Wetland sewage purification system

A sewage purification and wetland technology, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as power consumption, increased operating costs, and lack of scientific monitoring of effects , to achieve the effect of reducing on-site operators, improving the efficiency of sewage treatment, and improving the effect of water purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

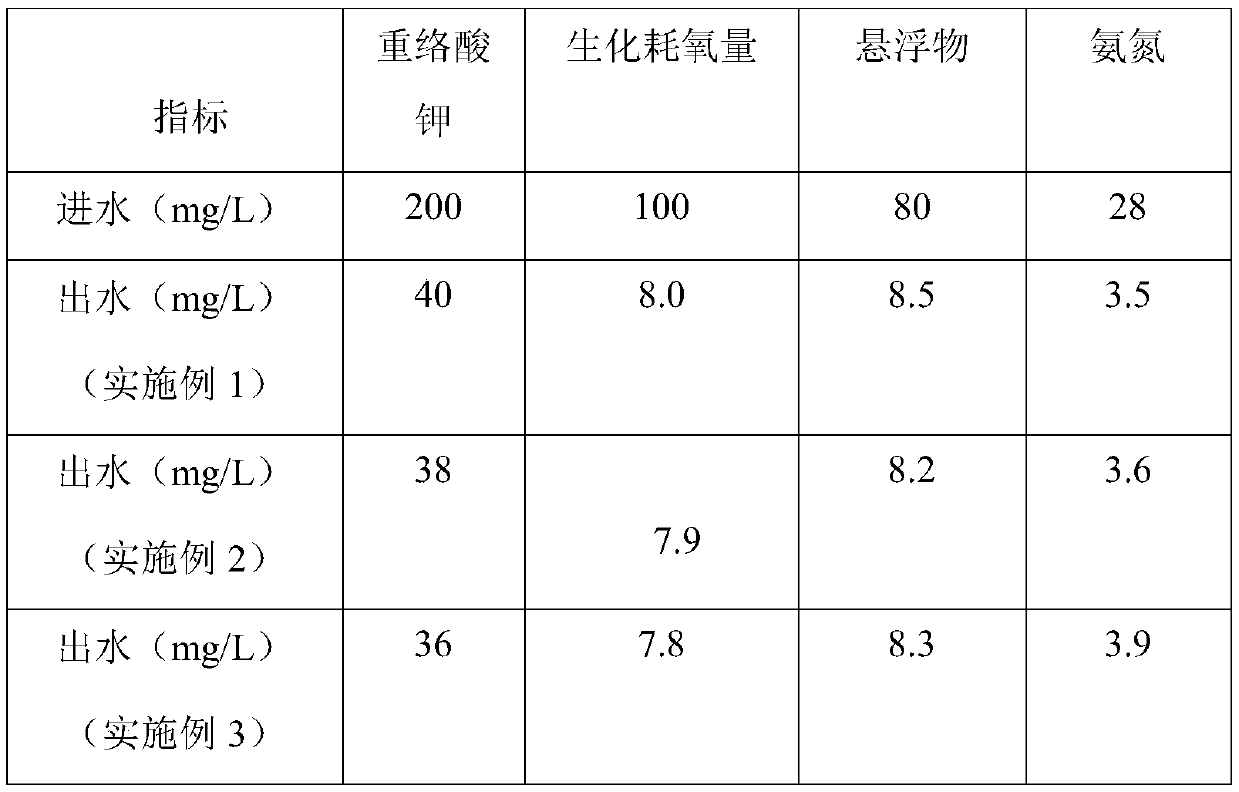

Embodiment 1

[0038] Embodiment 1 provides a wetland sewage purification system, comprising:

