Solid chlorine dioxide sustained-release agent

A chlorine dioxide and slow-release technology, applied in biocides, disinfectants, gas treatment and other directions, can solve the problems of difficult precise control, unsuccessful, long induction period, etc., to ensure no corrosion and low material loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

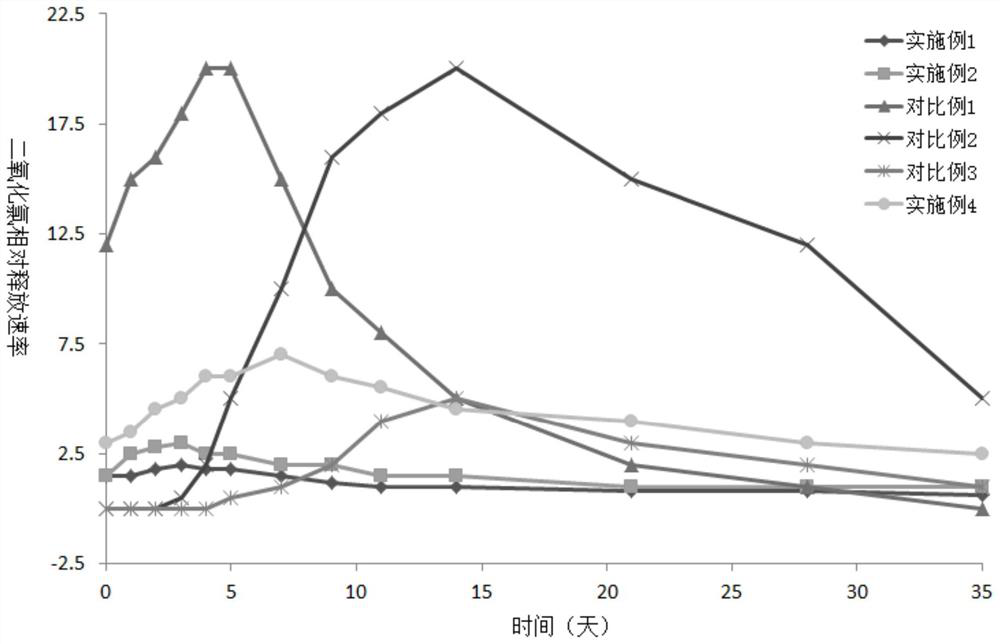

Examples

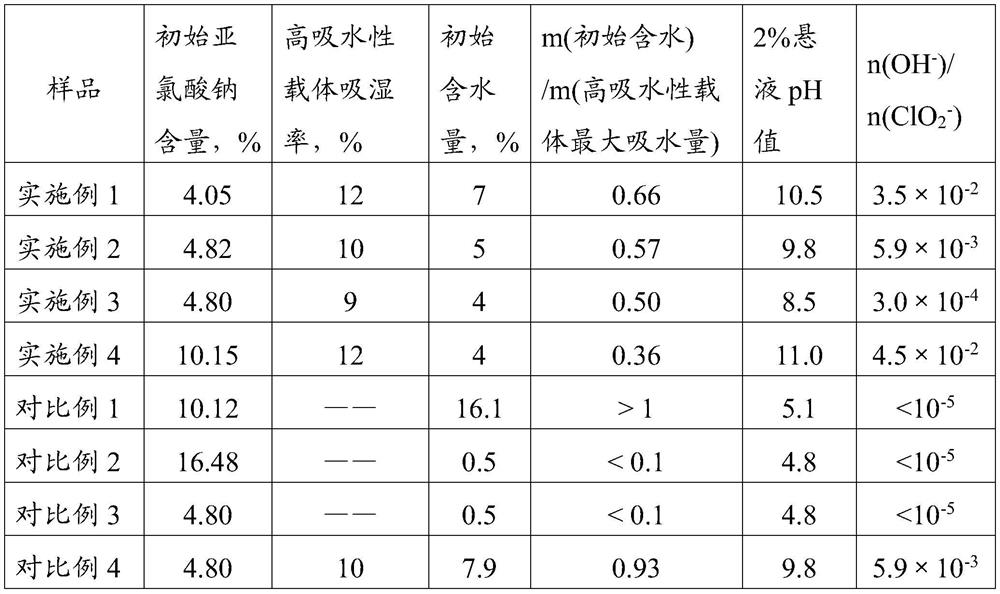

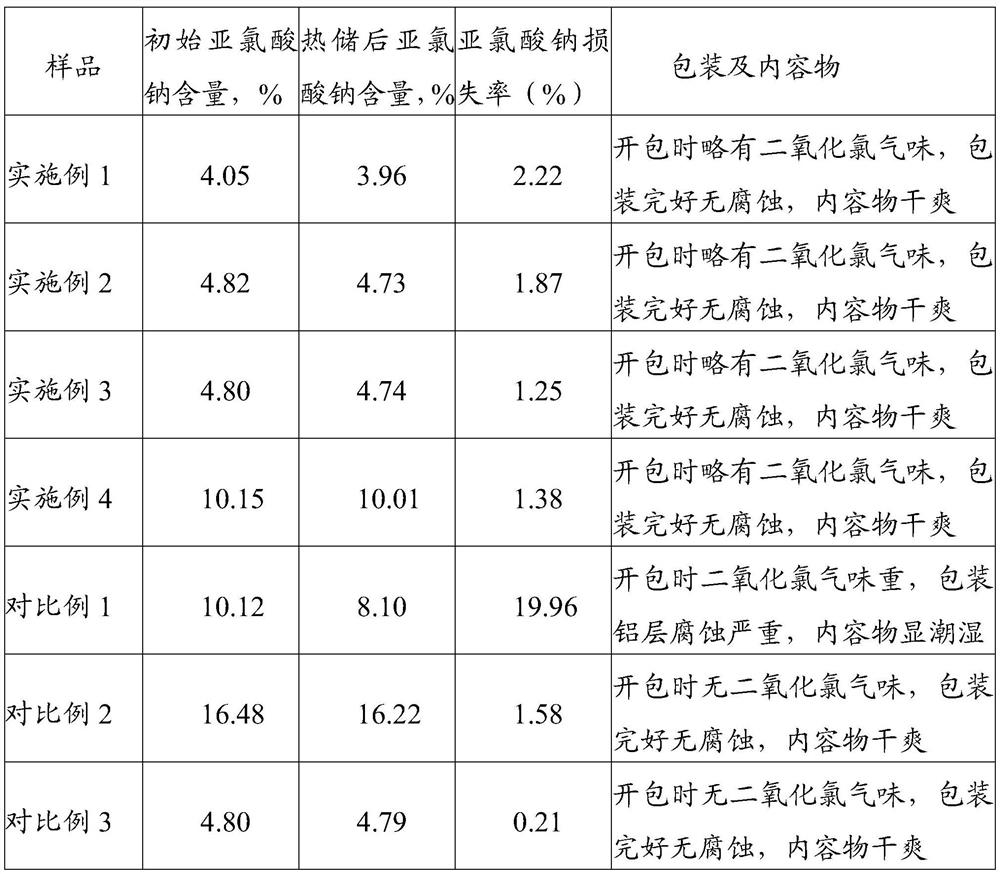

Embodiment 1

[0051] A solid chlorine dioxide sustained-release agent, which consists of the following components in mass percentage: 5% chlorite, 87.9% bentonite (25°C 20%RH moisture absorption rate about 12%), 0.1% sodium hydroxide, 7% water %.

[0052] Chlorite is solid sodium chlorite with a purity of 80%.

[0053] Preparation method: Dissolve sodium hydroxide and water evenly, spray it evenly on bentonite by spraying, and then fully mix with solid sodium chlorite to prepare solid chlorine dioxide slow-release agent. The measured pH value of its 2% mass fraction aqueous suspension is 10.5, the sodium chlorite content is 4.05%, and the initial water content is 7.0%.

Embodiment 2

