Preparation method of functional porous graphene integrated electrode material and application of functional porous graphene integrated electrode material in vanadium battery

A technology of porous graphene and electrode materials, applied in fuel cells, regenerative fuel cells, battery electrodes, etc., can solve the problems of limiting vanadium battery performance and poor electrochemical reaction activity, achieve excellent electrical conductivity, and increase interface binding force , the effect of high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

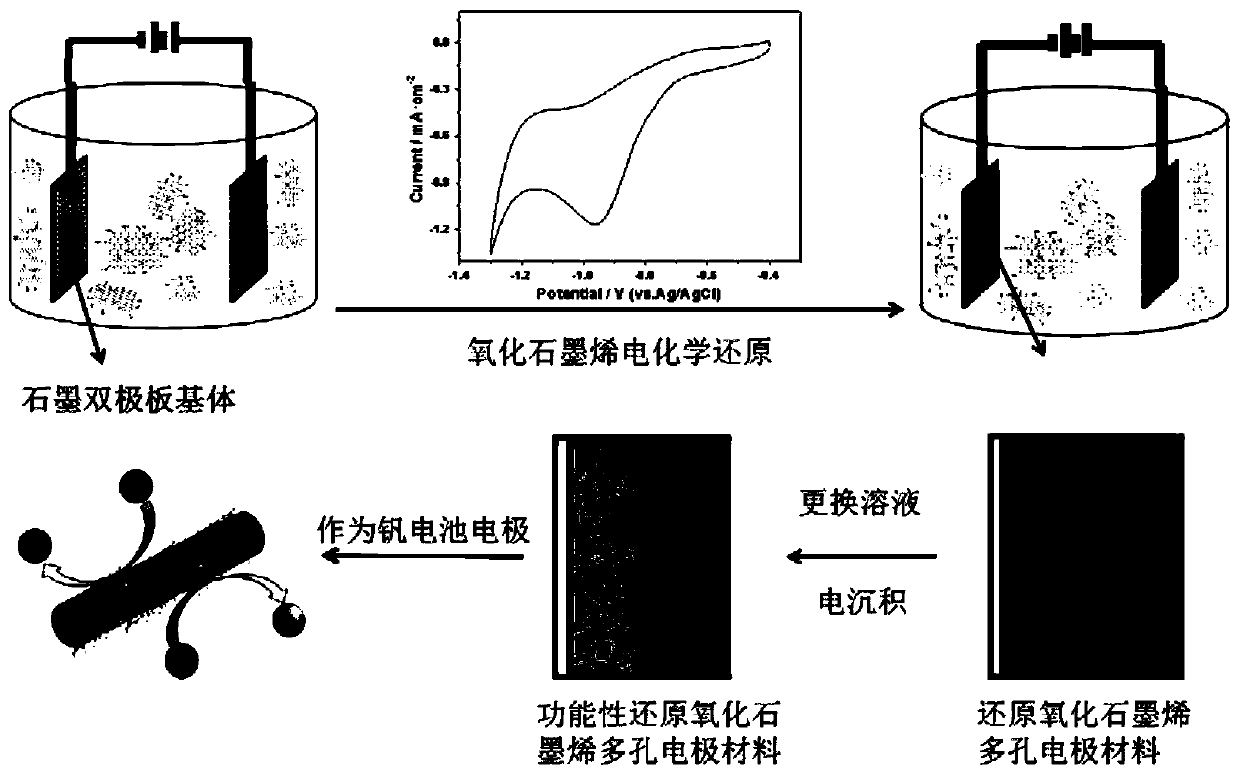

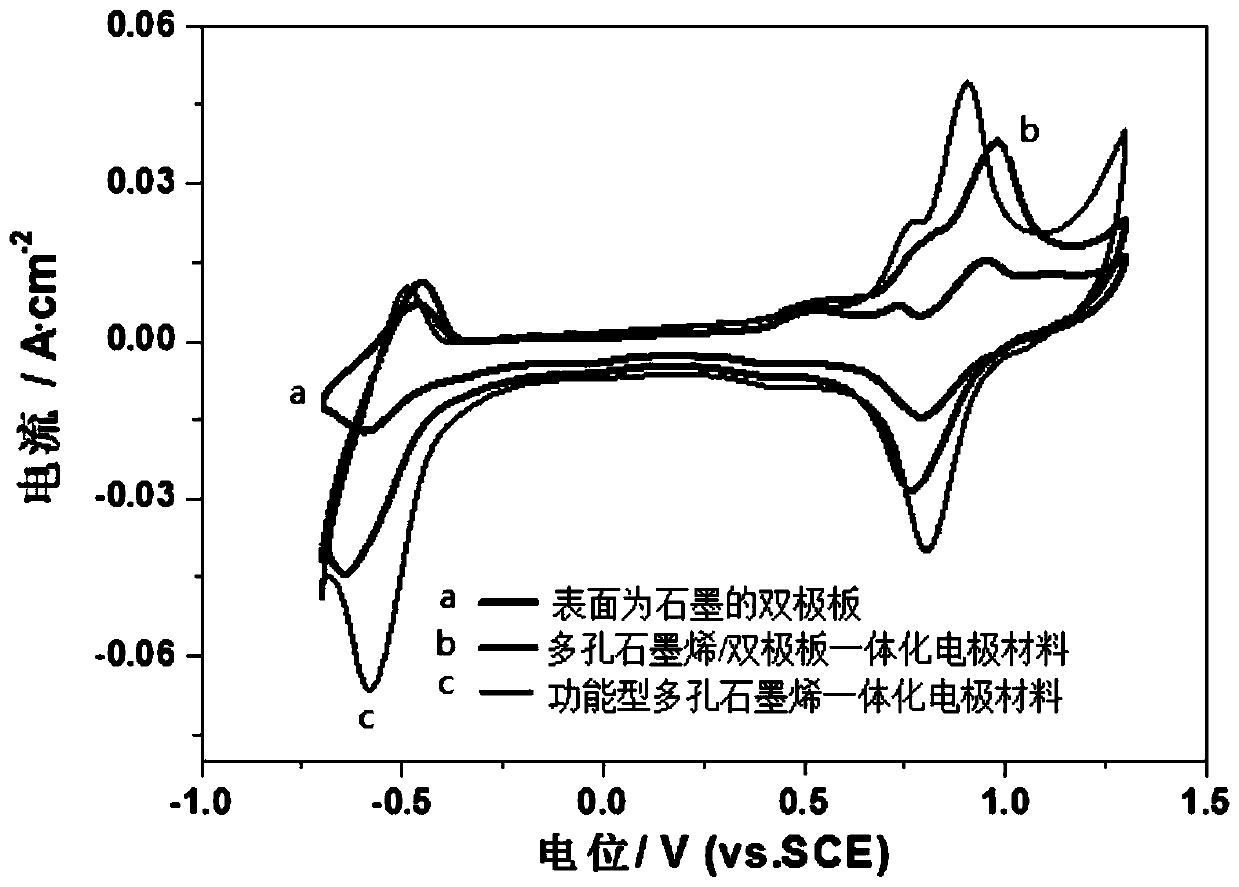

[0029] Example 1 Functional Porous Graphene Integrated Electrode Material

[0030] The preparation method comprises the following steps:

[0031] (1) Preparation of Porous Graphene / Flexible Graphite Plate Integrated Electrode Material

[0032] 1) Disperse graphene oxide in an aqueous solution, then add lithium perchlorate, mix well, and prepare a supporting electrolyte solution with a graphene oxide concentration of 5 mg / mL and a lithium perchlorate concentration of 0.15 mg / mL.

[0033] 2) The bipolar plate adopts a bipolar plate whose surface is graphite, and the surface conductivity is about 120S / cm.

[0034] 3) A bipolar plate (1cm×1cm) with a graphite surface was used as the working electrode, a saturated calomel electrode (SCE) connected with a saturated KCl salt bridge was used as the reference electrode, and a platinum sheet (2cm×2cm) was used as the auxiliary electrode. A three-electrode system uses an aqueous solution containing graphene oxide and lithium perchlorat...

Embodiment 2

[0041] Example 2 Functional Porous Graphene Integrated Electrode Material

[0042] The preparation method comprises the following steps:

[0043] (1) Preparation of Porous Graphene / Flexible Graphite Plate Integrated Electrode Material

