Adsorbent and preparation method and application thereof

An adsorbent and reaction technology, applied in the field of environmental remediation, can solve problems such as failure to meet emission standards, weak adsorption capacity of the adsorbent, weak adsorption capacity of ammonium nitrogen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

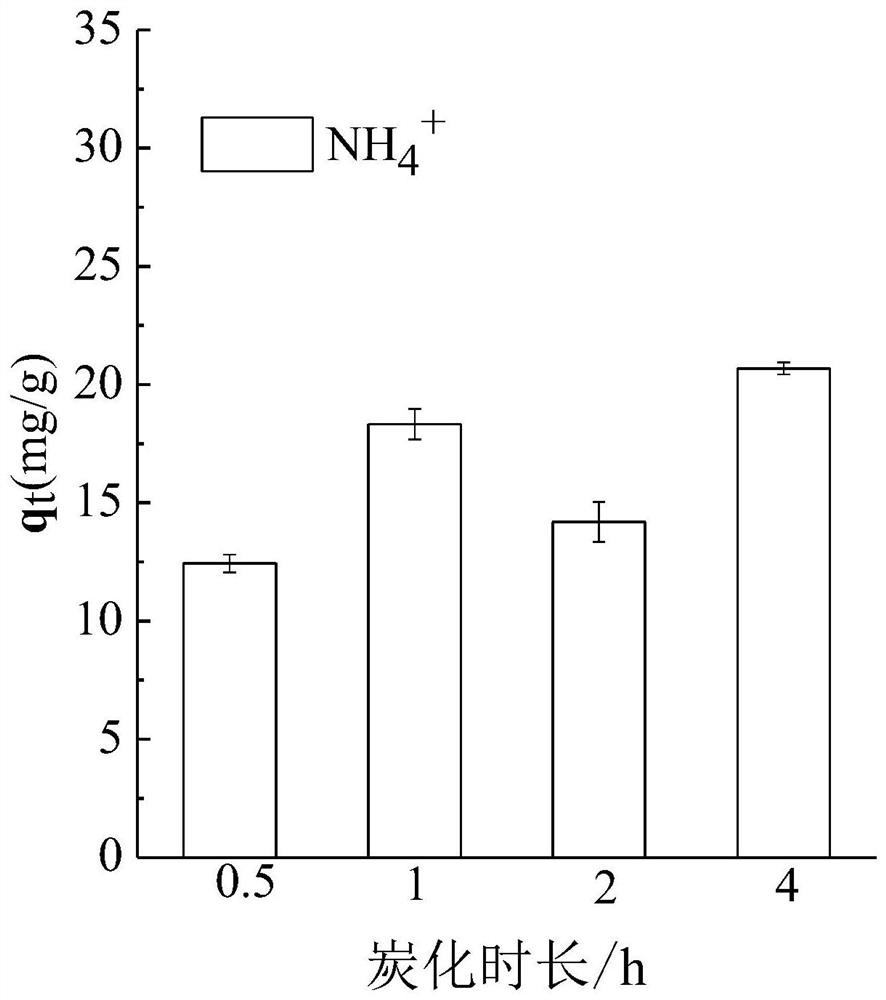

[0041] The embodiment of the present application provides the adsorption performance test of the adsorbent prepared by different pyrolysis temperatures and times, and the specific steps are as follows:

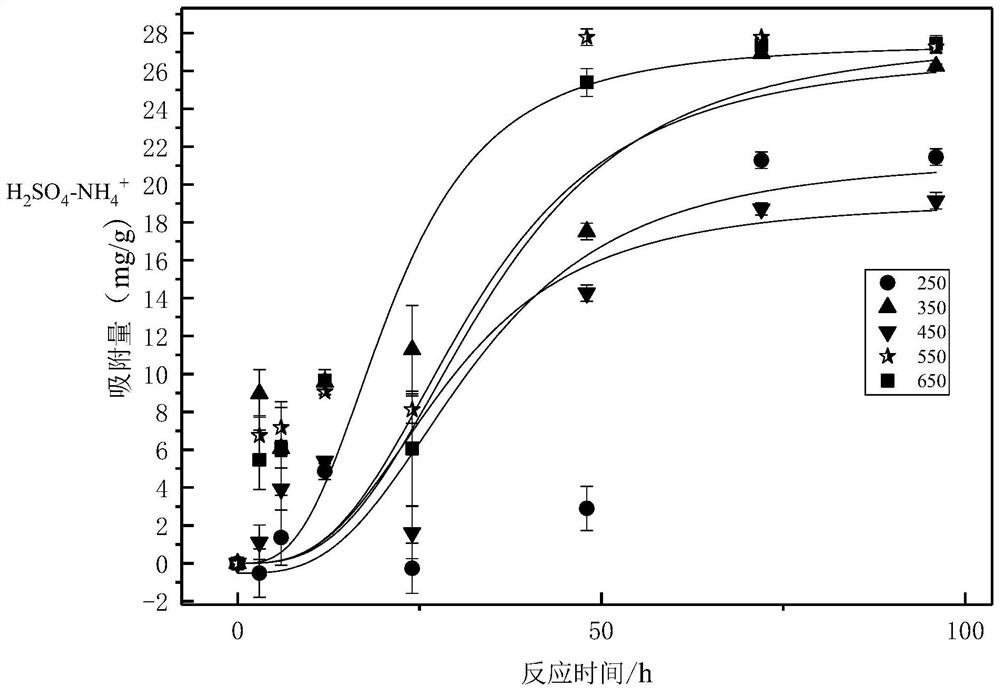

[0042] 1. Adsorbents prepared at different pyrolysis temperatures adsorb NH in water 4 + The reaction equilibrium time of :

[0043] 1. Acquisition of scallion plant powder: select healthy and well-growing aquatic plant scallion, after cleaning, cutting, drying, crushing, sieving, etc., put it into a sealed bag and put it in a desiccator for use. Get scallion plant powder.

