Preparation method of high-strength cold-resistant modified glass wool fiber material

A glass wool fiber and modification technology, which is applied in the field of thermal insulation materials, can solve the problems of glass wool thermal insulation effect, tensile strength decline, and load-bearing deterioration, etc., to achieve large specific surface area, enhanced mechanical properties, high stiffness and strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

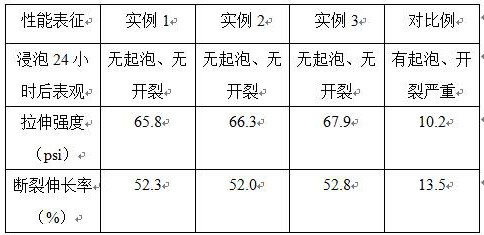

Embodiment 1

[0029] In parts by weight, weigh 45 parts of silicon dioxide, 10 parts of sodium oxide, 3 parts of quicklime, 1 part of magnesium oxide, 3 parts of aluminum oxide, 0.5 part of potassium oxide, 3 parts of boron oxide and 0.01 part of iron oxide in In the mixer, stir and mix and ball mill through a 200-mesh sieve, collect the ball-milled mixture and place it in a crucible, place the crucible in a resistance furnace, heat it up to 1280 °C at a rate of 5 °C / min, keep it melted and collect the molten solution, after 200 The orifice drain plate flows out, and the hole diameter of the drain plate is controlled to be 25mm. The fiber is collected once and straightened with a rubber roller with a line speed of 3m / min. The straightened fiber is collected and melted for the second time. Heat preservation and traction melting treatment at ℃, collect the secondary fibers and collect them with a cotton collector, control the negative pressure wind frequency to 40Hz, and obtain the matrix glas...

Embodiment 2

[0031] In parts by weight, weigh 47 parts of silicon dioxide, 13 parts of sodium oxide, 4 parts of quicklime, 1.5 parts of magnesium oxide, 4 parts of aluminum oxide, 0.7 part of potassium oxide, 4 parts of boron oxide and 0.03 part of iron oxide in In the mixer, stir and mix and ball mill through a 200-mesh sieve, collect the ball-milled mixture and place it in a crucible, place the crucible in a resistance furnace, heat up to 1340 °C at a rate of 5 °C / min, keep warm and melt, and collect the melt. After 200 The orifice drain plate flows out, the hole diameter of the drain plate is controlled to be 25mm, the fiber is collected once and straightened with a rubber roller with a line speed of 4m / min, the straightened fiber is collected and melted for the second time, the pulling speed of the rubber roller is controlled to be 275m / s, at 1450 Heat preservation and traction melting treatment at ℃, collect the secondary fibers and collect them with a cotton collector, control the neg...

Embodiment 3

[0033] In parts by weight, weigh 50 parts of silicon dioxide, 15 parts of sodium oxide, 5 parts of quicklime, 2 parts of magnesium oxide, 5 parts of aluminum oxide, 1.0 part of potassium oxide, 5 parts of boron oxide and 0.05 part of iron oxide in In the blender, stir and mix and ball mill through a 200-mesh sieve, collect the ball-milled mixture and place it in a crucible, place the crucible in a resistance furnace, heat up to 1400 °C at a rate of 5 °C / min, keep warm and melt, and collect the melt. After 200 The orifice drain plate flows out, and the hole diameter of the drain plate is controlled to be 25mm. The fiber is collected once and straightened with a rubber roller with a line speed of 5m / min. The straightened fiber is collected and melted for the second time. Heat preservation and traction melting treatment at ℃, collect the secondary fibers and collect them with a cotton collector, control the negative pressure wind frequency to 45Hz, and obtain the matrix glass wool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com