Marsh gas factory tail gas processing system

An exhaust gas treatment and factory technology, applied in gas treatment, combustion type, separation method, etc., can solve problems such as injury, environmental pollution, and surrounding public dissatisfaction with public health, and achieve the effect of avoiding white smoke and equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

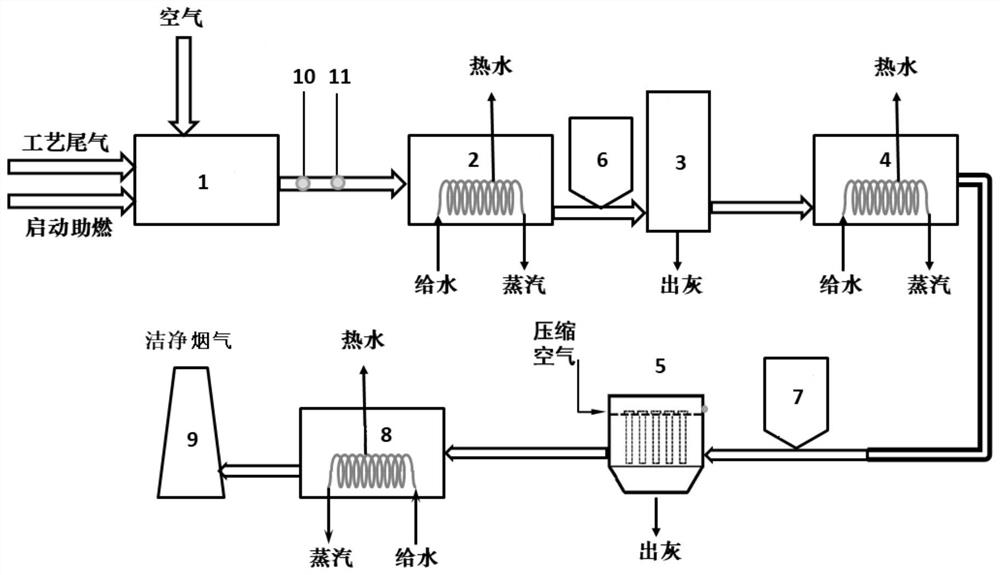

[0042] This embodiment provides a tail gas treatment system of a biogas plant, the treatment system includes an oxidation combustion device 1, a first waste heat recovery device 2, a desulfurization device 3, a second waste heat recovery device 4, a denitrification device 5, a first Three waste heat recovery devices 8 and a chimney 9;

[0043] An oxygen content measuring device 10 and a temperature measuring device 11 are sequentially arranged between the oxidation combustion device 1 and the first waste heat recovery device 2;

[0044] A desulfurization agent addition device 6 is provided between the first waste heat recovery device 2 and the desulfurization device 3 , and a denitration agent addition device 7 is provided between the second waste heat recovery device 4 and the denitration device 5 .

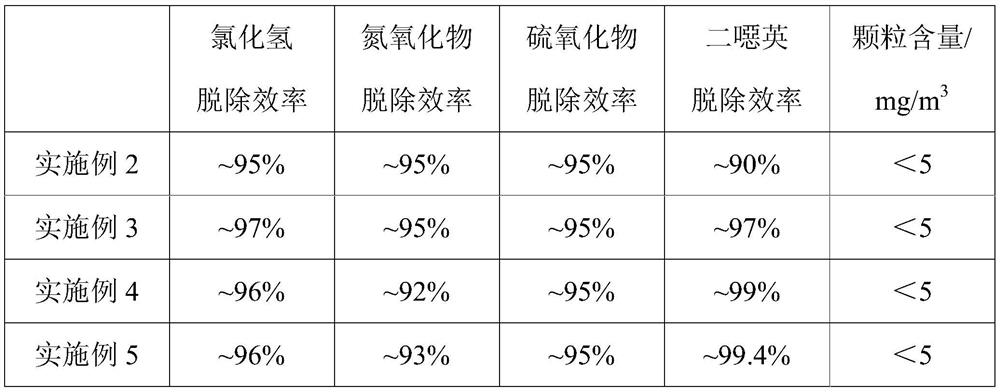

Embodiment 2

[0046] This embodiment provides a method for treating tail gas from a biogas plant, the method uses the tail gas treatment system of a biogas plant provided in Example 1, wherein the oxidation combustion device 1 is an oxidation furnace, the first waste heat recovery device 2, and the second waste heat recovery device 4 and the third waste heat recovery device 8 are waste heat boilers, gas-water heat exchangers or gas-gas heat exchangers, the desulfurization device 3 is a desulfurization reaction tower, and the denitrification device 5 is a ceramic fiber filter tube dust collector.

[0047] The treatment methods include:

[0048] The tail gas of the biogas factory enters the oxidation furnace for flameless combustion. When the oxidation furnace is started and ignited, biogas is used as an auxiliary fuel. The oxygen content measuring device 10 and the temperature measuring device 11 monitor the flue gas treated by the oxidation furnace; Enter the waste heat boiler for waste hea...

Embodiment 3

[0050] This embodiment provides a method for treating tail gas from a biogas factory, the method uses the tail gas treatment system of a biogas factory provided in Example 1, wherein the oxidation combustion device 1 is a thermal storage oxidation furnace, the first waste heat recovery device 2, the second waste heat The recovery device 4 and the third waste heat recovery device 8 are waste heat boilers, the desulfurization device 3 is a desulfurization reaction tower, and the denitrification device 5 is a ceramic fiber filter tube dust collector.

[0051] The treatment methods include:

[0052] The tail gas from the biogas factory enters the regenerative oxidation furnace for flameless combustion. When the regenerative oxidation furnace is started and ignited, biogas is used as an auxiliary fuel. The oxygen content measuring device 10 and the temperature measuring device 11 monitor the flue gas treated by the regenerative oxidation furnace; The flue gas treated by the thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com