Soluble non-denatured II-type collagen and preparation method thereof

A collagen, non-denaturing technology, applied in chemical instruments and methods, animal/human proteins, connective tissue peptides, etc., can solve the problems of long extraction time, unfavorable scale production, and low product purity, and achieve a simple and easy preparation method , easy large-scale production, good product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

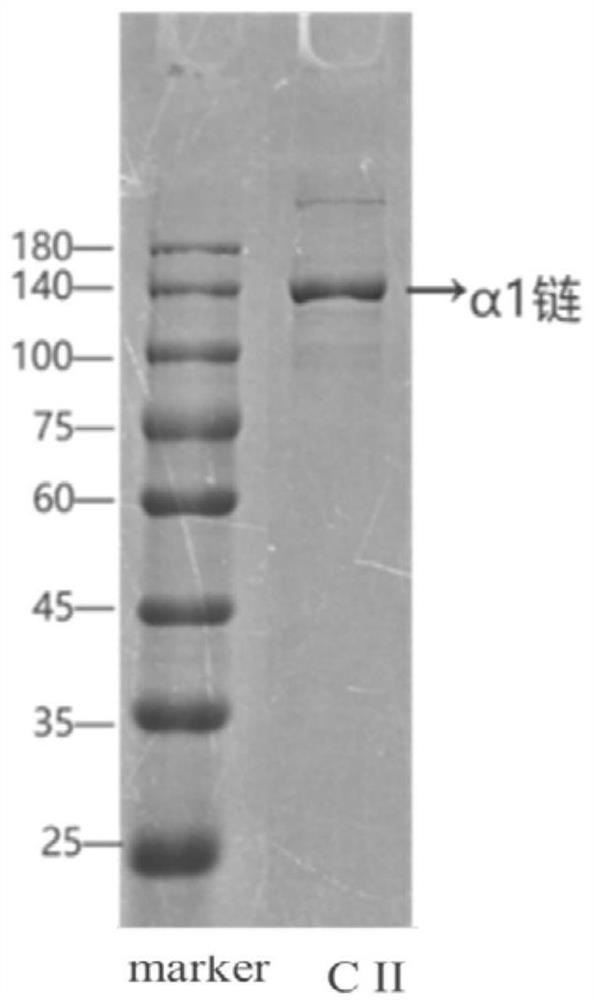

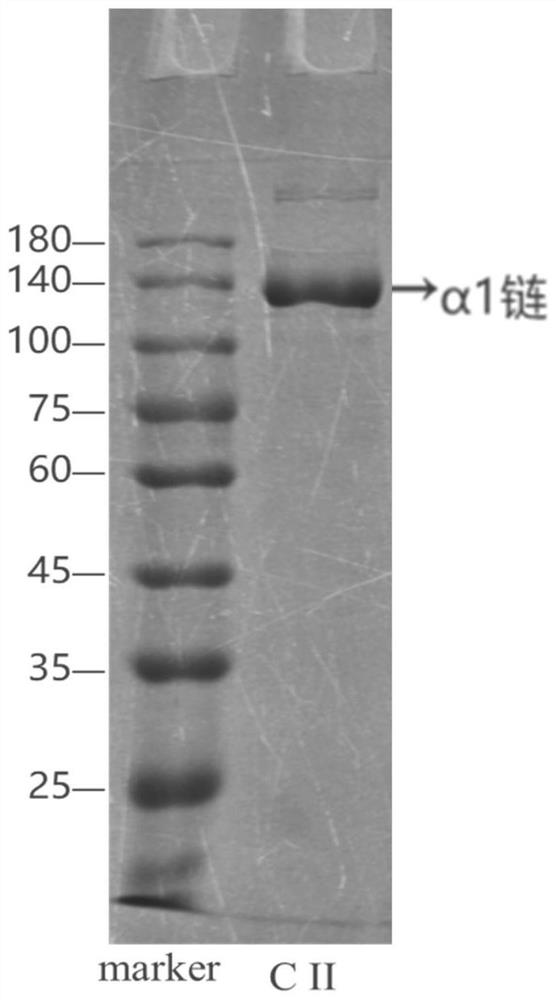

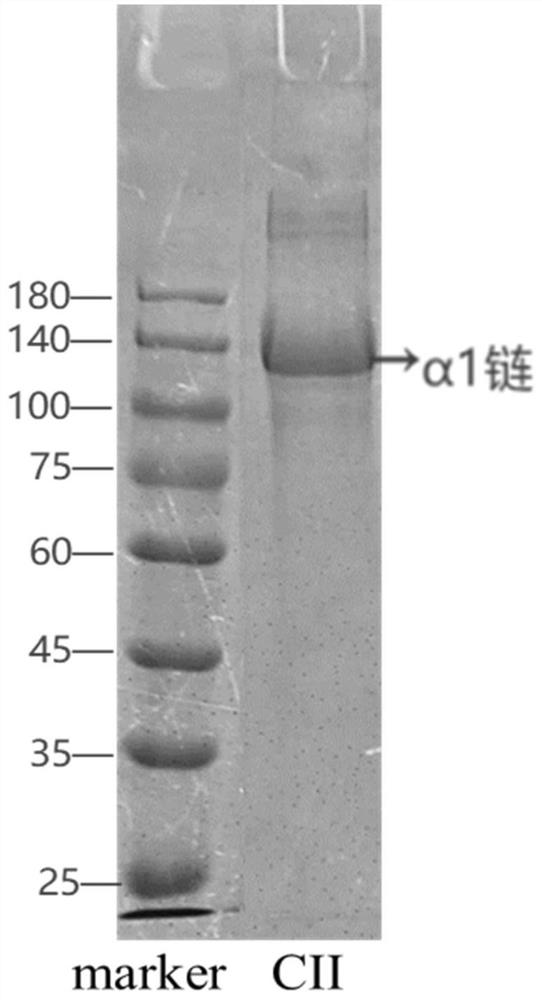

Image

Examples

Embodiment 1

[0047] 1. Thaw 50kg of chicken breast cartilage and drain the water, add 200L of pure water, and homogenize in a colloid mill;

[0048] 2. Take the homogenate, add 7.5kg of NaCl, 9.5kg of KCl and 250g of NaOH while stirring, mix evenly, and ultrasonicate for 35min at 30kHz and 300W;

[0049] 3. Take the precipitate by centrifugation, add 150L 0.001mol / L hydrochloric acid solution, and carry out acid swelling treatment. The acid swelling treatment time is 60min, and adjust the pH to 3.0 after stabilization;

[0050] 4. Add 0.5kgNaCl, 0.5kgCaCl 2 , 50g of pepsin and 50g of papain, hydrolyzed for 14 hours at 15°C, after the hydrolysis, adjust the pH to 8.0 to inactivate the enzyme, centrifuge to get the supernatant;

[0051] 5. Adjust the pH of the supernatant to 7.0, add 44kgNaCl while stirring, salt out for 2 hours, and centrifuge to collect the precipitate;

[0052] 6. Suspend the precipitate in pure water, wash, centrifuge to get the precipitate, repeat 4 times;

[0053] 7...

Embodiment 2

[0056] 1. Thaw 60kg of chicken breast cartilage and drain the water, add 250L of pure water, and homogenize in a colloid mill;

[0057] 2. Take the homogenate, add 20kg of NaCl and 1000g of NaOH while stirring, and ultrasonicate for 10min at 40kHz, 300W;

