Knitted fabric printing and dyeing pretreatment solution, preparation method thereof and knitted fabric dyeing process

A pretreatment solution and knitted fabric technology, applied in the field of knitted fabric dyeing, can solve the problems of reducing the amount of positive charges on the surface of knitted fabrics, affecting the coloring effect of knitted fabrics, etc., and achieve the effects of increased dyeing rate, low cost, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

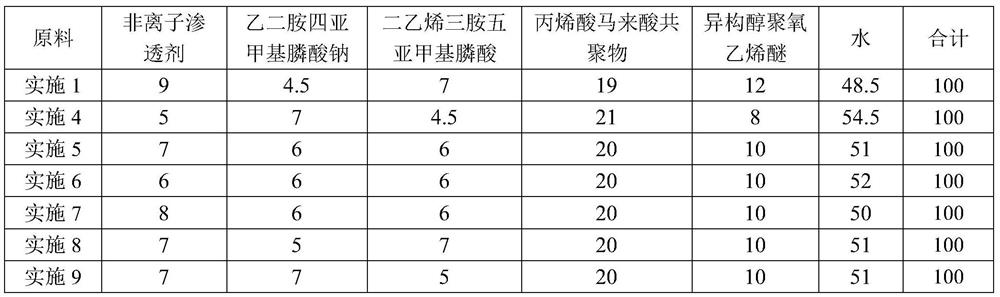

[0051] Preparation Example of Compound Fiber Positive Charge Protector

[0052] The composite fiber positive charge protector is prepared by the following method: adding sodium ethylenediamine tetramethylene phosphonate and diethylene triamine pentamethylene phosphonic acid to water, then adding non-ionic penetrant, methyl maleate acrylate Copolymer and isomeric alcohol polyoxyethylene ether are uniformly mixed to obtain a composite fiber positive charge protector.

Embodiment 1

[0054] A knitted fabric printing and dyeing pretreatment solution. The raw materials of the pretreatment solution include water and a pretreatment agent. The water is a solvent and the pretreatment agent is a solute. The raw material ratio of the pretreatment agent is shown in Table 1 and Table 2.

[0055] A knitted fabric printing and dyeing pretreatment solution is prepared by the following method: add 30% hydrogen peroxide, sodium hydroxide, low-temperature hydrogen peroxide activator, and compound fiber positive charge protector to water, and stir evenly to obtain the pretreatment solution.

Embodiment 2-3

[0057] A kind of knitted fabric printing and dyeing pretreatment liquid, the raw material ratio of compound fiber positive charge protecting agent in embodiment 2-3 and embodiment 1 is the same,

[0058] The difference between embodiment 2-3 and embodiment 1 is that the raw material ratio of the pretreatment agent is different, and the raw material ratio of the composite fiber positive charge protecting agent in the pretreatment agent is the same, and the raw material ratio of the pretreatment agent See Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com