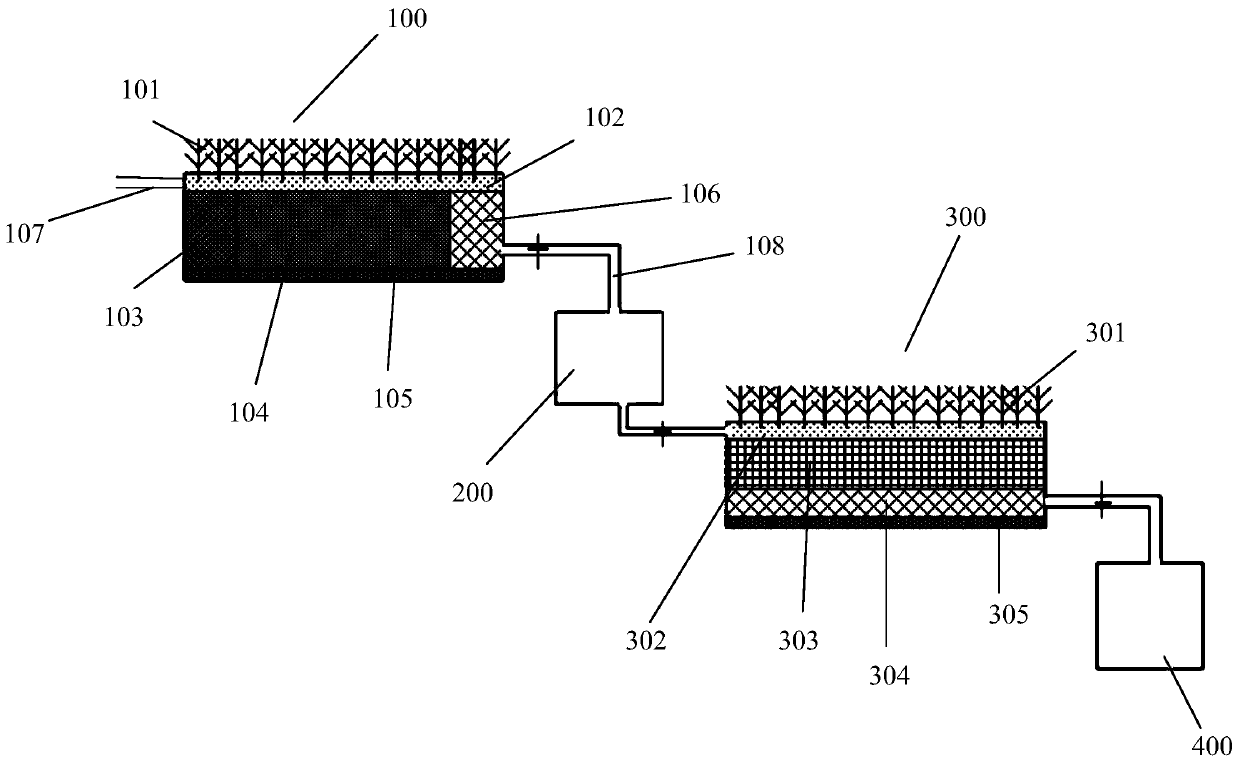

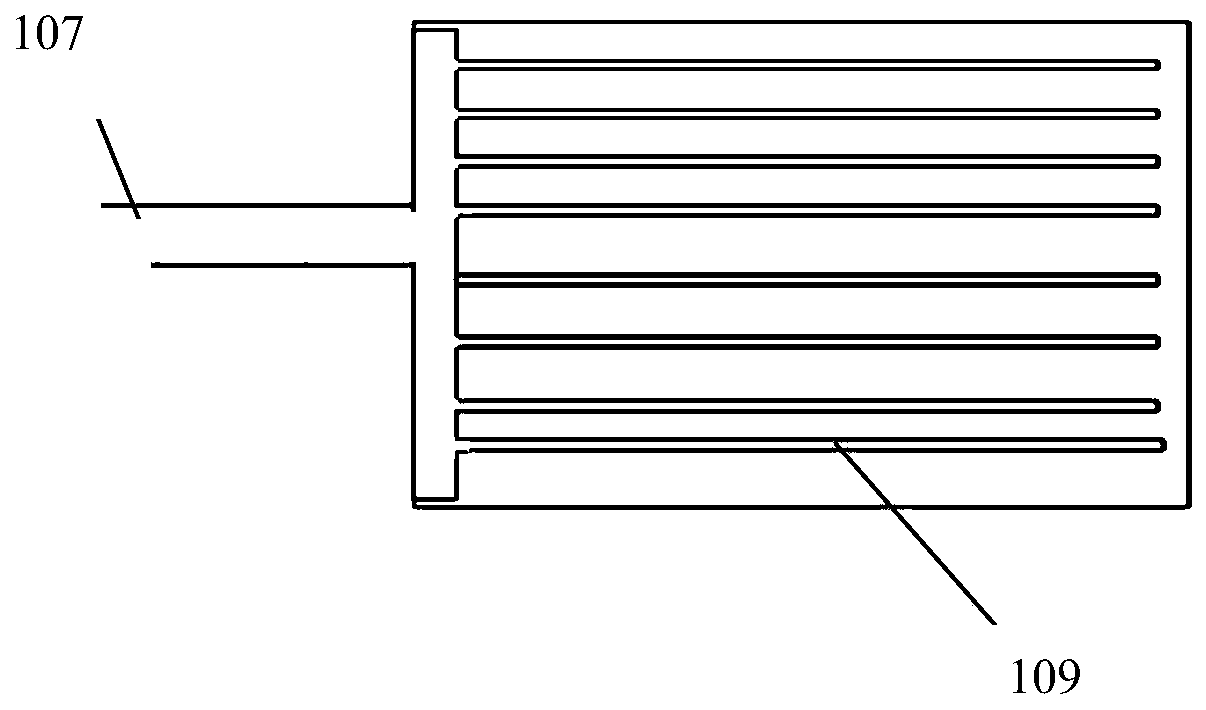

[0039] The first wetland tank 100, the first sedimentation tank 200, the second wetland tank 300, and the second sedimentation tank 400 are connected sequentially from top to bottom, wherein,

[0040] The first wetland pool 100 includes:

[0041] reed vegetation layer 101;

[0042] Planting soil layer 102, which comprises by weight: 100 parts of loam, 10 parts of biochar layer, 12 parts of animal excrement, 20 parts of plant ash, 20 parts of garden waste, 2 parts of urea;

[0043] A filter layer, which is arranged below the planting soil layer, the filter layer is as follows from left to right: a gravel filter layer 103, a porous concrete zeolite layer 104 and a cinder layer 106, the gravel filter layer 103, porous concrete zeolite The width ratio of layer 104 and cinder layer 106 is 1:3:1, and the thickness is 20cm;

[0044] Concrete anti-seepage layer 105, which is arranged below the filter l...

Embodiment 2

[0057] Embodiment 2 provides a wetland sewage purification system, comprising:

[0058] The first wetland tank 100, the first sedimentation tank 200, the second wetland tank 300, and the second sedimentation tank 400 are connected sequentially from top to bottom, wherein,

[0059] The first wetland pool 100 includes:

[0060] reed vegetation layer 101;

[0061] Planting soil layer 102, which comprises by weight: 150 parts of loam, 15 parts of biochar layer, 15 parts of animal excrement, 30 parts of plant ash, 30 parts of garden waste, 4 parts of urea;

