A kind of green recovery processing method of waste lithium iron phosphate battery positive electrode

A lithium iron phosphate battery, recycling and processing technology, applied in battery recycling, battery electrode, waste collector recycling and other directions, can solve the problems of alkali and strong corrosiveness of sodium hydroxide recovery assistant, and achieve low cost and corrosiveness. Small and easy to industrialize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 10g LiFePO 4 The powder is stirred and mixed with the sodium carbonate solid according to the ratio of 1:2, and placed in a ball mill for 5 minutes to make it fully mixed;

[0028] (2) Heating the material in step (2) to 700°C for solid phase sintering, the reaction time is 4h, and naturally cooling to room temperature after the reaction;

[0029] (3) For the sintered material in step (2), make slurry according to the liquid-solid ratio of 4:1, weigh 2g of the sintered product, slowly add deionized water into the container containing the sintered product, and keep stirring during the water addition process. Continue stirring for 30 min after all the addition is complete, and obtain Li respectively after the filtration is completed. x Fe y o 2 filter cake and sodium phosphate solution;

[0030] (4) the filter cake obtained in step (3) is washed to obtain Li x Fe y o 2 ;

[0031] (5) step (3) filtrate is evaporated and concentrated to obtain Na 3 PO 4 ...

Embodiment 2

[0033] The difference is that LiFePO 4 with Na 2 CO 3 The molar ratio of substances is 1:1.5, and the rest are the same as in Example 1.

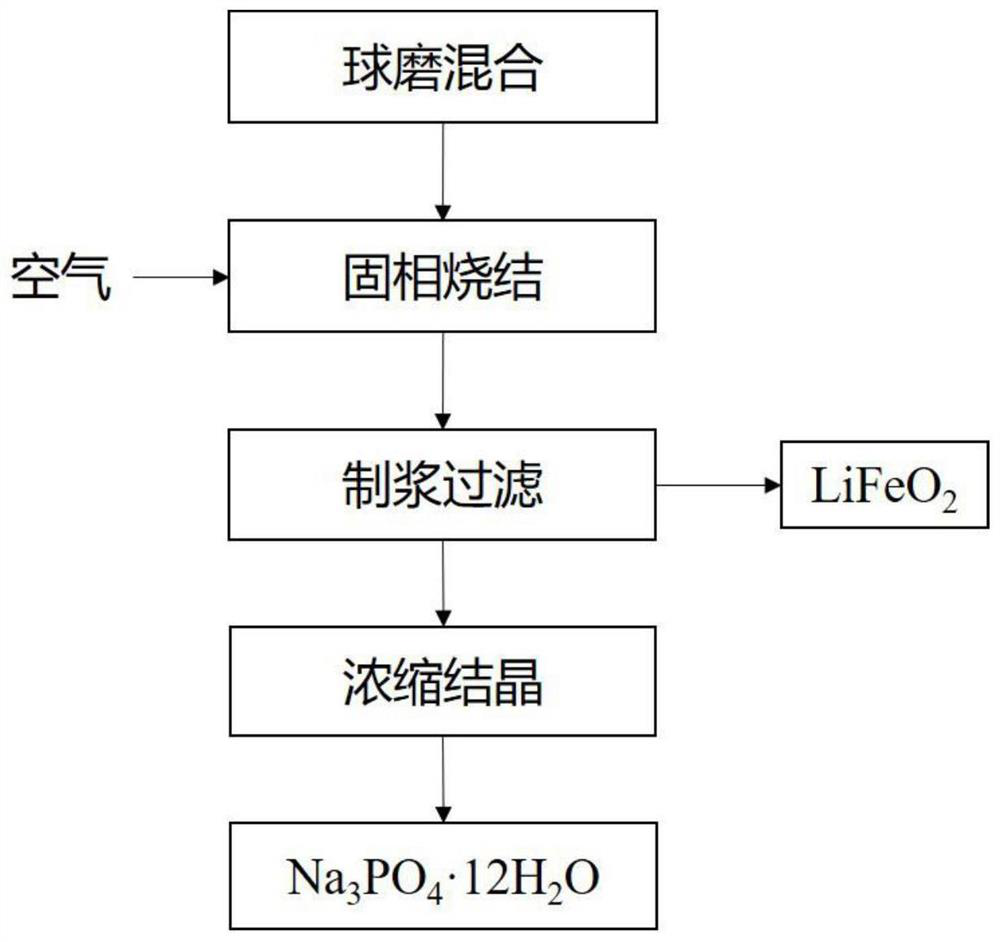

[0034] figure 1 It is a flow chart of the green recycling process of the positive electrode of the waste lithium iron phosphate battery.