[0044] 1) Disperse graphene oxide in an aqueous solution, then add lithium perchlorate, mix well, and prepare a supporting electrolyte solution with a graphene oxide concentration of 2 mg / mL and a lithium perchlorate concentration of 0.15 mg / mL.

[0045] 2) The bipolar plate adopts a bipolar plate whose surface is graphite, and the surface conductivity is about 120S / cm.

[0046] 3) A bipolar plate (1cm×1cm) with a graphite surface was used as the working electrode, a saturated calomel electrode (SCE) connected with a saturated KCl salt bridge was used as the reference electrode, and a platinum sheet (2cm×2cm) was used as the auxiliary electrode. A three-electrode system uses an aqueous solution containing graphene oxide and lithium perchlorat...

Embodiment 3

[0052] Example 3 Functional Porous Graphene Integrated Electrode Material

[0053] The preparation method comprises the following steps:

[0054] (1) Preparation of Porous Graphene / Flexible Graphite Plate Integrated Electrode Material

[0055] 1) Disperse graphene oxide in an aqueous solution, then add lithium perchlorate, mix well, and prepare a supporting electrolyte solution with a graphene oxide concentration of 8 mg / mL and a lithium perchlorate concentration of 0.15 mg / mL.

[0056] 2) The bipolar plate adopts a bipolar plate whose surface is graphite, and the surface conductivity is about 120S / cm.

[0057] 3) A bipolar plate (1cm×1cm) with a graphite surface was used as the working electrode, a saturated calomel electrode (SCE) connected with a saturated KCl salt bridge was used as the reference electrode, and a platinum sheet (2cm×2cm) was used as the auxiliary electrode. A three-electrode system uses an aqueous solution containing graphene oxide and lithium perchlorat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com