Liquid anode and method for enriching and separating anions in water body

An anode and liquid technology, applied in the field of water treatment, can solve the problems such as the difficulty of effectively removing anions, achieve the effect of accelerating the exchange current density, simple preparation, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

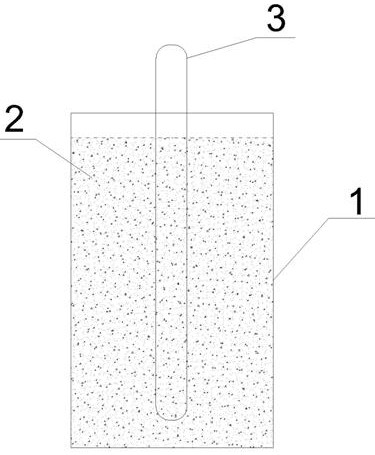

[0022] Embodiment 1: liquid anode structure such as figure 1 As shown, including hydrophilic PVC solid-carrying film 1, hydrophobic dianionic ionic liquid 2, and Fe electrode 3; the hydrophobic liquid is filled in a bag made of hydrophilic solid-carrying film, and then the conductive electrode is placed in it Prepare a liquid anode;

[0023] The preparation method of hydrophilic PVC immobilized film is as follows: dissolve 3.6g of polyvinyl chloride in 38.6g of dimethylacetamide solution, stir until it is completely dissolved, add 0.41g of vinyl acetate, and keep stirring, Add 1.5g of nano-alumina powder during the stirring process, then immediately add 0.3g of dispersant sodium hexametaphosphate, and finally add 2.0g of pore-forming agent polyvinylpyrrolidone, stir evenly for 24 hours, seal and stand for defoaming, and then cast the film Cast the solution on a clean glass plate, scrape it until it forms a film, volatilize for 60 seconds, put it into the 25% ethanol coagulati...

Embodiment 2

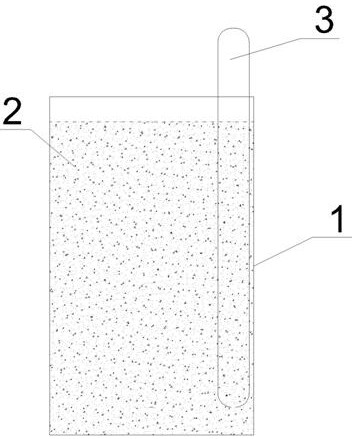

[0026] Embodiment 2: liquid anode structure such as figure 2 As shown, it includes hydrophilic PVA solid-carrying film 1, hydrophobic conductive liquid 2, and Cu electrode 3; the hydrophobic liquid is filled in a bag made of hydrophilic solid-carrying film, and then the conductive electrode is placed in it to obtain a liquid state anode;

[0027] The preparation method of the hydrophilic PVA immobilized membrane is as follows: Weigh 6g of PVA into 54mL of distilled water, and heat to completely dissolve the PVA in distilled water, then add 4.20g of glacial acetic acid to the solution, stir evenly to prepare a membrane-making solution, Stand by after soaking off. Wet the clean polyester filter cloth with water and lay it flat on the glass plate, flat and free of air bubbles, pour the film-making solution on the filter cloth, scrape it into a liquid film with a uniform thickness with a glass rod, put the prepared film on the Dry in an oven at 60°C for 3 hours, then air-dry na...

Embodiment 3

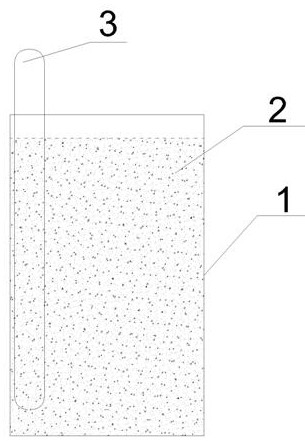

[0030] Embodiment 3: liquid anode structure such as image 3 As shown, it includes hydrophilic PVDF solid-carrying film 1, hydrophobic conductive liquid 2, and graphite electrode 3; the hydrophobic liquid is filled in a bag made of hydrophilic solid-carrying film, and then the conductive electrode is placed in it to obtain a liquid state anode;

[0031] The hydrophilic PVDF immobilized membrane is prepared as follows: PVDF is selected as material, N,N-dimethylacetamide (DMAc) is used as solvent, polyvinylpyrrolidone (PVP) and polyethylene glycol (PEG) are used as additives, among which PVDF and PVP 18% and 14% respectively, and the molecular weight of PEG is 200. PVDF, PVP and PEG are mixed and dissolved in DMAc, and after static defoaming and filtration, a casting solution is formed, heated to ripening, and vacuum degassed in a vacuum box again. Then use a frame-type applicator to form a film on flat glass, put it in a coagulation bath, and soak it in alcohol and distilled w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com