A high-strength and high-weather resistance two-component polyurethane structural adhesive and its preparation method

A two-component polyurethane, weather resistance technology, applied in polyurea/polyurethane adhesives, chemical instruments and methods, adhesives, etc., can solve the problems of low tensile strength and elongation at break, poor weather resistance, aging, etc. Achieve the effect of improving flexibility, ensuring stable quality, good weather resistance and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] On the other hand, the present invention also provides a method for preparing a high-strength and high-weather resistance two-component polyurethane structural adhesive, comprising the following steps:

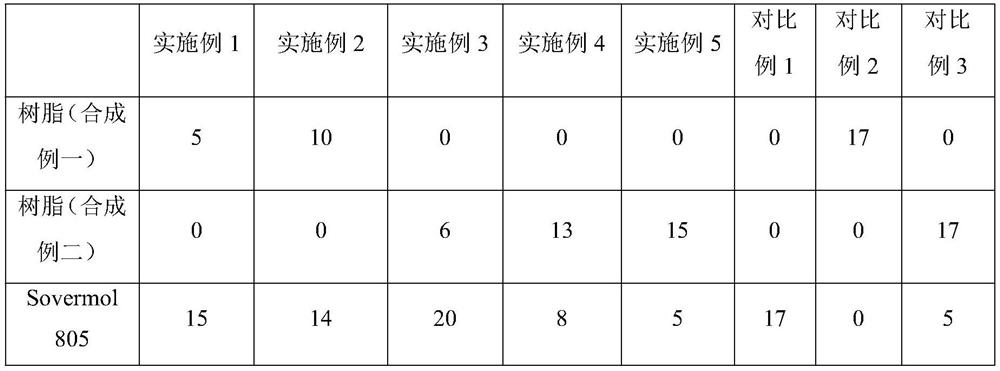

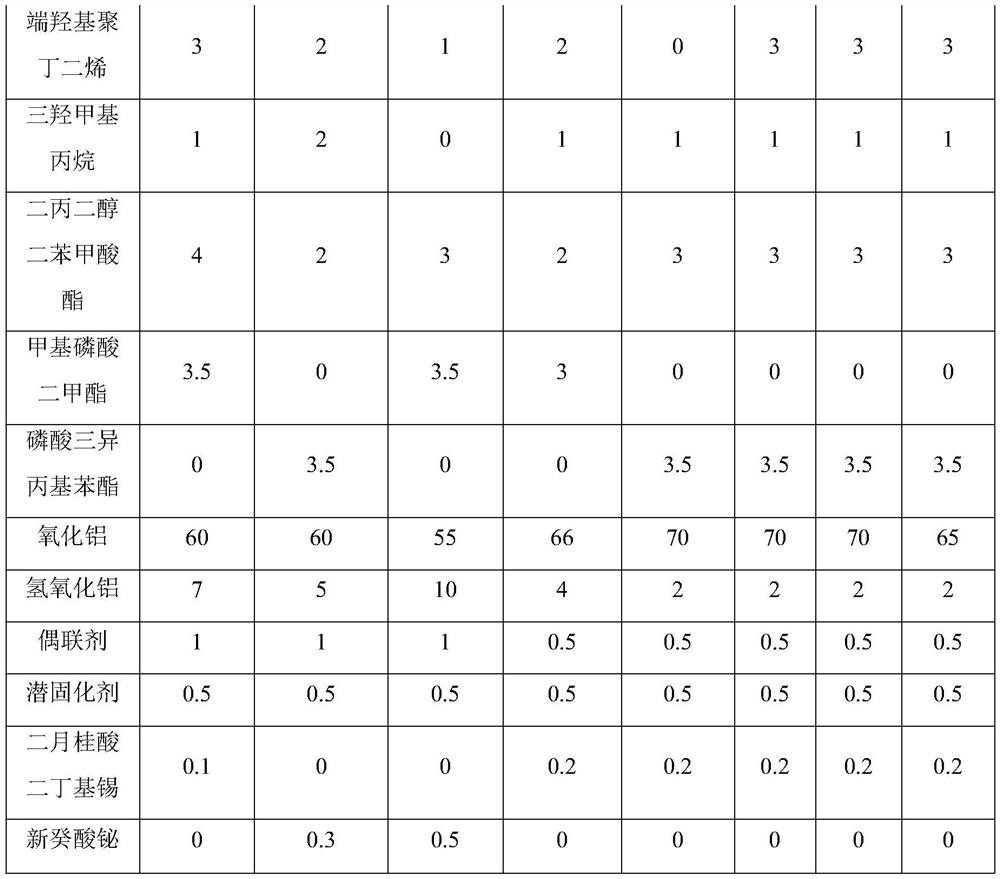

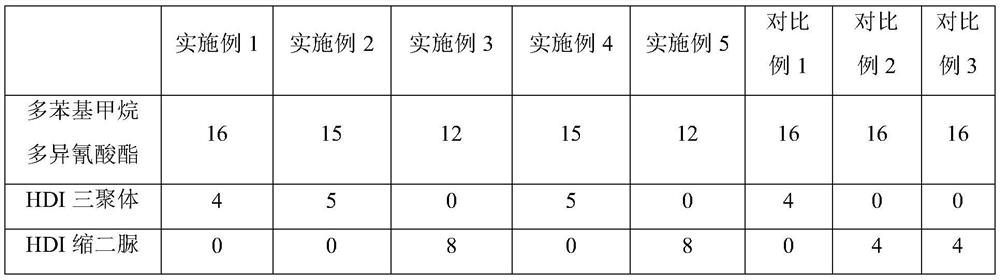

[0067] Step S1, preparation of component A: add linear macromolecular hydroxymethacrylate resin, hydroxyl-terminated polyol, tackifying resin, environmental protection plasticizer, flame retardant plasticizer Stir for 10-15 minutes at rpm to mix the liquid raw materials evenly; then add thermally conductive fillers and flame-retardant fillers, and stir for 10 minutes at a speed of 20-30 rpm. When the powder completely forms a paste with the liquid raw materials, increase the Stir at a speed of 800-1100 rpm, and heat to 110-120°C at the same time. Under a vacuum degree of ≤-0.095MPa, stir and dehydrate for 2-3 hours. After the moisture content is tested to be less than 500ppm, cool down to below 60°C; Curing agent, coupling agent, catalyst, stirred for 20-30 minutes, dis...

Synthetic example 1

