Starter, direct-injection fermentation method of stinky tofu brine and stinky tofu brine

A fermentation method and technology of starter, which are applied in microorganism-based methods, biochemical equipment and methods, bacteria used in food preparation, etc. The effect of shortening the soaking production cycle, reducing the risk of food safety, and clarifying the fermentation strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1, the separation and identification of lactic acid bacteria

[0051] The specific steps are as follows:

[0052] (1) Dilute the collected kimchi and sour dough by 10 times with sterile physiological saline, and dilute to 10 -3 and 10 -5 times, take 200 μL of diluent and evenly spread it on MRS solid medium (MRS medium mixture 48.3g / L, containing 2% agar, sterilized at 115°C), incubate upside down in a constant temperature incubator at 37°C for 48h, take out and pick A single colony was cultured in 10 mL of MRS liquid medium (containing 2% agar) at 37° C. in a constant temperature shaker for 18 h at a rotational speed of 200 rpm.

[0053] (2) After the bacterial liquid was obtained, DNA was extracted with a DNA extraction kit, and the 16S rRNA fragment was subjected to polymerase chain reaction. The primers were shown in Table 1, the reaction system was shown in Table 2, and the reaction conditions were shown in Table 3.

[0054] (3) The amplified products...

Embodiment 2

[0065] Embodiment 2, the preparation of lactic acid bacteria freeze-dried bacteria powder

[0066] In an aseptic operation table, pick out a small amount of bacterial liquid from the glycerol tubes that preserve Lactobacillus plantarum KS1-1, Lactobacillus plantarum KS1-2, Lactococcus lactis ZJL1-3 and Pediococcus pentosaceus ZJL2-2, and put them on the MRS solid plate. Overline, culture at 37°C for 36-48h, pick a single colony on the plate and inoculate it into 10mL liquid MRS medium, inoculate it in a 10L fermenter containing MRS medium after anaerobic culture at 37°C for 18h, and anaerobic fermentation for 24h , and then centrifuged at 6000 rmp for 10 min to collect bacterial cells, and washed twice with sterile phosphate buffer (pH=6.4). Centrifuge and mix the obtained bacterial paste with skim milk powder containing 18%-22%, 4-9% trehalose, 2-4% sodium glycinate, 1-5% glycerol and 0.1-1% (w / w) half tube The sterilized lyoprotectant of amino acid hydrochloride is thorough...

