PP/PE composite material with high fluidity, high impact resistance and low emission based on electrostatic self-assembly and preparation method of PP/PE composite material

An electrostatic self-assembly, composite material technology, applied in the field of polymer materials, can solve problems such as unfavorable polymer melt processing flow, and achieve the effects of low emission, low processing energy consumption, and high environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

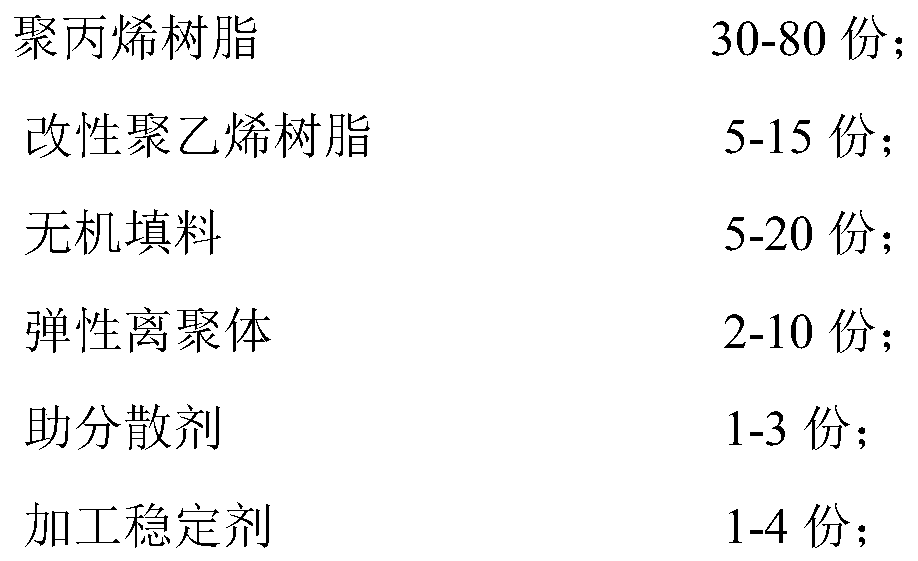

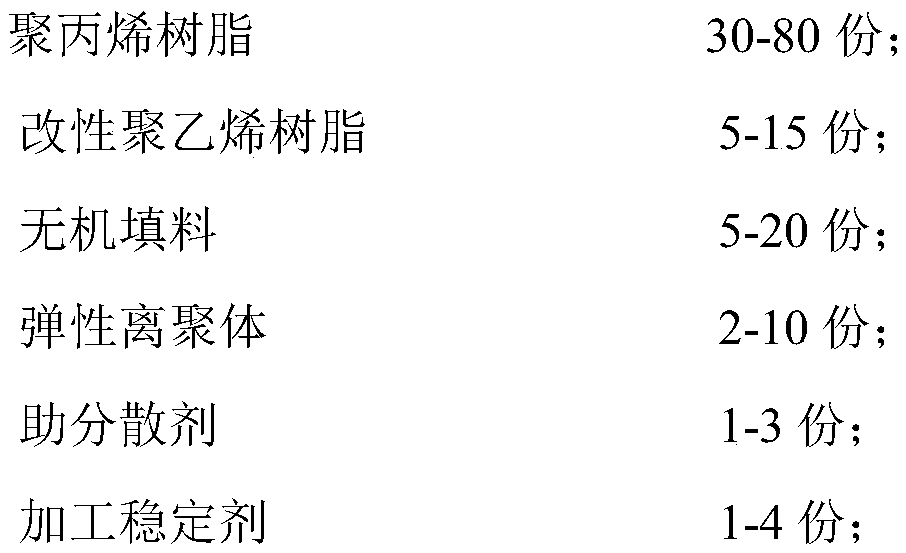

Method used

Image

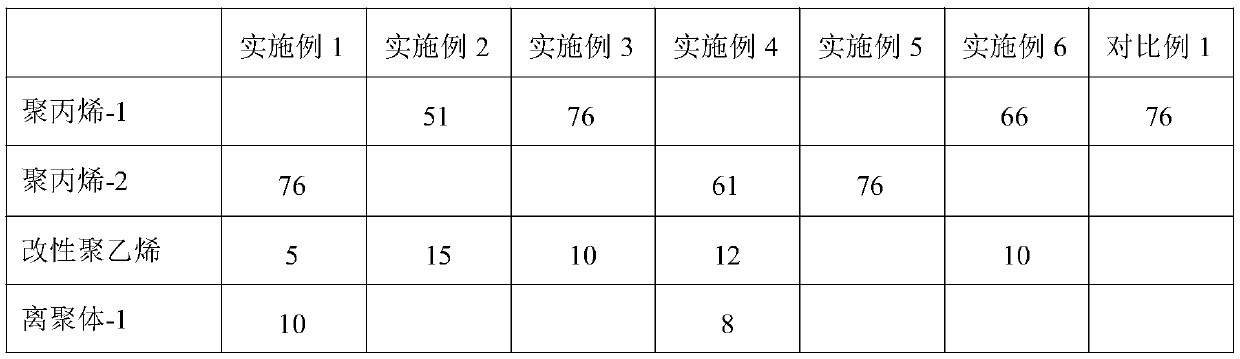

Examples

Embodiment 1

[0043] According to the data of Example 1 shown in Table 1, the polypropylene resin, inorganic filler, elastic ionomer, auxiliary dispersant, and processing stabilizer were weighed out in proportion, and mixed uniformly to obtain mixed raw materials.

[0044] Place the dried mixed raw materials in the main feed bin of a twin-screw extruder that is tightly meshed and rotates in the same direction, and add the feed screw to the barrel of the extruder; place the modified polyethylene resin in the In the side feeding bin of the extruder screw, it is added to the extruder barrel through the feeding screw. The diameter of the screw extruder used is 40mm, the length-to-diameter ratio L / D is 56, and the temperature of each zone of the main barrel from the feeding port to the head outlet is set to: 100℃, 170℃, 180℃, 190℃, 180℃ , 180℃, 190℃, 190℃, 190℃, the main engine speed is 250 rpm, after melt extrusion, granulation, drying treatment and other processes, the high flow, high impact resi...

Embodiment 2

[0046] According to the data of Example 2 shown in Table 1, the polypropylene resin, inorganic filler, elastic ionomer, co-dispersant, and processing stabilizer were weighed out in proportion, and mixed uniformly to obtain mixed raw materials.

