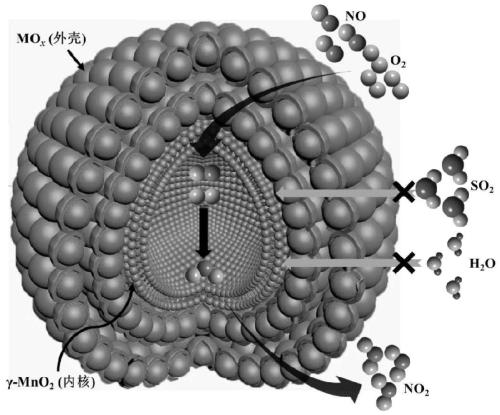

Hollow core-shell structure catalyst for catalytic oxidation of nitrogen oxide and preparation method of hollow core-shell structure catalyst

A technology of core-shell structure and nitrogen oxides, which is applied in the field of air pollution control, and achieves the effects of good stability, simple preparation method and prolonged service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

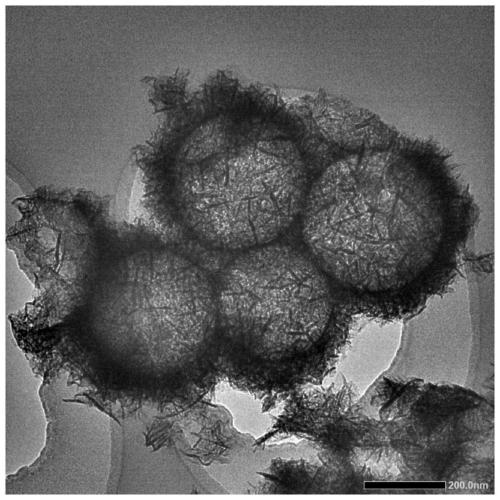

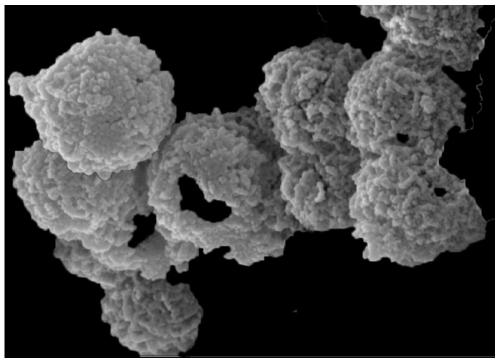

[0039] Example 1 Synthesis of hollow core-shell structure γ-MnO by hard template ~ hydrothermal method 2 @ZrO 2 catalyst

[0040] 0.5 g particles of 350 nm SiO 2 The powder is dispersed in a mixed solution of deionized water and ethanol for 15 minutes to obtain a white mixed solution, manganese nitrate is added to the white mixed solution, stirred at room temperature for 1 hour, and then the potassium permanganate solution (the quality of potassium permanganate is 0.2 g) was injected into the above mixed solution at a certain rate to obtain a suspension, and the suspension was stirred for 6 hours in a water bath at a temperature of 35°C, centrifuged, washed and dried to obtain a black solid, and the white solid was heated at a temperature of 300 Calcined at ℃ for 4h to obtain SiO 2 @γ-MnO 2 ; 2.2g zirconium oxynitrate and 0.2g cetyltrimethylammonium bromide are dissolved in water and ethanol mixed solution, then add the obtained SiO 2 @γ-MnO 2 After ultrasonic dispersion...

Embodiment 2

[0045] Example 2 Synthesis of hollow core-shell structure γ-MnO by hard template ~ hydrothermal method 2 @CeO 2 catalyst

[0046] The ammonium cerium nitrate in embodiment 1 is replaced by zirconium oxynitrate, cetyltrimethylammonium bromide is replaced by polyvinylpyrrolidone, the particle size of silicon dioxide is 250nm, manganese nitrate: potassium permanganate: cerium nitrate The mass ratio of ammonium: polyvinylpyrrolidone is 0.5: 0.36: 0.2: 2.5: 0.15, and the hollow core-shell structure γ-MnO is prepared according to the same method as in Example 1 2 @ZrO 2 sample.

[0047] According to powder X-ray diffraction pattern and transmission electron microscope analysis, the powder is mainly hollow core-shell structure γ-MnO 2 @CeO 2 catalyst. Investigated the change of the conversion rate of this catalyst action nitric oxide with temperature and anti-sulfur performance ( Image 6 ), the results show that the catalyst has excellent water and sulfur resistance and stabi...

Embodiment 3

[0048] Example 3 Synthesis of hollow core-shell structure γ-MnO by hard template ~ hydrothermal method 2 @La 2 o 3 catalyst

[0049] Lanthanum nitrate in Example 1 is replaced by zirconyl nitrate, polyethylene glycol is replaced by polyvinylpyrrolidone, the particle size of silicon dioxide is 450nm, silicon dioxide: manganese nitrate: potassium permanganate: lanthanum nitrate: polyethylene The mass ratio of diol is 0.75:0.36:0.2:2.8:0.25, and the hollow core-shell structure γ-MnO is prepared according to the same method as in Example 1 2 @La 2 o 3 sample.

[0050] According to powder X-ray diffraction pattern and transmission electron microscope analysis, the powder is mainly hollow core-shell structure γ-MnO 2 @La 2 o 3 catalyst. The same method as in Example 1 was used to repeatedly measure the change of the conversion rate of nitric oxide under the action of the catalyst as a function of temperature, and the results showed that the catalyst had excellent water and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com