[0058] 3. Take the precipitate by centrifugation, add 300L 0.1mol / L hydrochloric acid solution, and carry out acid swelling treatment. The time of acid swelling treatment is 15 minutes, and adjust the pH to 1.0 after stabilization;

[0059] 4. Add 3kgNaCl, 0.3gMgCl 2 , 1200g of pepsin, hydrolyzed for 6 h, the temperature of enzymolysis is 4°C, after the end of the enzymolysis, adjust the pH to 7.5 to inactivate the enzyme, centrifuge to get the supernatant;

[0060] 5. Adjust the pH of the supernatant to 5.0, add 30kgNaCl while stirring, salt out for 20 hours, and centrifuge to collect the precipitate;

[0061] 6. Suspend the precipitate in pure water, wash and centrifuge to get the precipitate, repeat 5 times;

[0062] 7...

Embodiment 3

[0065] 1. Thaw 50kg of chicken breast cartilage and drain the water, add 300L of pure water, and homogenize in a colloid mill;

[0066] 2. Take the homogenate, add 30kg of KCl and 1.8kg of NaOH while stirring, and ultrasonicate for 60min at 20kHz and 300W;

[0067] 3. Take the precipitate by centrifugation, add 200L 0.01mol / L hydrochloric acid solution, and carry out acid swelling treatment. The time of acid swelling treatment is 100min, and adjust the pH to 5.0 after stabilization;

[0068] 4. Add 250kgNaCl, 250g catechin, 100g papain and 100g bromelain, enzymatically hydrolyze for 2 hours, and the enzymolysis temperature is 35°C. After the enzymolysis, adjust the pH to 7.8 to inactivate the enzyme, and centrifuge to get the supernatant;

[0069] 5. Adjust the pH of the supernatant to 2.0, add 1.2kgNaCl while stirring, salt out for 20 hours, and centrifuge to collect the precipitate;

[0070] 6. Suspend the precipitate in pure water, wash, centrifuge to get the precipitate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com