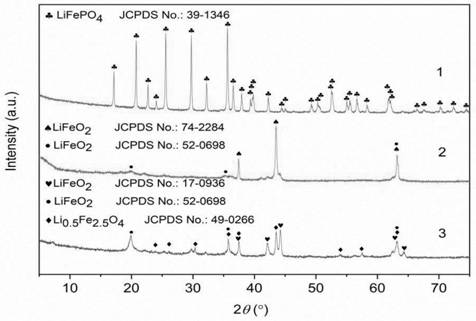

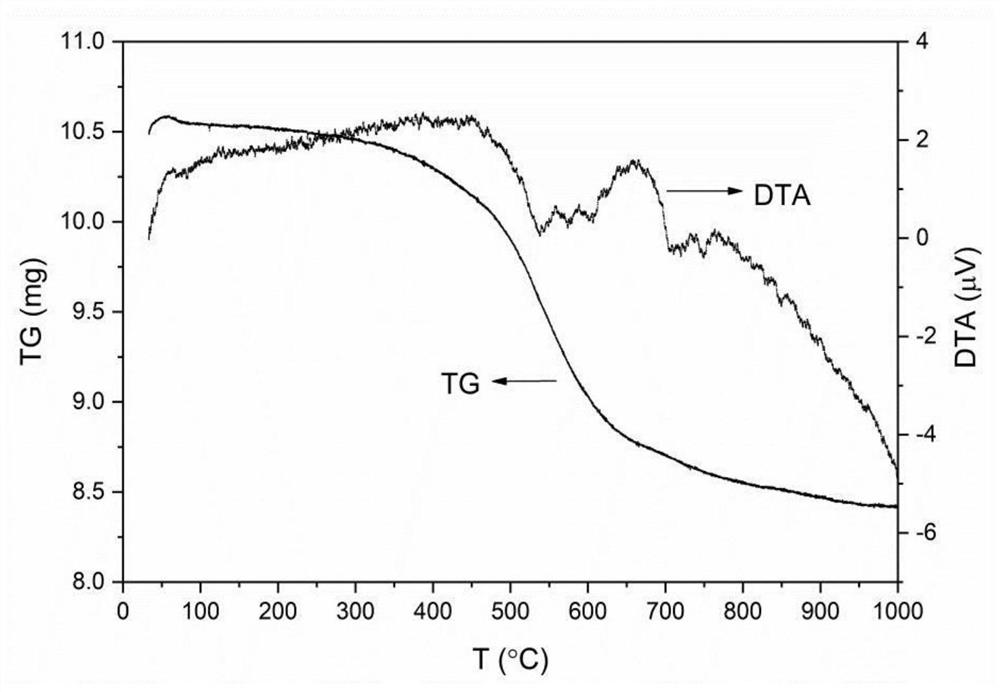

[0035] figure 2 For LiFePO in Example 1 4 with Na 2 CO 3 The TG-DTA curve of the mixture; in the process of 300~540℃, Na 2 CO 3 start to decompose to produce CO 2 , the mass loss is obvious, accompanied by LiFePO 4 The breaking of the internal Fe-P bond and the Na 3 PO 4 The formation of chemical bonds; 540 ~ 700 ° C process, it may be that ferrous iron absorbs oxygen in the air and is oxidized to lithium iron (Ⅲ) oxide (LiFeO 2 ) process; 700 ~ 1000 ℃ exothermic process, LiFeO 2 The process of crystal phase transformation; through the above analysis, it is determined that the sintering temperature is 700 ° C, and holding it for a certain period of time is beneficial to LiFeO 2 Formation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com