[0055] A solid chlorine dioxide slow-release agent, which consists of the following components in mass percentage: chlorite 6%, zeolite (25°C 20%RH moisture absorption rate about 10%) 84.8%, sodium carbonate 0.2%, water 9% .

[0056] Chlorite is solid sodium chlorite with a purity of 80%.

[0057] Preparation method: Dissolve chlorite, sodium carbonate, and water evenly, spray it evenly on the zeolite by spraying, mix well, and dry part of the water at 80°C to obtain solid chlorine dioxide sustained release agent. The measured pH value of its 2% mass fraction aqueous suspension is 9.8, the sodium chlorite content is 4.82%, and the initial water content is 5.0%.

Embodiment 3

[0059] A solid chlorine dioxide sustained-release agent, which consists of the following components in mass percentage: chlorite 6%, sepiolite (25°C 20%RH moisture absorption rate about 9%) 85%, sodium hydroxide 0.1%, Water 8.9%.

[0060] Chlorite is solid sodium chlorite with a purity of 80%.

[0061] Preparation method: Dissolve chlorite in water, spray it evenly on sepiolite by spraying, mix well, and dry part of the water at 80°C to prepare solid chlorine dioxide slow-release agent. The measured pH value of its 2% mass fraction aqueous suspension is 8.5, the sodium chlorite content is 4.80%, and the initial water content is 4.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com