[0062] A filter layer, which is arranged below the planting soil layer 102, the filter layer from left to right is: a gravel filter layer 103, a porous concrete zeolite layer 104 and a cinder layer 106, the gravel filter layer 103, porous concrete The width ratio of the zeolite layer 104 and the cinder layer 106 is 1:3:1, and the thickness is 30cm;

[0063] Concrete anti-seepage layer 105, which is arranged below the filter ...

Embodiment 3

[0076] Embodiment 3 provides a wetland sewage purification system, comprising:

[0077] The first wetland tank 100, the first sedimentation tank 200, the second wetland tank 300, and the second sedimentation tank 400 are connected sequentially from top to bottom, wherein,

[0078] The first wetland pool 100 includes:

[0079] reed vegetation layer 101;

[0080] Planting soil layer 102, which comprises by weight: 120 parts of loam, 12 parts of biochar layer, 13 parts of animal excrement, 25 parts of plant ash, 25 parts of garden waste, 3 parts of urea;

[0081] A filter layer, which is arranged below the planting soil layer, the filter layer is as follows from left to right: a gravel filter layer 103, a porous concrete zeolite layer 104 and a cinder layer 106, the gravel filter layer 103, porous concrete zeolite The width ratio of the layer 104 and the cinder layer 106 is 1:3:1, and the thickness is 25cm;

[0082] Concrete anti-seepage layer 105, which is arranged below the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com