[0047] Place the dried mixed raw materials in the main feed bin of a twin-screw extruder that is tightly meshed and rotates in the same direction, and add the feed screw to the barrel of the extruder; place the modified polyethylene resin in the In the side feeding bin of the extruder screw, it is added to the extruder barrel through the feeding screw. The diameter of the screw extruder used is 40mm, the length-to-diameter ratio L / D is 56, and the temperature of each zone of the main barrel from the feeding port to the head outlet is set to: 100℃, 170℃, 180℃, 190℃, 180℃ , 180℃, 190℃, 190℃, 190℃, the main engine speed is 250 rpm, after melt extrusion, granulation, drying treatment and other processes, the high flow, high impact resistance,...

Embodiment 3

[0052] According to the data of Example 3 shown in Table 1, the polypropylene resin, inorganic filler, elastic ionomer, auxiliary dispersant, and processing stabilizer were weighed out in proportion, and mixed uniformly to obtain mixed raw materials.

[0053] Place the dried mixed raw materials in the main feed bin of a twin-screw extruder that is tightly meshed and rotates in the same direction, and add the feed screw to the barrel of the extruder; place the modified polyethylene resin in the In the side feeding bin of the extruder screw, it is added to the extruder barrel through the feeding screw. The diameter of the screw extruder used is 40mm, the length-to-diameter ratio L / D is 56, and the temperature of each zone of the main barrel from the feeding port to the head outlet is set to: 100℃, 170℃, 180℃, 190℃, 180℃ , 180℃, 190℃, 190℃, 190℃, the main engine speed is 250 rpm, after melt extrusion, granulation, drying treatment and other processes, the high flow, high impact resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com