Method for physicochemical and biochemical combined treatment of coking wastewater

A coking wastewater and combined treatment technology, which is applied in the fields of chemical instruments and methods, biological water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of great harm to the human body, lower biochemical treatment efficiency, and "difficult discharge standards for coking wastewater treatment process" etc. to achieve high COD degradation efficiency, reduce ozone treatment costs, and reduce the generation of concentrated water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

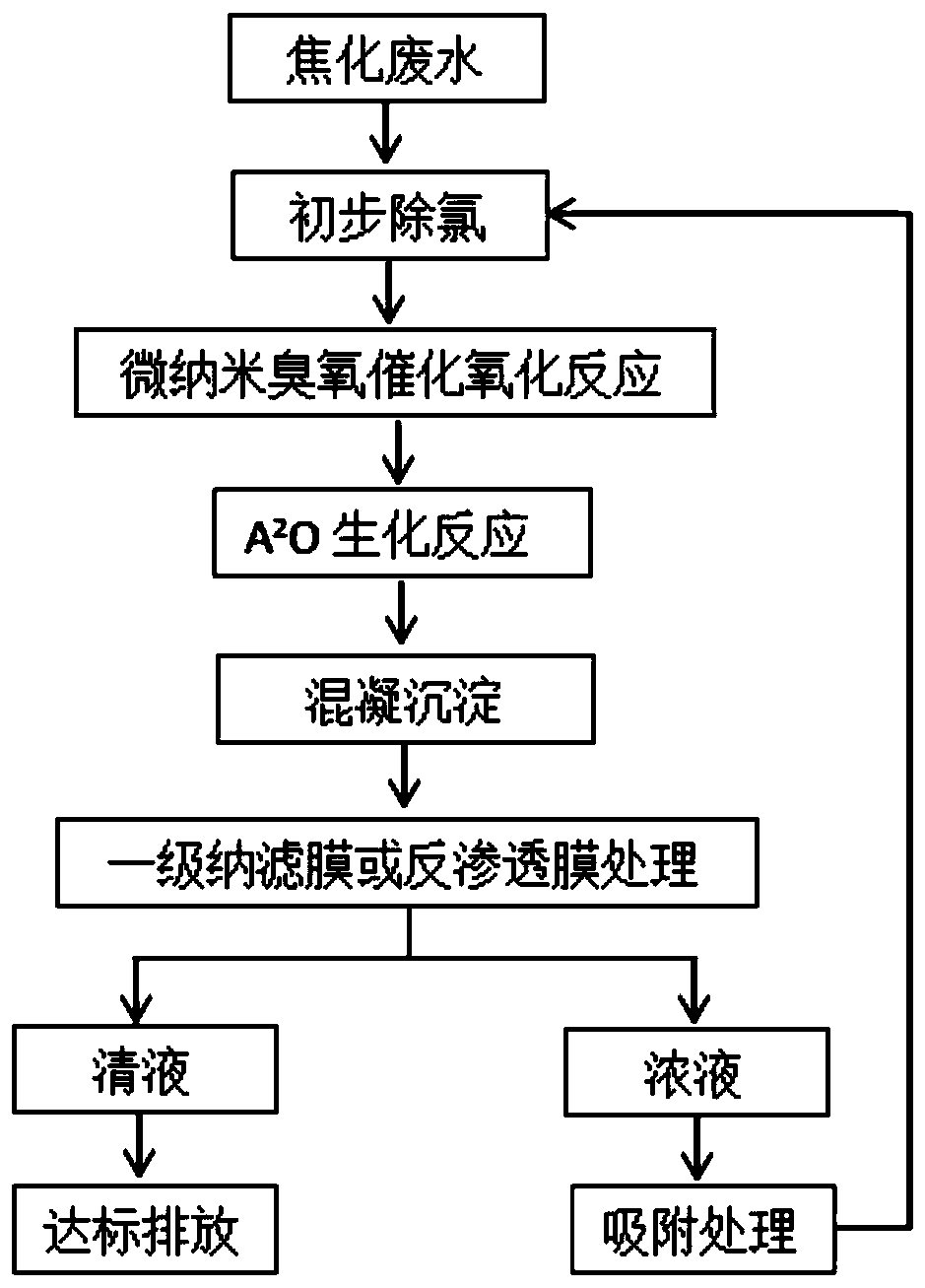

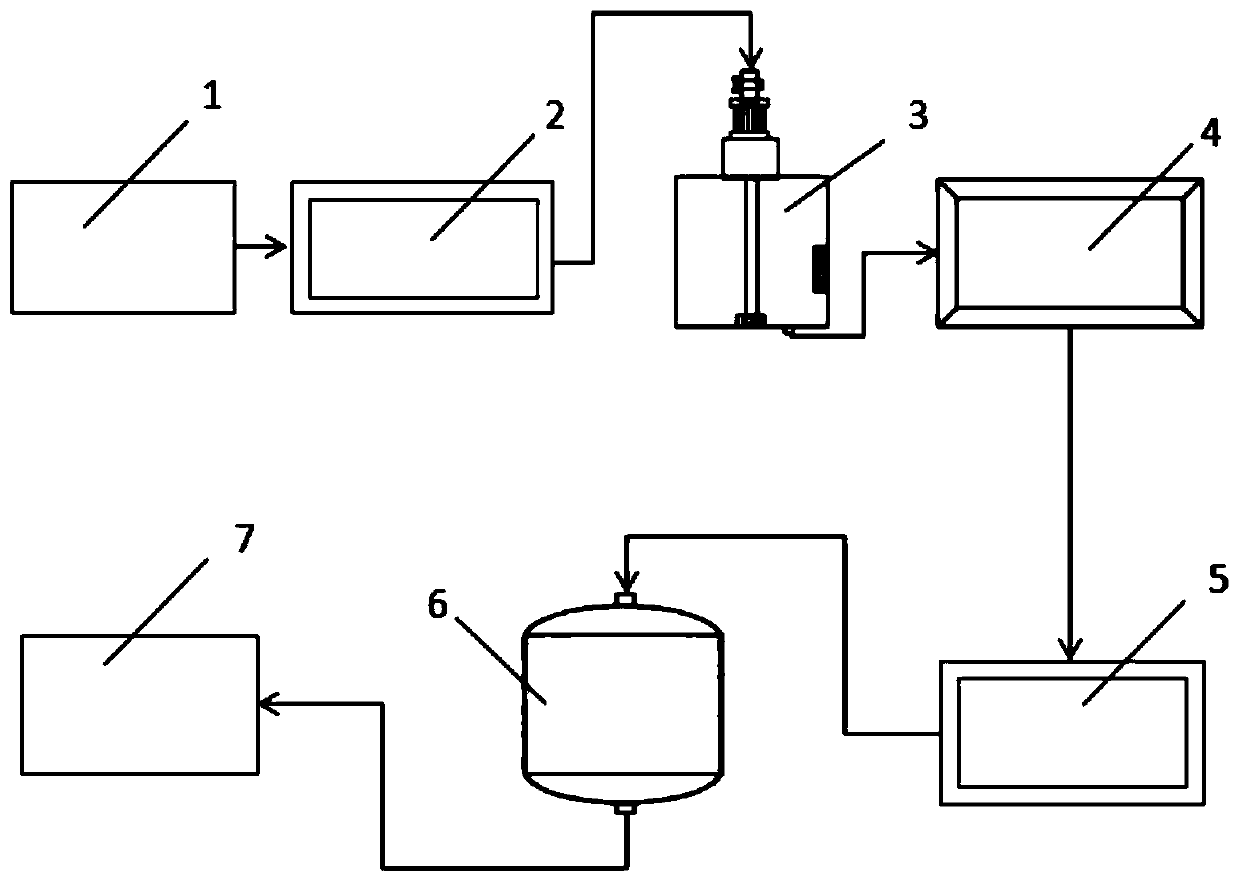

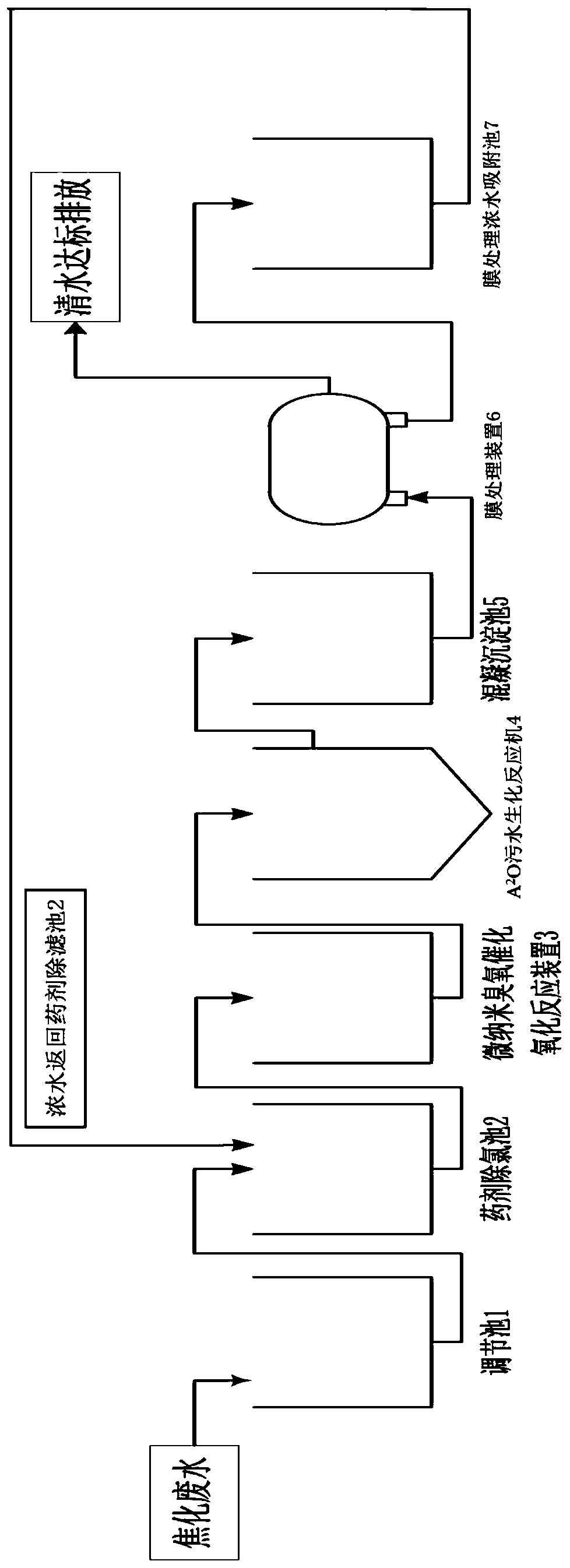

[0057] A physical, chemical and biochemical combined treatment method for coking wastewater, the main indicators of coking wastewater influent: pH is 9.4, COD concentration is 2736mg / L, ammonia