Solid-liquid composite lubricating system for reducing friction coefficient of moving part

A friction coefficient, solid-liquid composite technology, applied in lubricating compositions, ion implantation plating, coatings, etc., can solve the problem that the tribological behavior of solid lubricating films is easily affected by environmental factors, and reduce frictional shear. Effective force, reduced contact area, improved long life and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 A solid-liquid composite lubrication system that reduces the friction coefficient of moving parts. The system is composed of a solid lubricating film and lubricating oil.

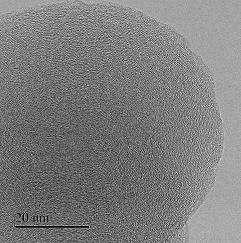

[0019] Among them: solid lubricating film means that the diamond-like carbon film is made of high-power pulse sputtering metal titanium or chromium as the bottom layer, and after 10-30 minutes of deposition, the diamond-like carbon film is deposited on the stainless steel surface. Methane and argon with a purity greater than 99.99% are introduced, and the gas pressure ratio of methane and argon is 1:1; the pulse bias is adjusted to 300V, the graphite target current is 5A, and the time is 120min to obtain a film with a thickness of 2.3 microns.

[0020] Lubricating oil refers to polyalphaolefin (PAO4) with additives (R 1 -CO-N-C 2 h 4 o 2 -B-OR 2 , where R 1 , R 2 It is the alkane chain) prepared according to the mass ratio of 200:1.

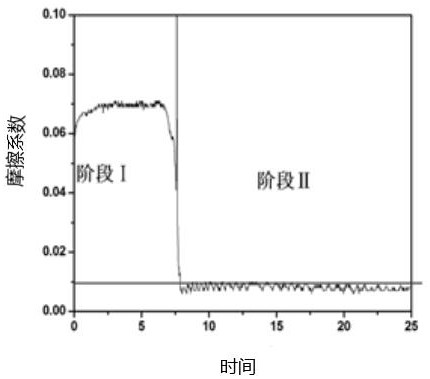

[0021] Taking GCr15 bearing steel as the friction...

Embodiment 2

[0022] Example 2 A solid-liquid composite lubrication system that reduces the friction coefficient of moving parts. The system is composed of a solid lubricating film and lubricating oil.

[0023] Among them: the solid lubricating film means that the molybdenum disulfide film is made of high-power pulse sputtering metal molybdenum as the bottom layer, and after 15 minutes of deposition, the molybdenum disulfide film is deposited on the surface of the tool steel. Introduce argon gas with a purity greater than 99.99%, adjust the pulse bias voltage to 400V, molybdenum disulfide target current to 8A, and time to 100min to obtain a film with a thickness of 2.1 microns.

[0024] Lubricating oil refers to alkane mineral oil and additives (R 1 -CO-N-C 2 h 4 o 2 -B-OR 2 , where R 1 , R 2 It is the alkane chain) prepared according to the mass ratio of 100:5.

[0025] Taking aluminum oxide as the frictional couple, under the conditions of load 10N and frequency 10Hz, the solid-liq...

Embodiment 3

[0026] Example 3 A solid-liquid composite lubrication system that reduces the friction coefficient of moving parts. The system is composed of a solid lubricating film and lubricating oil.

[0027] Among them: the solid lubricating film means that the titanium nitride film is made of high-power pulse sputtering metal titanium or chromium as the bottom layer, and after 20 minutes of deposition, the titanium nitride film is deposited on the stainless steel surface. Introduce nitrogen and argon with a purity greater than 99.99%, and the pressure ratio of nitrogen to argon is 2:1; adjust the pulse bias to 800V, titanium target current to 10A, and time to 80min to obtain a film with a thickness of 1.5 microns.

[0028] Lubricating oil refers to polyalphaolefin (PAO10) with additives (R 1 -CO-N-C 2 h 4 o 2 -B-OR 2 , where R 1 , R 2 It is the alkane chain) prepared according to the mass ratio of 150:2.

[0029] Taking silicon nitride as the frictional couple, under the conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com