on the surface of the stainless steel template, place it in a roller press, adjust the rolling thickness, and prepare graphite paper with an array hole structure (the holes do not penetrate the graphite paper). Specifically, the prepared graphite paper is placed on the surface of a steel plate (such as image 3 Shown), the specific parameters in the above preparation process are: the thickness of the stainless steel template is 2 mm, the thickness of the graphite paper is 20um, and the rolling thickness can be adjusted to 2010um. The final highly oriented graphite paper current collector with array hole structure is as follows: Figure 4 shown.

Embodiment 1

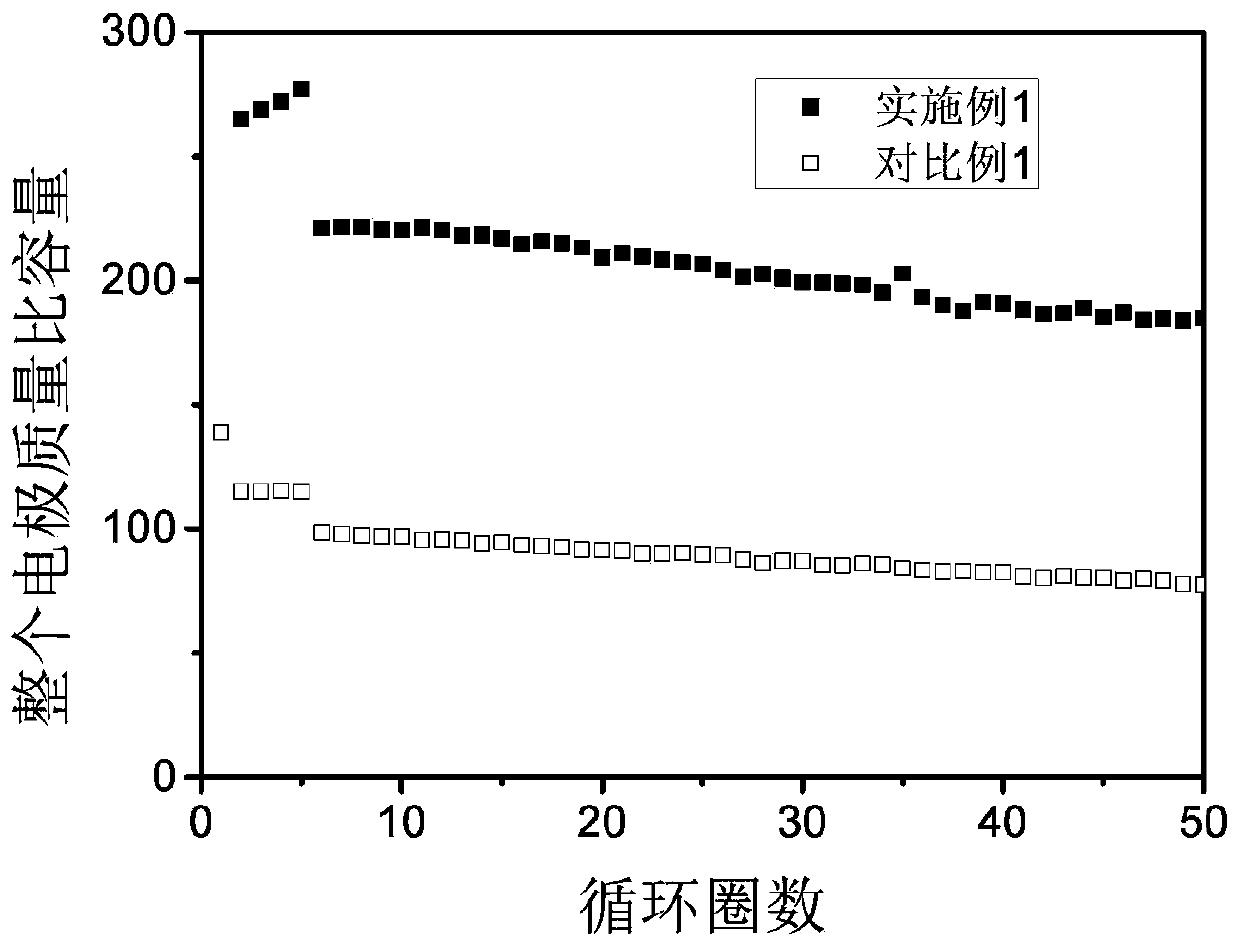

[0068] At room temperature, the thickener carboxymethylcellulose (CMC) powder and ultrapure deionized water were mixed at a ratio of 1.5:98.5, and stirred at room temperature for 12 hours to obtain a transparent viscous colloidal solution. According to the mass ratio of active material nano-scale silicon / carbon:: carbon nanotube (CNT): CMC = 8:1:1, add each component material, and ball mill and mix for 4 hours to obtain the negative electrode aqueous slurry. According to the conventional production process of lithium-ion button batteries, the aqueous negative electrode slurry is coated on the highly oriented graphite paper current collector with array hole structure prepared in Example B by the method of wet film preparation, dried and desiccated. In the water deoxygenation process, the dry film is punched by the punching equipment to cut the graphite paper collector to obtain the negative electrode sheet. In the glove box, assemble the button-type half-battery with metal lith...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com