Ceramic membrane denitration and dioxin removal catalyst taking sludge and steel slag as raw materials and preparation method thereof

A catalyst and ceramic membrane technology, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem that particulate matter easily blocks catalyst pores, hinders the development and application of simultaneous denitration and dedioxin catalysts, etc. Achieve excellent redox performance, excellent oxygen storage and release performance, and efficient catalytic removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

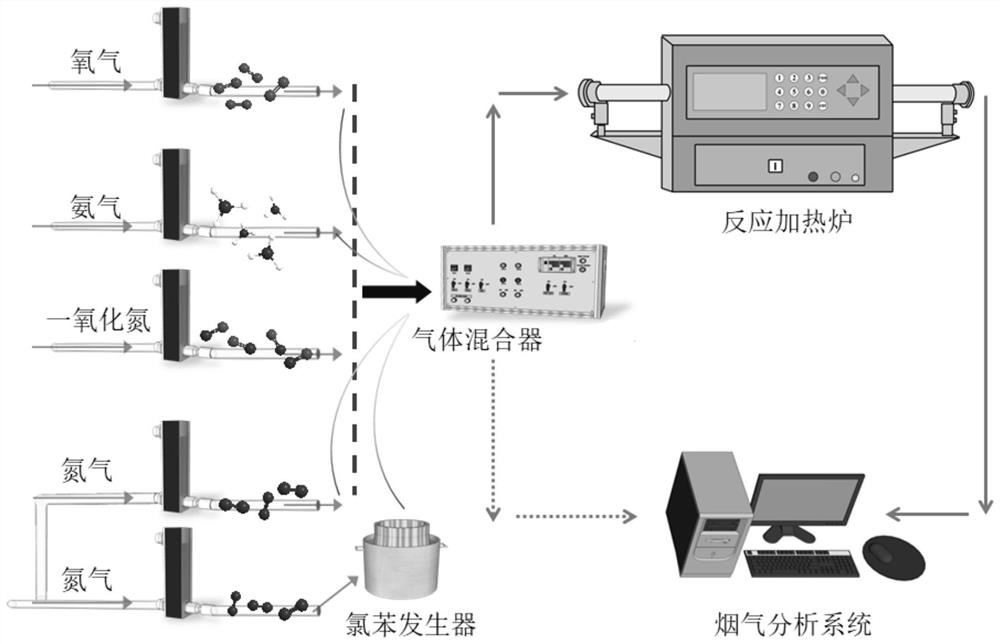

Image

Examples

Embodiment 1

[0032] (1) Raw material crushing

[0033] The steel slag and the metatitanic acid powder are respectively pulverized by a ball mill, passed through a 100-mesh standard sieve and homogenized for later use;

[0034] (2) Ingredients and granulation

[0035] Weigh 20g of steel slag powder and 50g of metatitanic acid powder and stir evenly, then weigh 20g of domestic sludge and 10g of polyvinyl alcohol solution and mix with the above powder for grinding and granulation;

[0036] (3) Molding and calcination

[0037] Weigh 10 g of the granulated mud and add it to the mold, pressurize to 4 MPa, take out the sample after holding the pressure for 2 minutes, and repeat the molding of the green body 10 times to obtain 10 ceramic membrane green bodies with a diameter of 25 mm. Placed in a muffle furnace and kept at 1000°C for 4 hours for calcination to obtain a ceramic membrane carrier;

[0038] (4) Preparation of active component and cocatalyst precursor composite solution

[0039] We...

Embodiment 2

[0045] (1) Raw material crushing

[0046] The steel slag and the metatitanic acid powder are respectively pulverized by a ball mill, passed through a 100-mesh standard sieve and homogenized for later use;

[0047] (2) Ingredients and granulation

[0048] Weigh 10g of steel slag powder and 60g of metatitanic acid powder and stir evenly, then weigh 20g of domestic sludge and 10g of polyvinyl alcohol solution and mix with the above powder for grinding and granulation;

[0049] (3) Molding and calcination

[0050] Weigh 10 g of the granulated mud and add it to the mold, pressurize to 6 MPa, take out the sample after holding the pressure for 2 minutes, and repeat the green body molding 10 times to obtain 10 ceramic membrane green bodies with a diameter of 25 mm. Placed in a muffle furnace and kept at 1200°C for 4 hours for calcination to obtain a ceramic membrane carrier;

[0051] (4) Preparation of active component and co-catalyst precursor composite solution

[0052] Weigh 24...

Embodiment 3

[0058] (1) Raw material crushing

[0059] The steel slag and the metatitanic acid powder are respectively pulverized by a ball mill, passed through a 100-mesh standard sieve and homogenized for later use;

[0060] (2) Ingredients and granulation

[0061] Weigh 20g of steel slag powder and 60g of metatitanic acid powder and stir evenly, then weigh 10g of domestic sludge and 10g of polyvinyl alcohol solution and mix with the above powder for grinding and granulation;

[0062] (3) Molding and calcination

[0063] Weigh 10 g of the granulated mud and add it to the mold, pressurize to 6 MPa, take out the sample after holding the pressure for 2 minutes, and repeat the green body molding 10 times to obtain 10 ceramic membrane green bodies with a diameter of 25 mm. Placed in a muffle furnace and kept at 1000°C for 4 hours for calcination to obtain a ceramic membrane carrier;

[0064] (4) Preparation of active component and co-catalyst precursor composite solution

[0065] Weigh 9....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com