Corrosion and scale inhibition reagent for oil and gas fields and preparation method thereof

A technology for corrosion and scale inhibition, oil and gas fields, applied in chemical instruments and methods, scale removal and water softening, special treatment targets, etc. , to meet the performance requirements of high pressure CO2 corrosion resistance, corrosion inhibition, mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Take 100ml of distilled water to dissolve 1g of ammonium persulfate, add 4g of acrylic acid monomer, 0.5g of acryl urea and 8g of isopropanol, adjust the pH of the solution to 7 with a mass fraction of 0.1% NaOH solution, adjust the temperature to 68°C, and stir evenly for pre-treatment. Poly 0.5h.

[0044] 20 g of acrylic acid monomer and 2 g of ammonium persulfate were dissolved in 40 g of water, and the pH value of the solution was adjusted to 6 with 0.1% NaOH solution. 5.3 g of allyl urea was dissolved in 10 g of ethanol. At the same time, use two dropping funnels to add the above two reactants dropwise to the reaction system for about 1 hour. Raise the temperature to 90°C, condense and reflux for 3h, and collect the product as a yellow solution.

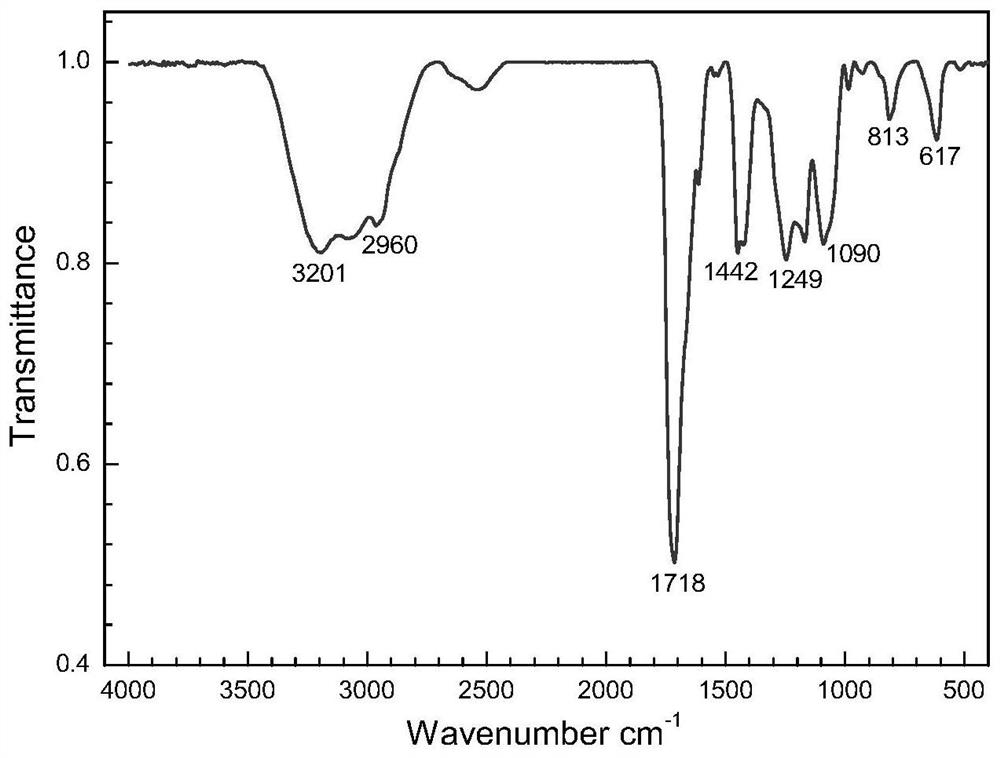

[0045] The product prepared by the present invention is carried out infrared test, figure 1 Acrylic acid and propylene urea polymerization product infrared test spectrum, infrared analysis results show: 3201cm -1 to 2...

Embodiment 2

[0054] a. Using distilled water as a solvent, add a certain amount of acrylic acid, and adjust the pH of the solution to 6 with a mass fraction of 0.13% NaOH solution. Add isopropanol, allyl urea and a small amount of ammonium persulfate, and carry out prepolymerization at 60°C, and the reaction time is 0.5h.

[0055] b. Dissolve the remaining acrylic acid and ammonium persulfate in water, adjust the pH of the solution to 7 with a mass fraction of 0.13% NaOH solution, and call it solution A. Dissolve the remaining allyl urea in a certain amount of ethanol, and record it as solution B.

[0056] c. Slowly add the above two solutions of A and B to the reaction system at the same time. After adding the liquid, raise the temperature to 90°C, condense and reflux and continue to stir for 3 hours to collect the product.

Embodiment 3

[0058] a. Using distilled water as a solvent, add a certain amount of acrylic acid, and adjust the pH of the solution to 9 with a mass fraction of 0.1% NaOH solution. Add isopropanol, allyl urea and a small amount of ammonium persulfate, and carry out prepolymerization at 75° C., and the reaction time is 1 h.

[0059] b. Dissolve the remaining acrylic acid and ammonium persulfate in water, adjust the pH of the solution to 9 with a 0.1% NaOH solution, and call it solution A. Dissolve the remaining allyl urea in a certain amount of ethanol, and record it as solution B.

[0060] c. Slowly add the above two solutions of A and B to the reaction system at the same time. After adding the liquid, raise the temperature to 95°C, condense and reflux and continue to stir for 4 hours to collect the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com