Novel preparation method of 3-alkenyl benzyne liquid crystal compound

A technology for liquid crystal compounds and alkenyl benzynes, which is applied in the preparation of hydroxyl compounds, the preparation of organic compounds, and the preparation of carbonyl compounds by oxidation, which can solve the problems of double bond migration, affecting product quality and effective utilization of raw materials, and difficulty in purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

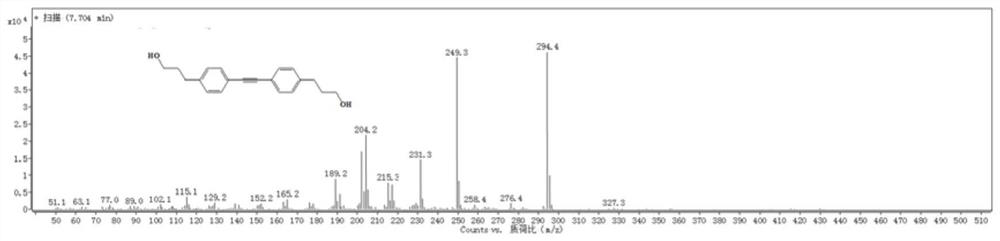

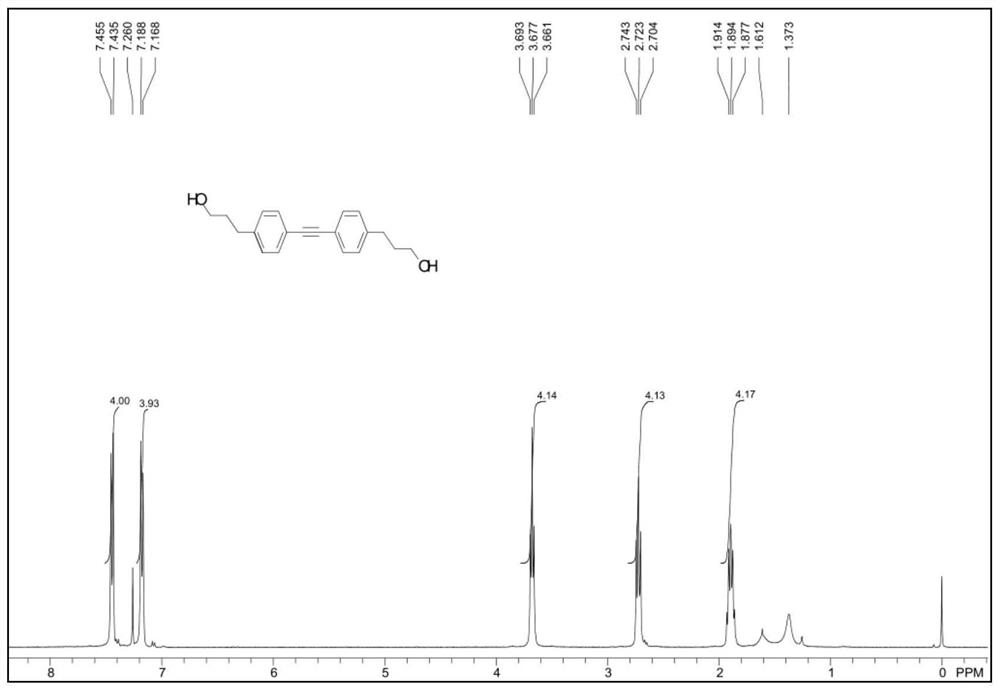

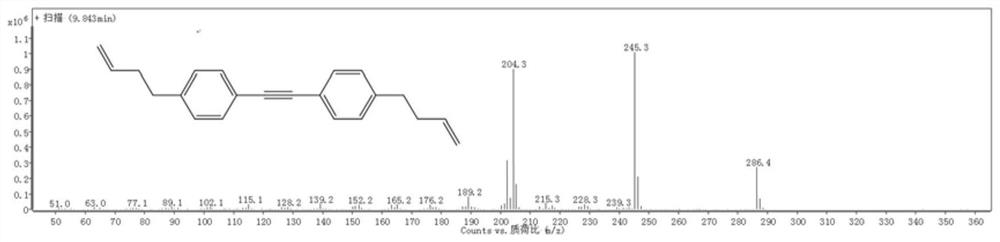

[0077] A kind of preparation method of bis-[4-(3-butene)]-1,1'-toluene liquid crystal compound

[0078] The preparation of step 1 intermediate I-1:

[0079]

[0080] Add 66g of phenylpropionic acid, 1000ml of acetic acid, 270ml of water, 25ml of concentrated sulfuric acid, 25g of sodium iodate and 25g of iodine particles into the three-necked flask in sequence, stir and raise the temperature to reflux at a temperature of about 105°C, and react for 8 hours. After treatment, stop heating, cool the cooling water to 50°C, add sodium bisulfite solution, the system fades to light yellow and precipitate solids, add deionized water, add toluene for extraction, wash with water, vacuum precipitation, crystallization, and obtain intermediate I -1 white powder 86g, yield 70%.

[0081] The preparation of step 2 intermediate I-2:

[0082]

[0083] Add 150ml of anhydrous methanol and 85g of p-iodophenylpropionic acid into the three-necked flask, stir to completely dissolve, then slow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com