[0044]2. Weigh 50g of scallop plant powder through 80 mesh sieve and soak in 1000mL of 20%H 2 SO 4 solution, after mixing, place it in a constant temperature oscillator at 120rmp and 25°C for 24h. Centrifuge the shaken sample mixture in a centrifuge at 8000r / min for 10min, remove the upper layer solution, dry the remaining mixture in an oven at 80°C, put an appropriate amount in a quartz ark, put it i...

Embodiment 3

[0069] The embodiment of the present application provides the influence of external factors on the adsorption performance of the adsorbent of Dahe biochar, and the specific steps are as follows:

[0070] (1) Influence of eutrophication water body pH on the adsorption performance of the stalk biochar adsorbent of the embodiment of the present application:

[0071] Take 0.2g of HPS-450-1 prepared above and add it into a 250mL conical flask filled with 200mL of simulated eutrophication water, set 3 parallel samples in each group, adjust the concentration of simulated eutrophication water with NaOH and HCl The initial pH of the solution is 3, 5, 7, 9, 11 respectively. After capping, oscillate and absorb in a constant temperature oscillator at 200r / min and 25°C for 72h, take it out, draw the supernatant into a 50mL centrifuge tube with a syringe, and After centrifugation with a speed of 8000r / min for 10min, use a 0.45μm pore size microporous filter membrane to filter, and measure t...

Embodiment 4

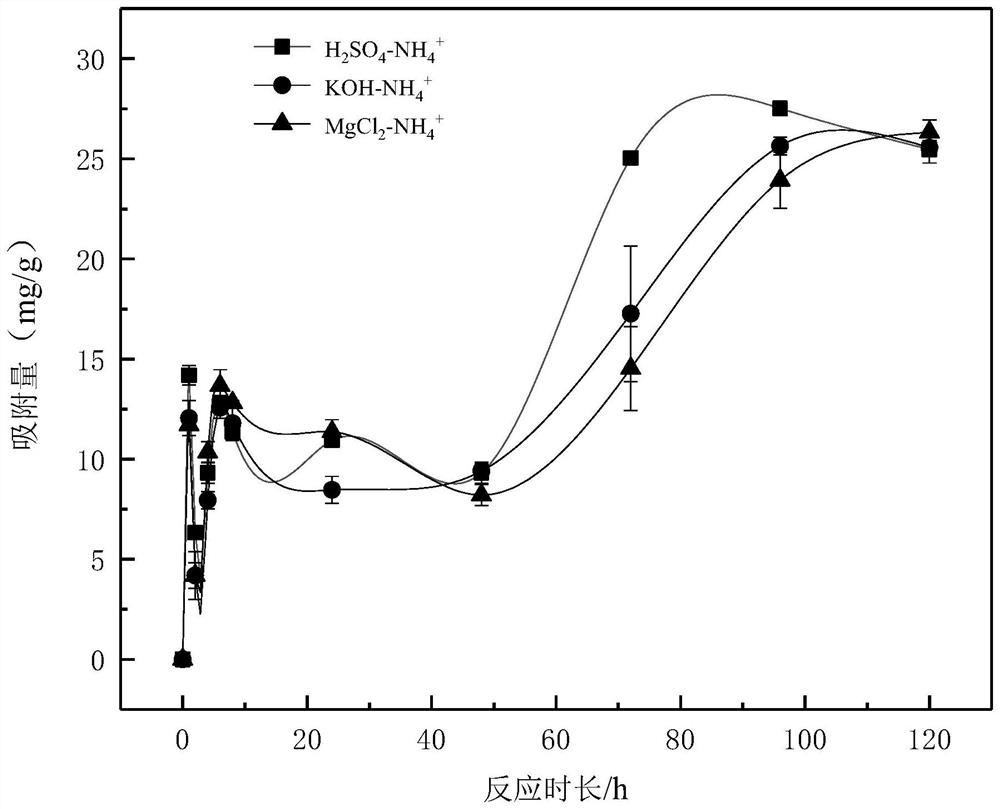

[0077] The embodiment of the present application provides the effect of using the modifier and not using the modifier to prepare the Dazai biomass charcoal adsorbent on the adsorption and purification of eutrophic water. The steps are as follows:

[0078] 1. Acquisition of scallion plant powder: select healthy and well-growing aquatic plant scallion, after cleaning, cutting, drying, crushing, sieving, etc., put it into a sealed bag and put it in a desiccator for use. Get scallion plant powder.

[0079] 2. Weigh 50g of the scallop plant powder passed through the 80-mesh sieve without modification, put it directly in the quartz ark, put it into the tube furnace and cover it, and keep the flow rate of 40ml / min in the tube furnace Introduce nitrogen to keep the furnace in an oxygen-free or oxygen-deficient state. Set the program parameters so that the tube furnace maintains a heating rate of 10°C / min and continues to heat up to 450°C. After the pyrolysis is maintained at a constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com