Method for manufacturing high-purity vaterite-type and calcite-type calcium carbonate by using indirect carbonation of seawater

A calcite-type, carbonation technology, applied in calcium carbonate/strontium/barium, chemical instruments and methods, separation methods, etc., can solve the problems of reducing the economical efficiency of indirect carbonation technology and increasing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

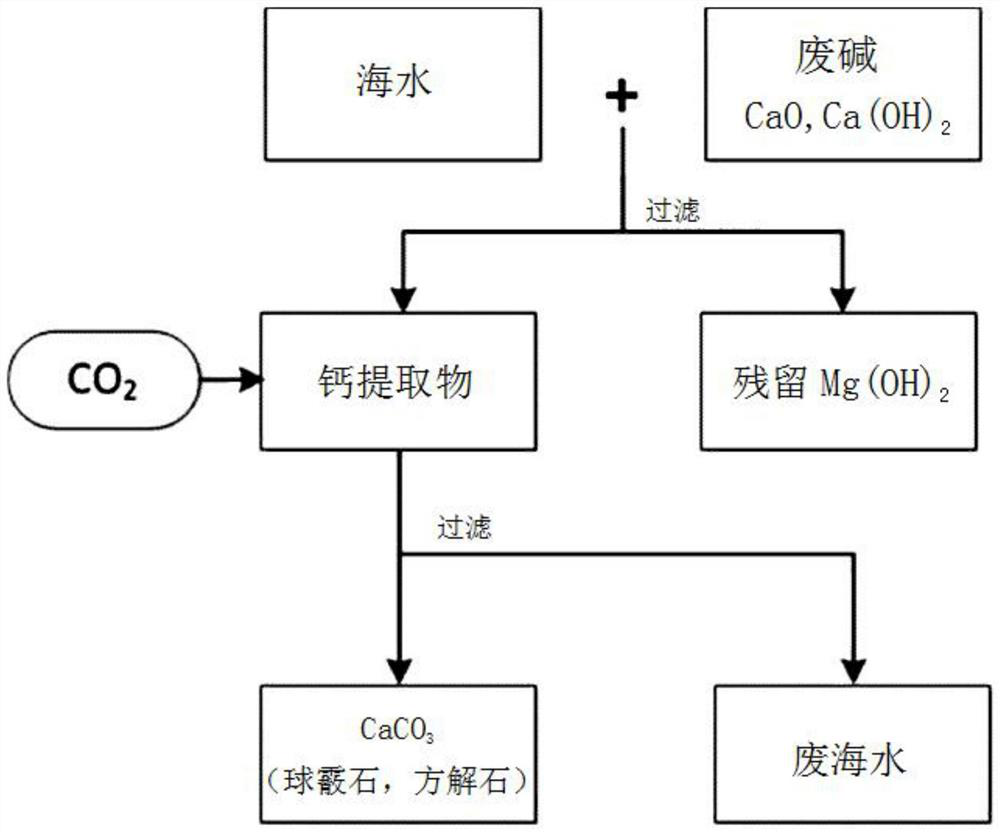

[0076] Preparation Example 1: Raw material for ensuring indirect carbonation reaction (Ca Source)

[0077] In this example, the by-products of alkali industry, calcium oxide (CaO) and calcium hydroxide (Ca(OH) 2 ) reagents as raw materials for indirect carbonation reactions. Cement kiln dust (CKD) and paper sludge ash (PSA) were used as by-products of the alkali industry. Each industrial by-product is sieved through a 425μm sieve and used. For calcium oxide, a Hayashi Pure Chemical Ind. reagent (assaymin. 98%) was used, and for calcium hydroxide, a Junsei Chemical reagent (assaymin. 96%) was used.

[0078] The effective particle size of CKD used in this example is 23.6, and the chemical composition analysis results using XRF (X-ray fluorescence spectrometer: X-ray fluorescence spectrometer) equipment are shown in Table 2 below.

[0079] [Table 2]

[0080]

preparation example 2

[0081] Preparation example 2: Ensuring seawater and seawater desalination concentrated water

[0082] Solvents for indirect carbonation reactions use seawater and desalinated concentrated water. The seawater is used for taking water from the coast, and the desalination concentrated water is used for taking water from the seawater desalination plant. Seawater and concentrated water were immediately filtered with 5 μm filter paper (FilterPaper 2, ADVANTEC) and stored in cold storage.

[0083] The pH of the seawater used in this example is 7.97, and the calcium and magnesium concentrations measured by an atomic absorption spectrophotometer are 474㎎ / L and 1,322㎎ / L, respectively, which are similar to ordinary seawater.

