Fermentation medium for producing demethylated aureomycin

A technology of demethylaureomycin and fermentation medium, which is applied in the direction of microorganism-based methods, fermentation, and growth stimulation by adding compounds, can solve the problems of high price, difficult application of medium, and increase of fermentation operation cost, etc., and achieves The effect of increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0015] a Preparation of fermentation medium: Weigh 28g of cornstarch, 0.2g of molasses, 14g of high-temperature soybean powder, 10g of corn oil, 6g of corn steep liquor, 2.2g of calcium carbonate, 0.8g of calcium chloride, 0.48g of ammonium sulfate, and 0.06 potassium dihydrogen phosphate g, L-lysine salt 2g, a-amylase 0.002g. First gelatinize the starch, add amylase, cool for later use, then dissolve the other ingredients in purified water, and finally combine the two parts of the liquid, set the volume to 400ml, adjust the pH to 5.5, and evenly distribute it into ten 250ml shaker flasks sterilized at 121°C for 30 minutes, and cooled to room temperature for use.

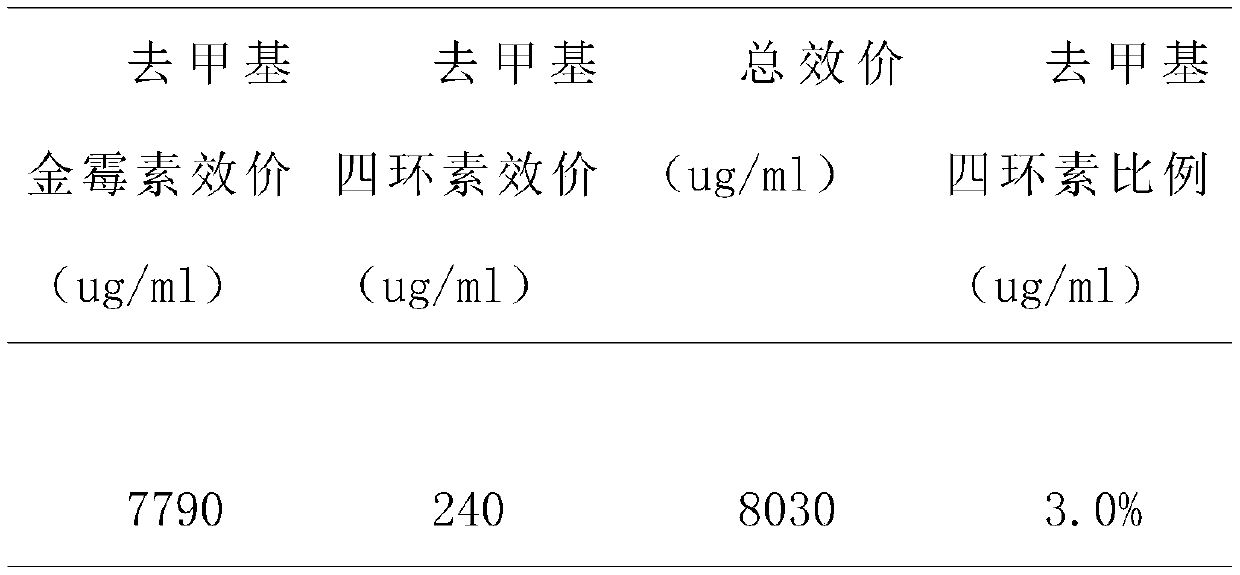

[0016] b Take 2ml of mature seed culture solution and insert it into ten 250ml shake flasks equipped with 40ml of fermentation medium, culture temperature is 28 degrees, shaker speed is 200rpm, culture period is 168 hours. After the fermentation is terminated, use high pressure liquid chromatography to measure the ...

example 2

[0019] a Preparation of fermentation medium: Weigh 28g of cornstarch, 0.4g of molasses, 14g of high-temperature soybean powder, 10g of corn oil, 6g of corn steep liquor, 2.2g of calcium carbonate, 1.2g of calcium chloride, 0.48g of ammonium sulfate, and 0.06 potassium dihydrogen phosphate g, L-lysine salt 2g, a-amylase 0.002g. First gelatinize the starch, add amylase, cool for later use, then dissolve the other ingredients in purified water, and finally combine the two parts of the liquid, set the volume to 400ml, adjust the pH to 5.5, and evenly distribute it into ten 250ml shaker flasks sterilized at 121°C for 30 minutes, and cooled to room temperature for use.

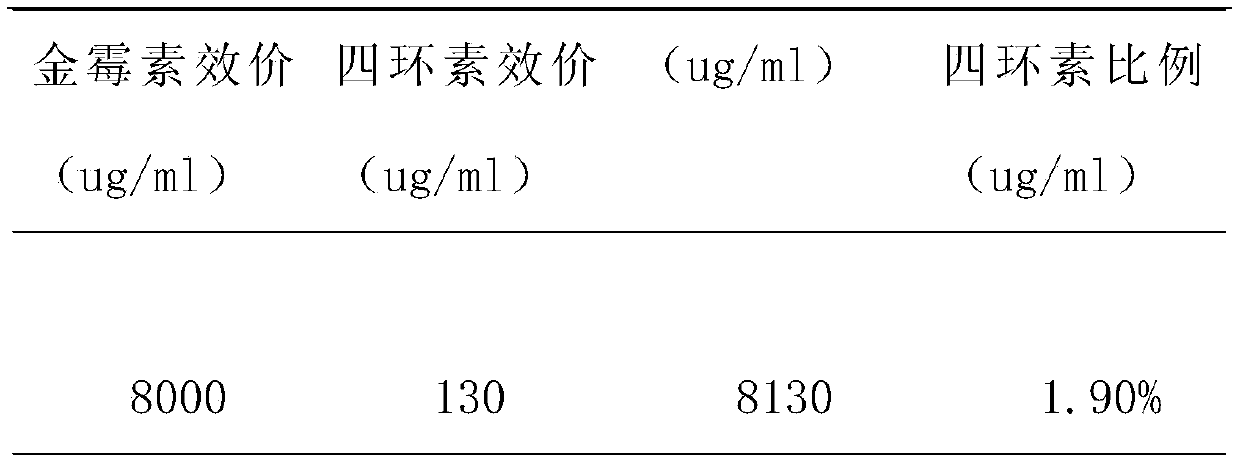

[0020] b Take 2ml of mature seed culture solution and insert it into ten 250ml shake flasks equipped with 40ml of fermentation medium, culture temperature is 28 degrees, shaker speed is 200rpm, culture period is 168 hours. After the fermentation is terminated, use high pressure liquid chromatography to measure the ...

example 3

[0024] a Preparation of fermentation medium: Weigh 28g of corn starch, 0.6g of molasses, 14g of high-temperature soybean powder, 10g of corn oil, 6g of corn steep liquor, 2.2g of calcium carbonate, 1.6g of calcium chloride, 0.48g of ammonium sulfate, and 0.06 potassium dihydrogen phosphate g, L-lysine salt 2g, a-amylase 0.002g. First gelatinize the starch, add amylase, cool for later use, then dissolve the other ingredients in purified water, and finally combine the two parts of the liquid, set the volume to 400ml, adjust the pH to 5.5, and evenly distribute it into ten 250ml shaker flasks sterilized at 121°C for 30 minutes, and cooled to room temperature for use.

[0025] b Take 2ml of mature seed culture solution and insert it into ten 250ml shake flasks equipped with 40ml of fermentation medium, culture temperature is 28 degrees, shaker speed is 200rpm, culture period is 168 hours. After the fermentation is terminated, use high pressure liquid chromatography to measure the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com