Raw material for processing non-woven fabric polishing wheel and manufacturing method of non-woven fabric polishing wheel

A manufacturing method and technology of non-woven fabrics, applied in the direction of manufacturing tools, textiles, papermaking, metal processing equipment, etc., can solve problems such as poor softness, low production capacity, and poor uniformity, so as to improve uniformity, reliability and Quality, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

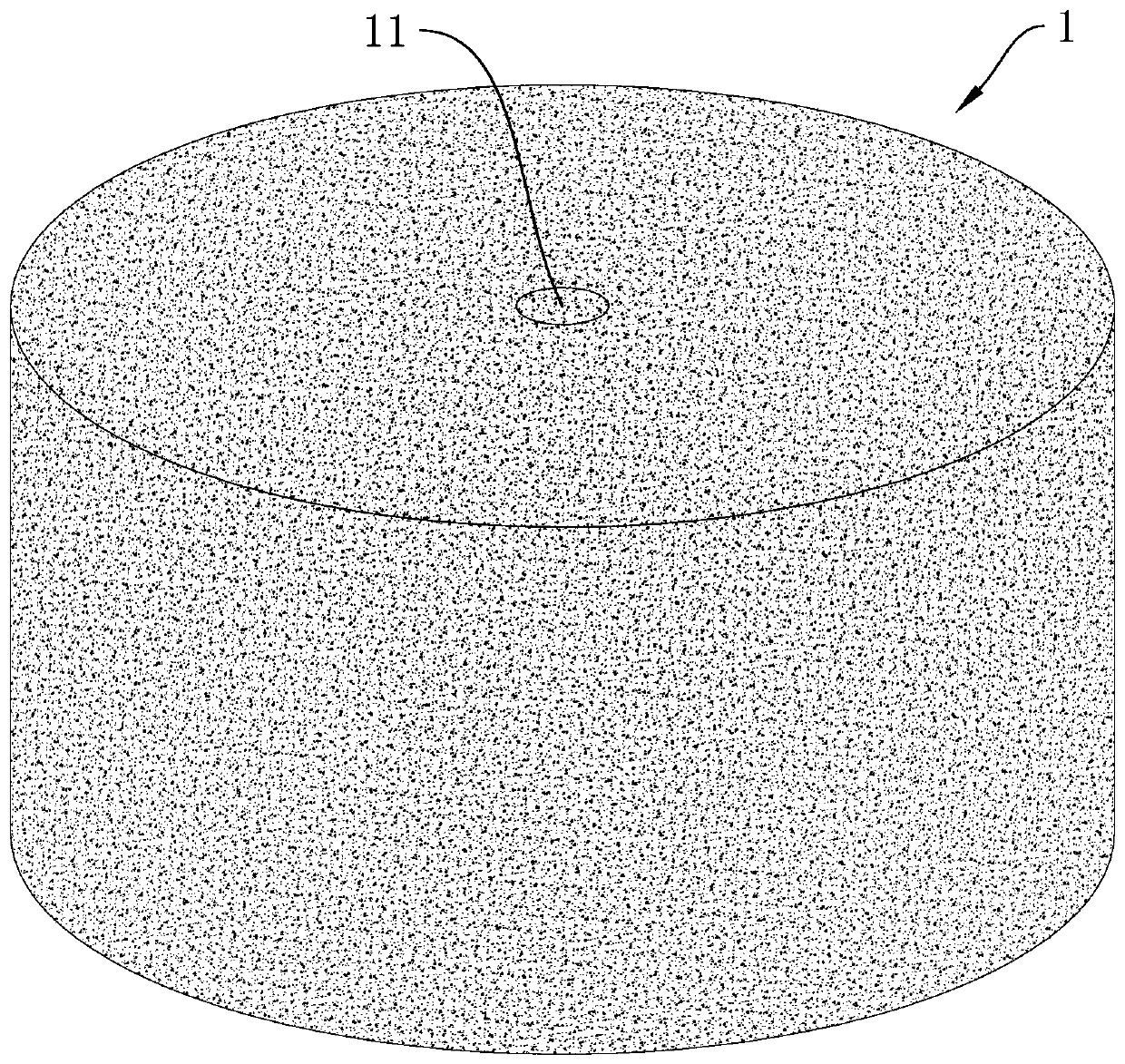

[0015] Such as figure 1 Shown, a kind of raw material of processing nonwoven polishing wheel of the present invention and the manufacture method of nonwoven polishing wheel, are 30~40% epoxy resin glue, 7.5~13.5% curing agent, 1~40% by weight percentage 5% accelerator, 40-55% abrasive, 0.5-1% toner, 5-10% solvent. By using such raw materials, it is helpful to improve the reliability and quality of the non-woven polishing wheel, and it is convenient to quickly polish the clay pot in place, and it can improve the uniformity, gloss, softness and feel of the clay pot polishing, so that it can be convenient Improve the quality of clay pots.

[0016] The curing agent is polyamide polyamine, aliphatic polyamine, aromatic polyamine, acid anhydride, imidazole compound or boron trifluoride complex.

[0017] The accelerator is 2,2'-dithiodibenzothiazole.

[0018] The abrasive is calcium carbonate, corundum, magnesium oxide, magnesium hydroxide, magnesium carbonate or calcium silicate....

Embodiment 2

[0022] A kind of manufacture method of processing non-woven polishing wheel with the raw material described in embodiment one, comprises the steps:

[0023] (1) prepare the raw material described in embodiment one and non-woven fabric fiber cotton;

[0024] (2) Mix the raw materials evenly and apply them evenly on the non-woven fiber cotton by rolling, then laminate them in the shaping mold according to the required thickness, and then place them in an oven for curing and forming;

[0025] (3) Take the non-woven fabric fiber cotton block out of the shaping mold, then dry it, then punch out the required size specifications in the punch press, and then enter the oven for curing;

[0026] (4) Put the dried semi-finished product into the dipping tank, soak it with solvent and brightener, take it out to remove the solvent, place the semi-finished product in a vacuum drying oven, dry and recover the solvent, and dry it after drying. A finished non-woven polishing wheel is obtained....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com