Formula and preparation method of high-speed extruded PVC coated yarn color master batch

A high-speed extrusion and color masterbatch technology, applied in the field of PVC coated wire, can solve the problems of slow production speed, low dynamic viscosity, and fast coating speed, so as to save manufacturing costs, meet coating speed, and eliminate discoloration. spot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

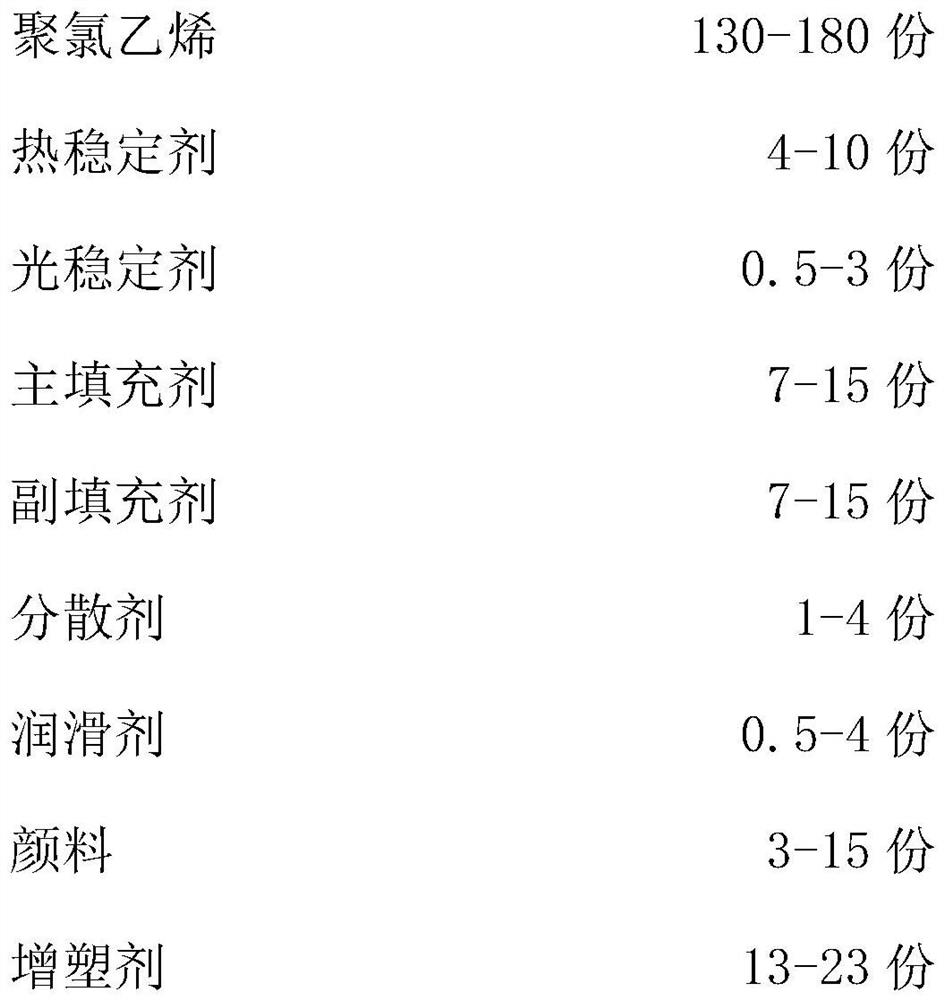

[0038] A high-speed extrusion PVC-coated silk masterbatch formula of the present embodiment includes the following raw materials in parts by mass:

[0039]

[0040] The preparation method of a kind of high-speed extruded PVC coated silk masterbatch formula of the present embodiment comprises the following steps:

[0041]S1. Prepare group A: Pour polyvinyl chloride (general-purpose SG-5) into the first mixing tank, then add HT-3000A, UV-326 and P-EPQ into the mixing tank and stir for 1-2 minutes;

[0042] S2. Prepare B group materials: put 0.36μm titanium dioxide, 2000 mesh calcium carbonate powder, 125 mesh EBS, CWO-315 into the second mixing tank, stir for 1-2 minutes, add macromolecular organic pigments according to the color requirements, Stir for another 3-4 minutes at 150-155°C;

[0043] S3. Pour the material of group A into the material of group B, drop in HC-160 and epoxy soybean oil while stirring, and gradually increase the stirring temperature to 202-204°C, stir ...

