An integrated 3D printing method for polyether ether ketone dental restorations in different colors

An oral restoration and 3D printing technology, applied in the field of oral restorations, can solve the problems of limited clinical indications, low hardness of resin materials, cumbersome processing procedures, etc., and achieve the goal of improving roughness, ensuring stability, and improving connection stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment discloses an integrated 3D printing method for polyether ether ketone dental restorations in different colors, including the following steps:

[0026] S1: Use a digital oral scanner to scan the surface morphology of the patient's upper and lower jaws, obtain the digital 3D model data of the patient's upper and lower jaws, and obtain the occlusal relationship between the upper and lower dentition;

[0027] S2: Import the obtained 3D data into the digital denture design software, and based on the 3D data, design the different parts of the digital dental restoration and adjust the overall occlusal relationship, and obtain the 3D data model of the dental restoration;

[0028] S3: Separate the 3D data model of the tooth and gingiva parts of the oral restoration, and design its connection interface, so as to obtain the printing data of the teeth and gingiva parts, and then import the printing data to the 3D printing device (Jugao-AMDoctor 200, Shaanxi Jugao Ad...

Embodiment 2

[0042] The teeth and gums of the oral restoration involved in this embodiment are all made of polyether ether ketone restoration materials; wherein, the polyetheretherketone tooth color material includes polyether ether ketone and toner powder, and the toner The powder is one of titanium oxide, zirconium oxide, and aluminum oxide, and the mass percentage of the toning powder is 2%-20%; the polyether ether ketone gum color material includes the following components: polyether ether ketone, iron oxide, Wherein the mass percentage of iron oxide is 0.2%-1.2%.

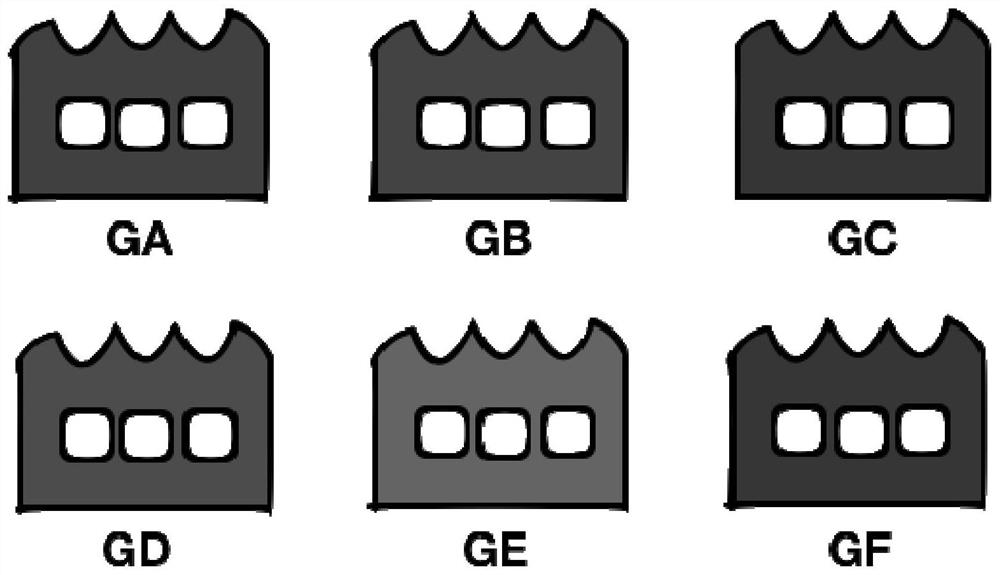

[0043] This example involves polyetheretherketone dental restoration tooth color shade guide and gum color shade guide;

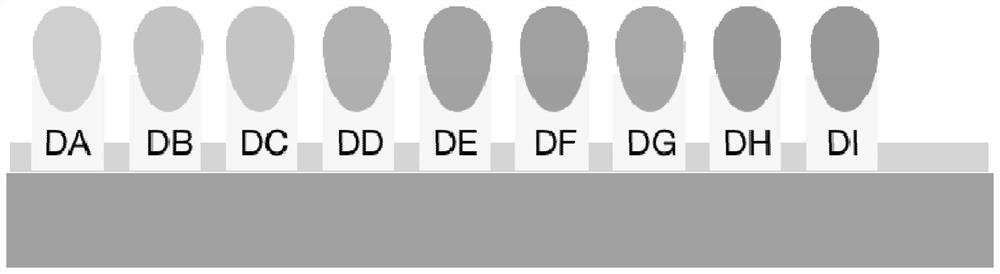

[0044] Among them, the polyetheretherketone oral restoration tooth color shade guide includes Dentin-A to Dentin-I, a total of nine color standard plates, among which, the DA color standard plate is made of polyetheretherketone and titanium oxide with a mass percentage of 3%. The DB color scale plate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com