Embodiment 3-6、4

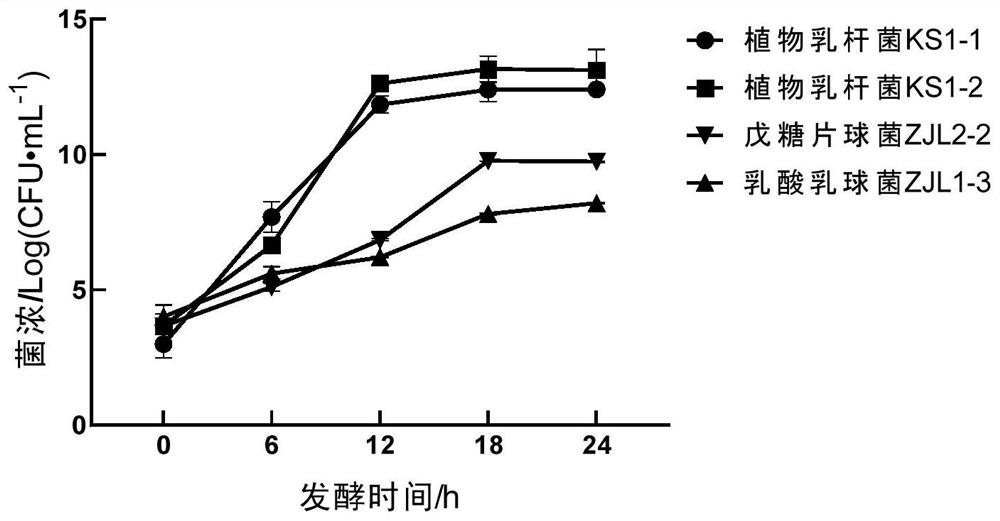

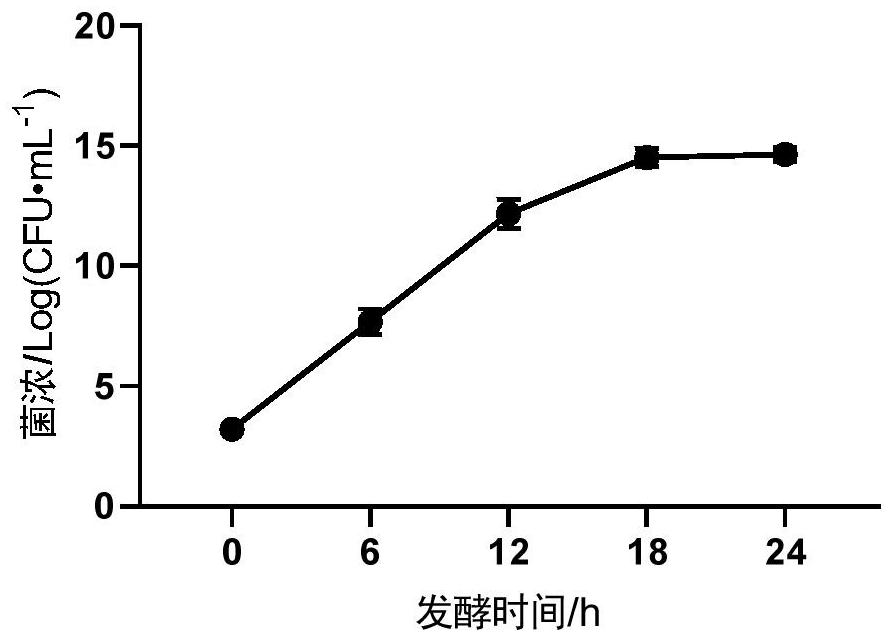

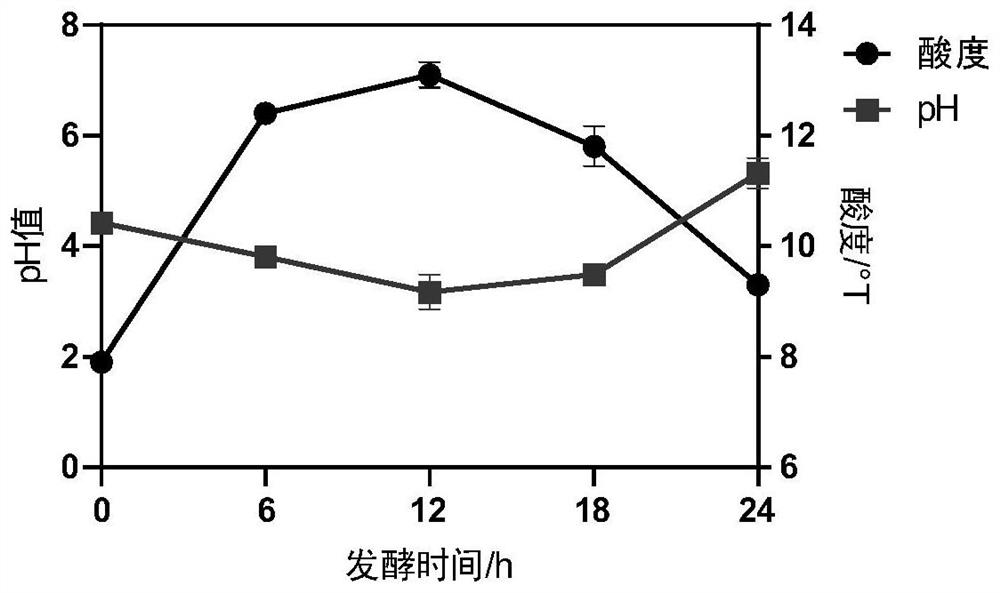

[0067] Embodiment 3-6, 4 strains of lactic acid bacteria carry out the fermentation of stinky tofu brine alone

[0068] 4 strains of lactic acid bacteria are used as starter alone to ferment brine stock solution, and the specific steps are as follows:

[0069] (1), prepare brine stoste, the component of described brine stoste includes amaranth stalk, ginger, Chinese prickly ash and sterile saline, wherein, the concentration of described amaranth stalk is 12.25g / 100mL, and the concentration of described ginger is 1.25 g g / 100mL, the concentration of the prickly ash is 0.63g / 100mL, and the concentration of the sterile saline is 2g / 100mL.

[0070] (2), inoculate the starter in the brine stock solution of step (1), the initial total concentration of the starter in the brine stock solution is about 10 4 CFU / mL, cultured at 37°C for 12h, then put crushed bean curd in a volume ratio of 2% as a nitrogen source for fermentation, and continued to ferment at 37°C for 12h to obtain stink...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com