nitrogen concentration is 155mg / L, total phosphorus concentration is 2.57mg / L, the treatment method is as follows figure 1 As shown, the processing system as figure 2 , image 3 As shown, it specifically includes the following steps:

[0058] (1) The coking wastewater enters the chemical dechlorination pool 2 after adjusting the pH to 10 through the regulating pool 1, and calcium oxide and sodium metaaluminate are added in the chemical dechlorination pool 2, and the n(Ca):n(Al):n( Cl) molar ratio is 15:4.5:1, and stirring 1h at 400r / min speed, after filtering to remove sediment, obtain the coking waste water of primary dechlorination;

[0059] This process makes calcium oxide and sodium metaaluminate react with chloride ions in coking wastewater to form calcium aluminum chloride compou...

Embodiment 2

[0078] A physical, chemical and biochemical combined treatment method for coking wastewater, the main indicators of coking wastewater influent: pH is 9.4, COD concentration is 2736mg / L, ammonia nitrogen concentration is 155mg / L, total phosphorus concentration is 2.57mg / L, the treatment method is as follows figure 1 As shown, the processing system as figure 2 , image 3 As shown, it specifically includes the following steps:

[0079] (1) The coking wastewater enters the chemical dechlorination pool 2 after adjusting the pH to 10 through the regulating pool 1, and calcium oxide and sodium metaaluminate are added in the chemical dechlorination pool 2, and the n(Ca):n(Al):n( Cl) molar ratio is 15:4.5:1, and stirring 1h at 400r / min speed, after filtering to remove sediment, obtain the coking waste water of primary dechlorination;

[0080] This process makes calcium oxide and sodium metaaluminate react with chloride ions in coking wastewater to form calcium aluminum chloride comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com