Embodiment 2

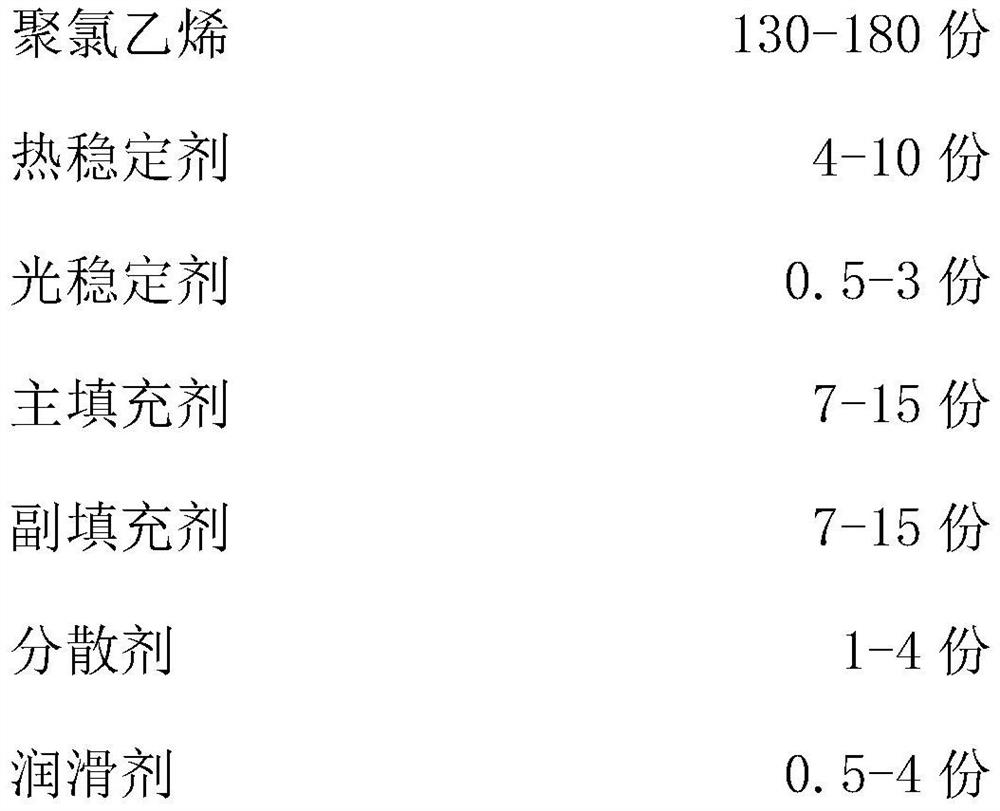

[0046] A high-speed extrusion PVC-coated silk masterbatch formula of the present embodiment includes the following raw materials in parts by mass:

[0047]

[0048] The preparation method of a kind of high-speed extruded PVC coated silk masterbatch formula of the present embodiment comprises the following steps:

[0049] S1. Prepare A group of materials: pour polyvinyl chloride (general-purpose SG-5) into the first mixing tank, then add HT-3000A, UV-326 and triphenyl phosphate into the mixing tank and stir for 1-2 minutes;

[0050] S2. Prepare B group materials: put 0.36μm titanium dioxide, 2000 mesh calcium carbonate powder, 125 mesh EBS, CWO-315 into the second mixing tank, stir for 1-2 minutes, add macromolecular organic pigments according to the color requirements, Stir for another 3-4 minutes at 150-155°C;

[0051] S3. Pour the material of group A into the material of group B, drop in HC-160 and epoxy soybean oil while stirring, and gradually increase the stirring tem...

Embodiment 3

[0054] A high-speed extrusion PVC-coated silk masterbatch formula of the present embodiment includes the following raw materials in parts by mass:

[0055]

[0056]

[0057] The preparation method of a kind of high-speed extruded PVC coated silk masterbatch formula of the present embodiment comprises the following steps:

[0058] S1. Prepare A group of materials: Pour polyvinyl chloride (general-purpose SG-5) into the first mixing tank, then add HT-3000A, UV-326, P-EPQ and triphenyl phosphate into the mixing tank and stir for 1-2 minute;

[0059] S2. Prepare B group materials: put 0.36μm titanium dioxide, 2000 mesh calcium carbonate powder, 125 mesh EBS, CWO-315 into the second mixing tank, stir for 1-2 minutes, add macromolecular organic pigments according to the color requirements, Stir for another 3-4 minutes at 150-155°C;

[0060] S3. Pour the material of group A into the material of group B, drop in HC-160 and epoxy soybean oil while stirring, and gradually increa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com