Modified fluorosilane composite sol and preparation method thereof, coating containing the modified fluorosilane composite sol, preparation method and application thereof

A composite sol and fluorosilane technology, applied in polyether coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of antibacterial and antiviral active components loss, insufficient antibacterial and antiviral ability, single function, etc. Virus adhesion, excellent antiviral and antibacterial properties, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method of preparing the modified fluorosilane composite sol, and the specific embodiments include:

[0026] 1. Based on mass parts, 2 parts of the copperide of 2 parts having a average particle diameter of 200 nm and a titanium dioxide having an average particle diameter of 100 nm are mixed in a ball mill under a ball mill, and a copper phosphate is doped. Modified titanium dioxide, by spherical milling, causes copper phosphate to be doped in titanium dioxide to obtain a modified titanium dioxide having a smaller particle size, and the average particle diameter obtained in the modified titanium dioxide obtained in this example is 50 nm;

[0027] 2. The modified titanium dioxide, 20 parts of methacrylate, and 15 parts of vinyl trimethoxysilane and 1 part initiator BPO were dispersed in 40 parts of ethanol at 60 ° C for 4 h in 40 ° C. The entire reaction process was stirred, and the precipitate in the mixed solution was collected, and the precipitate was dried to give a m...

Embodiment 2

[0035] The steps of this embodiment are substantially identical in the first embodiment, and the difference is that the three parts of the average particle diameter of 500 nm of titanium dioxide and 30 parts of the average particle diameter of 200 nm are mixed in the weight parts of the weight parts. The ball milling speed is 1500r / min, the ball milling time is 8 h, the prepared modified titanium dioxide has an average particle diameter of 200 nm; in step 2, 30 parts of methacrylate, 20 parts of vinyl triethoxysilane And 3 initiate BPO were dispersed in 50 parts of isopropanol, and the reaction temperature was 70 ° C, and the reaction time was 6 h.

[0036] According to the weight of the weight, 15 parts of modified fluorosilane composite sol, 30 parts of silicon ether resin and 50 parts of ethyl acetate were taken, and mixed uniformly, obtained coating.

[0037] During the actual use, the coating is applied to the glass substrate, cured at 80 ° C for 1 hour, and a coating is fo...

Embodiment 3

[0042] The steps of this embodiment are substantially the same as in the first embodiment, and the difference is that the cobalt dioxide and 35 parts of the average particle diameter of 150 nm are mixed with 35 parts of the average particle diameter of 150 nm in step 1. The ball milling speed is 1350 r / min, the ball milling time is 7 h, the prepared modified titanium dioxide is 140 nm; in step 2, 25 parts of methacrylate, 18 parts of vinyl triethoxysilane And 2 primary BPO was dispersed in 55 parts of ethylene glycol, and the reaction temperature was 65 ° C, and the reaction time was 8 h.

[0043] According to the mass parts, 12 modified fluorosilane composite sol, 25 parts of unsaturated polyester and 45 parts of diethyl ether were mixed, and mixed uniform and obtained coating.

[0044] During the actual use, the coating is applied to the ceramic substrate, cured at 90 ° C for 1 hour, and a coating is formed on the ceramic substrate.

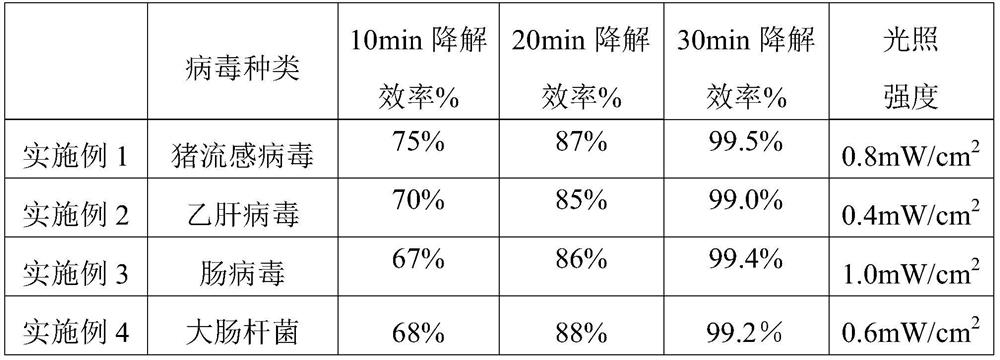

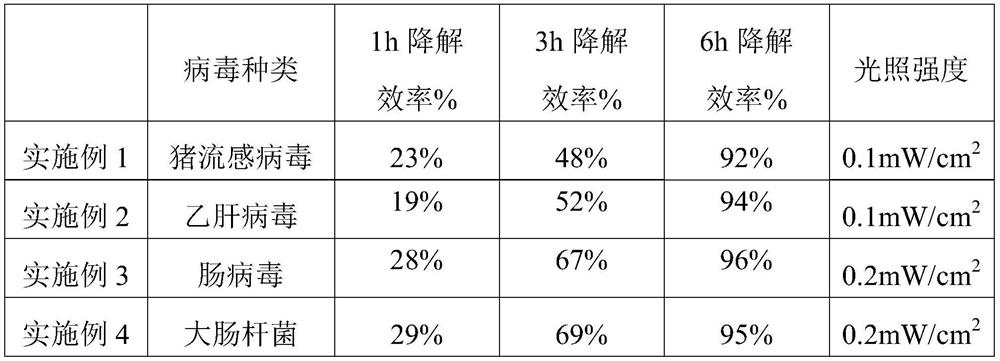

[0045] The coating prepared by the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com