Anti-haze antibacterial filtering material and preparation method thereof

A filter material and filter layer technology, applied in the direction of filtration separation, separation method, dispersed particle filtration, etc., can solve the problems of filtration efficiency and air resistance that cannot be reused, achieve safety and comfort, and reduce ventilation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

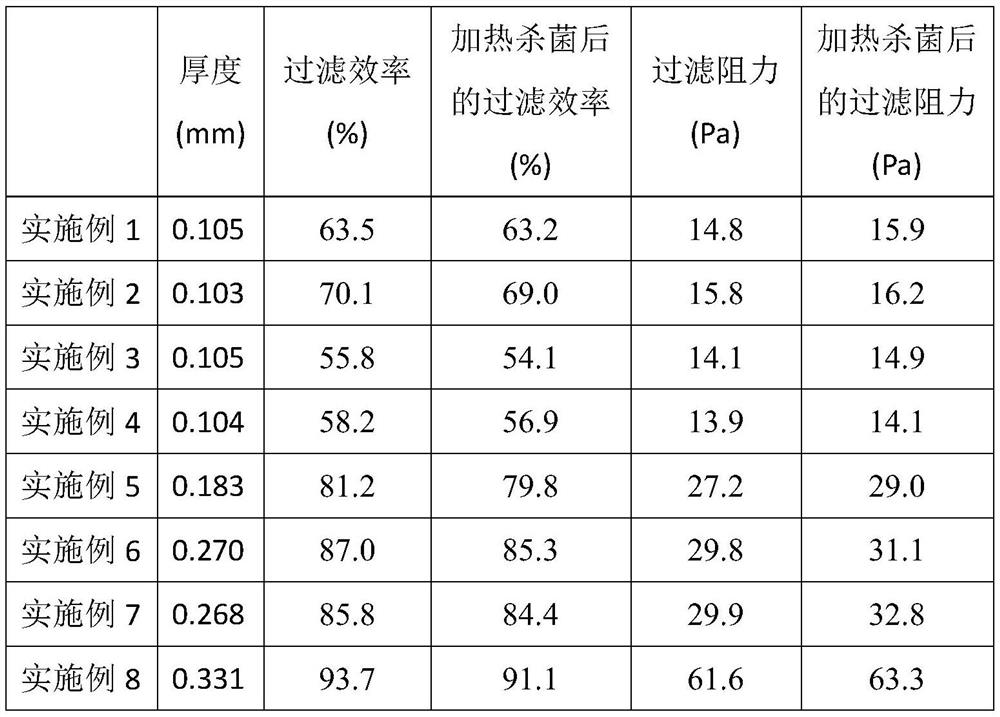

Examples

Embodiment 1

[0033] The preparation raw material of anti-haze antibacterial filtering material described in the present embodiment comprises (in parts by weight): 100 parts (60wt%) of deproteinized natural rubber latex, 4 parts of p-cresol and dicyclopentadiene butyl compound, preservative 0.15 parts, thickener 1.5 parts, emulsifier 0.1 parts, emollient 1.5 parts, functional particles 8.0 parts and purified water 60 parts.

[0034] Described antiseptic is methylparaben and ethylparaben of mass ratio 1:1;

[0035] Described thickening agent is the carbomer of mass ratio 2:1:1, cyclodextrin and chitosan;

[0036] The emulsifier is Tween-60 and Span-40 with a mass ratio of 1:1;

[0037] The emollient is glycerol and D-panthenol with a mass ratio of 4:1;

[0038] The functional particles are activated carbon, nano silicon dioxide and nano titanium dioxide with a mass ratio of 4:2:1.

[0039] The preparation method of anti-haze antibacterial filter material described in the present embodimen...

Embodiment 2

[0047] The preparation raw material of anti-haze antibacterial filter material described in the present embodiment comprises (in parts by weight): 100 parts (60wt%) of deproteinized natural rubber latex, 0.2 part of antiseptic, 1.8 parts of thickener, 0.15 part of emulsifier, 2 parts of antioxidant, 1.0 part of emollient, 7.5 parts of functional particles and 60 parts of purified water.

[0048] Described preservative is methylparaben and ammonium naphthenate of mass ratio 1:1;

[0049] The antioxidant is cresol and dicyclopentadiene butyl compound and KY405 with a mass ratio of 2:1;

[0050] Described thickening agent is the konjac polysaccharide, cyclodextrin and carboxylated chitosan of mass ratio 2:1:1;

[0051] Described emulsifying agent is the polyoxyethylene ether and polyglycerol glycidyl ether of mass ratio 1:1;

[0052] Described emollient is the water-soluble petroleum resin and laurocaprazine of mass ratio 2:1;

[0053] The functional particles are activated ca...

Embodiment 3

[0062] The preparation raw material of anti-haze antibacterial filter material described in the present embodiment comprises (in parts by weight): 100 parts (60wt%) of deproteinized natural rubber latex, 0.3 part of antiseptic, 1.0 part of thickener, 0.2 part of emulsifier, 4 parts of antioxidant, 0.8 part of emollient, 8.5 parts of functional particles and 60 parts of purified water.

[0063] Described preservative is ethylparaben and sodium benzoate of mass ratio 2:1;

[0064] The antioxidant is cresol and dicyclopentadiene butyl compound and CPL (hindered phenol) with a mass ratio of 2:1;

[0065] The thickener is carbomer and bacterial cellulose with a mass ratio of 1:1;

[0066] Described emulsifier is betaine and polyvinylpyrrolidone of mass ratio 1:1;

[0067] Described emollient is the water-soluble silicone oil and the water-soluble petroleum resin of mass ratio 2:1;

[0068] The functional particles are nano-calcium carbonate and sepiolite with a mass ratio of 1:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com