Magnetic magnesium ferrite biochar composite microsphere phosphorus removal adsorbent, and preparation method and application thereof

A technology of composite microspheres and phosphorus adsorbents, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve problems such as limiting the industrialization of biochar application materials, fixed bed clogging, and easy shedding , to achieve the effect of preventing the loss of nano-magnesium ferrite, good regeneration, and increasing mass transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

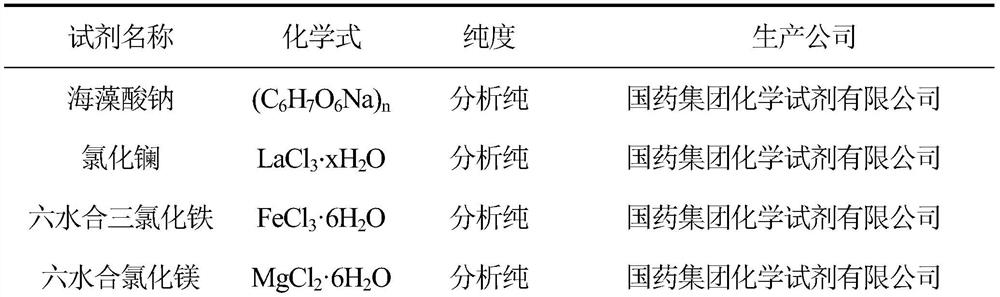

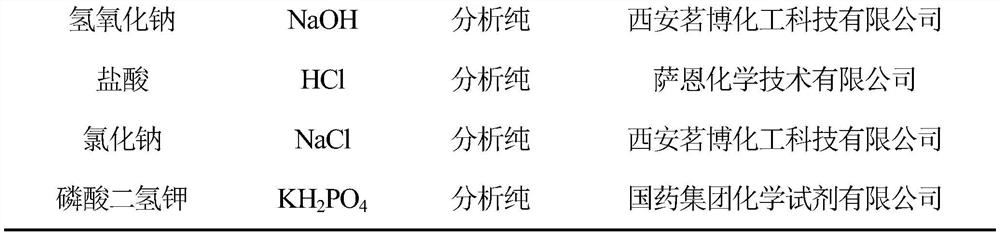

[0039] 0.03mol MgCl 2 and 0.06mol FeCl 3 Dissolve in 100mL of ultra-pure water, add 5.0g of reed biomass powder, stir evenly, add 1mol / L NaOH solution drop by drop to pH 11, vibrate at 150rpm at 70°C for 2h, filter, wash and dry . Add the precursor to an aqueous solution of sodium alginate (mass concentration of 2% w / v), stir evenly, and drop the mixed slurry into the crosslinking solution of lanthanum chloride (mass concentration of 3% w / v) with a dropper , to obtain cross-linked pellets, after hardening for 15 hours, wash and dry. The dried pellets were placed in a tube furnace and pyrolyzed at 600° C. for 2 h under the protection of nitrogen to obtain a magnetic magnesium ferrite biochar composite microsphere phosphorus-removing adsorbent.

Embodiment 2

[0041] 0.03mol MgCl 2 and 0.05mol FeCl 3 Dissolve in 100mL of ultra-pure water, add 5.0g of reed biomass powder, stir evenly, add 1mol / L NaOH solution drop by drop to pH 11, vibrate at 150rpm at 70°C for 2h, filter, wash and dry . Add the precursor to the sodium alginate aqueous solution (mass concentration is 3% w / v), after stirring evenly, drop the mixed slurry into the cross-linking solution of lanthanum chloride (mass concentration is 4% w / v) with a dropper , to obtain cross-linked pellets, after hardening for 15 hours, wash and dry. The dried pellets were placed in a tube furnace and pyrolyzed at 700°C for 2 hours under the protection of nitrogen to obtain a magnetic magnesium ferrite biochar composite microsphere phosphorus-removing adsorbent.

Embodiment 3

[0043] 0.03mol MgCl 2 and 0.05mol FeCl 3Dissolve in 100mL of ultra-pure water, add 5.0g of reed biomass powder, stir evenly, add 1mol / L NaOH solution drop by drop to pH 11, vibrate at 150rpm at 70°C for 2h, filter, wash and dry . Add the precursor to the sodium alginate aqueous solution (mass concentration is 3% w / v), after stirring evenly, use a dropper to drop the mixed slurry into the crosslinking solution of lanthanum chloride (mass concentration is 5% w / v) , to obtain cross-linked pellets, after hardening for 15 hours, wash and dry. The dried pellets were placed in a tube furnace and pyrolyzed at 800°C for 2 hours under the protection of nitrogen to obtain a magnetic magnesium ferrite biochar composite microsphere phosphorus-removing adsorbent.

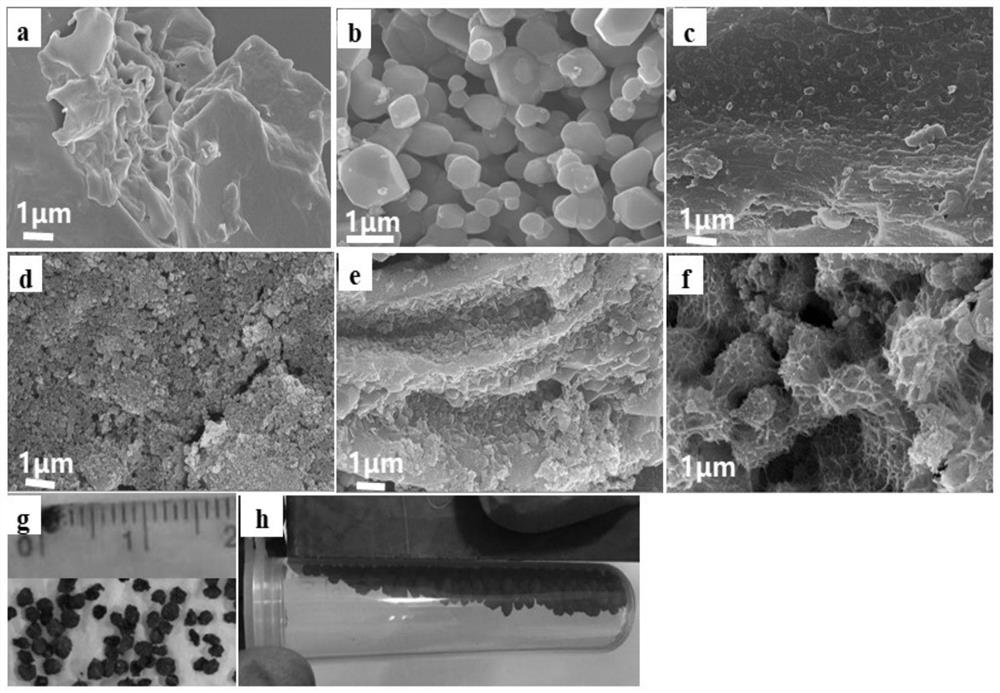

[0044] From figure 1 It can be seen that the prepared example 3 becomes reddish brown, and the diameter of the microspheres is between 2.5-3.5mm, and has stronger magnetic properties ( figure 1 middle g-h). The surface of b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com