A kind of composite lithium ion battery cathode material and preparation method thereof

A lithium-ion battery and positive electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of electrolyte side reactions, poor high-temperature performance, poor conductivity, etc., to increase volumetric energy density, improve high-temperature performance, Effect of Improving Magnification Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

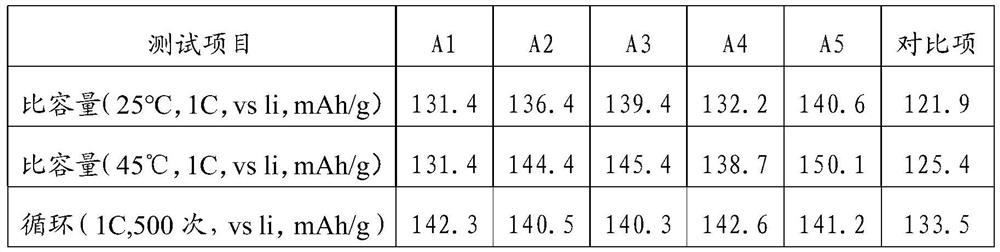

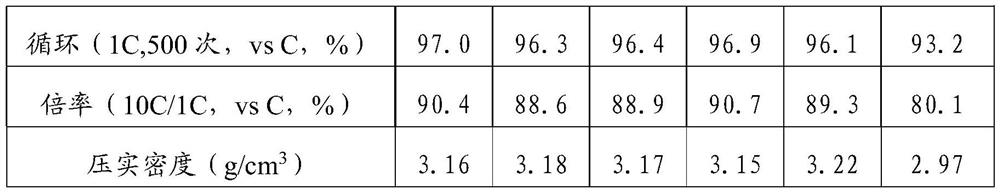

Examples

Embodiment 1

[0023] Embodiment 1: Composite lithium-ion battery cathode material and preparation method thereof

[0024] The composite lithium-ion battery cathode material is composed of spinel lithium manganese oxide and layered nickel-manganese binary material, wherein the mass ratio of spinel lithium manganate and layered nickel-manganese binary material is 8:2. The laser particle size of spinel-type lithium manganese oxide is 12.0μm~20.0μm, and the distribution width of spinel-type lithium manganate is less than 1.0, that is, [(D90-D10) / D50]<1.0, layered nickel-manganese binary material The laser particle size is 2.0μm~5.0μm.

[0025] According to the preparation method of the composite lithium-ion battery positive electrode material of above-mentioned formula composition, comprise the following steps:

[0026] (1) Preparation of trimanganese tetraoxide: Take a certain amount of deionized water and add it to the reaction kettle as the bottom liquid, turn on the stirring and heating de...

Embodiment 2

[0033] Embodiment 2: Composite lithium-ion battery cathode material and preparation method thereof

[0034] The composite lithium-ion battery cathode material is composed of spinel lithium manganese oxide and layered nickel-manganese binary material, wherein the mass ratio of spinel lithium manganate and layered nickel-manganese binary material is 8:2. The laser particle size of spinel-type lithium manganese oxide is 12.0μm-20.0μm, the distribution width of spinel-type lithium manganate is less than 1.0, and the laser particle size of layered nickel-manganese binary material is 2.0μm-5.0μm.

[0035] According to the preparation method of the composite lithium-ion battery positive electrode material of above-mentioned formula composition, comprise the following steps:

[0036] (1) The preparation of trimanganese tetroxide is the same as in Example 1.

[0037] (2) The preparation of spinel type lithium manganate is the same as in Example 1, and the prepared spinel type lithium ...

Embodiment 3

[0043] Embodiment 3: Composite lithium-ion battery cathode material and preparation method thereof

[0044] The composite lithium-ion battery cathode material is composed of spinel lithium manganese oxide and layered nickel-manganese binary material, wherein the mass ratio of spinel lithium manganate and layered nickel-manganese binary material is 8:2. The laser particle size of spinel-type lithium manganese oxide is 12.0μm-20.0μm, the distribution width of spinel-type lithium manganate is less than 1.0, and the laser particle size of layered nickel-manganese binary material is 2.0μm-5.0μm.

[0045] According to the preparation method of the composite lithium-ion battery positive electrode material of above-mentioned formula composition, comprise the following steps:

[0046] (1) The preparation of trimanganese tetroxide is the same as in Example 1.

[0047] (2) The preparation of spinel type lithium manganate is the same as in Example 1, and the prepared spinel type lithium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser granularity | aaaaa | aaaaa |

| laser granularity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com