[0075] This synthesis example provides a kind of linear macromolecular hydroxymethacrylate resin, and its preparation raw material comprises: dipropylene glycol dibenzoate: 20 parts, methyl methacrylate: 38 parts, n-butyl acrylate Esters: 14 parts, mercaptoethanol: 2 parts, styrene: 10 parts, lauryl methacrylate: 10 parts, 2-hydroxyethyl acrylate: 5 parts, azobisbutyronitrile: 0.5 parts, 2,6- Di-tert-butyl-p-cresol: 0.5 parts.

[0076] Above-mentioned linear macromolecule hydroxymethacrylate resin synthesis method comprises:

[0077]Add the above amount of dipropylene glycol dibenzoate, methyl methacrylate, n-butyl acrylate, and mercaptoethanol into the reaction kettle, open the condensing device and stirring device, feed nitrogen, heat to 75°C, and add 0.2 parts of Azobisbutyronitrile, stirred and dissolved, and reacted at 75°C for 1h, added dropwise a mixed solution composed of styrene, lauryl methacrylate, and 0.2 parts of azobisbutyronitrile, and the dropwise addition was...

Synthetic example 2

[0079] This synthesis example provides a kind of linear macromolecular hydroxymethacrylate resin, and its preparation raw material comprises: dipropylene glycol dibenzoate: 15 parts, methyl acrylate: 40 parts, ethyl acrylate: 8 parts by weight , mercaptoethanol: 1 part, styrene: 16 parts, lauryl methacrylate: 10 parts, 2-hydroxyethyl methacrylate: 8 parts, azobisbutyronitrile: 1 part, 2,6-di-tert Butyl p-cresol: 1 part.

[0080] Above-mentioned linear macromolecule hydroxymethacrylate resin synthesis method comprises:

[0081] Add dipropylene glycol dibenzoate, methyl acrylate, ethyl acrylate, and mercaptoethanol in the above proportions into the reaction kettle, open the condensing device and stirring device, feed nitrogen, heat to 75°C, and add 0.4 parts of azobis Butyronitrile, stir to dissolve, and react at 75°C for 1h, add dropwise a mixed solution composed of styrene, lauryl methacrylate, and 0.4 parts of azobisbutyronitrile, complete the dropwise addition within 1h, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com