[0084] In addition, the pH of the desalinated concentrated water used in this example was 7.82, and the calcium and magnesium concentrations were 900 ㎎ / L and 3,900 ㎎ / L, respectively.

Embodiment 1

[0085] Embodiment 1: Utilize seawater to prepare calcium dissolution solution

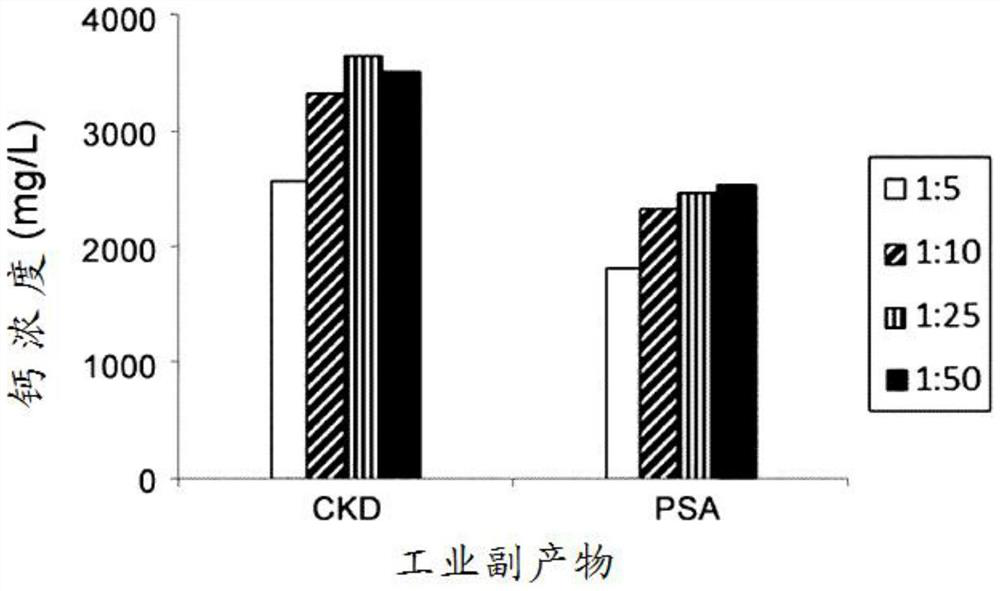

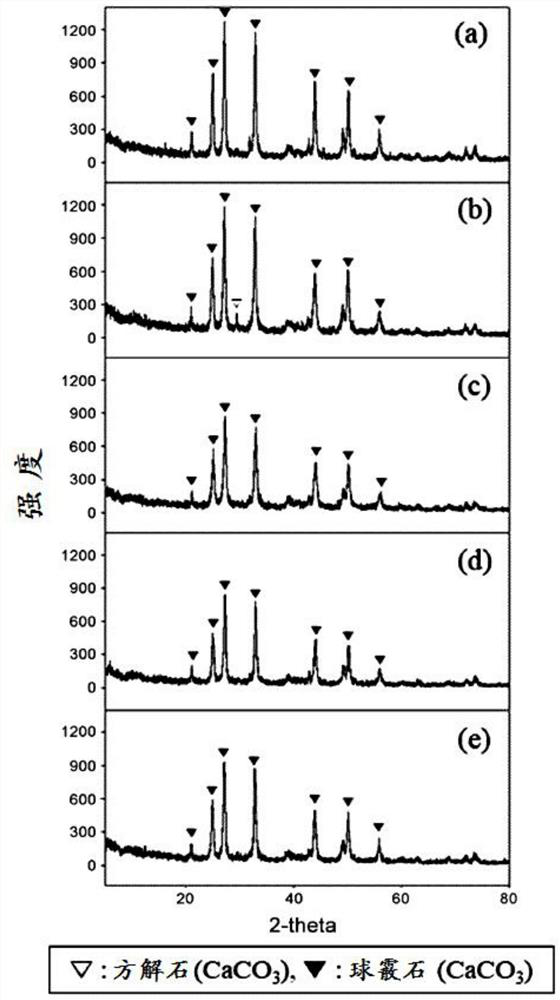

[0086] Seawater or desalinated concentrated water is used as a solvent for the indirect carbonation reaction, and cement kiln dust (CKD) or paper sludge incineration ash (PSA) as an industrial by-product is used as a raw material for the indirect carbonation reaction. In addition, calcium oxide ( CaO) and calcium hydroxide (Ca(OH) 2 ) As the raw material of the indirect carbonation reaction, a calcium eluate was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com