Aluminum-air battery cathode catalyst and preparation method thereof

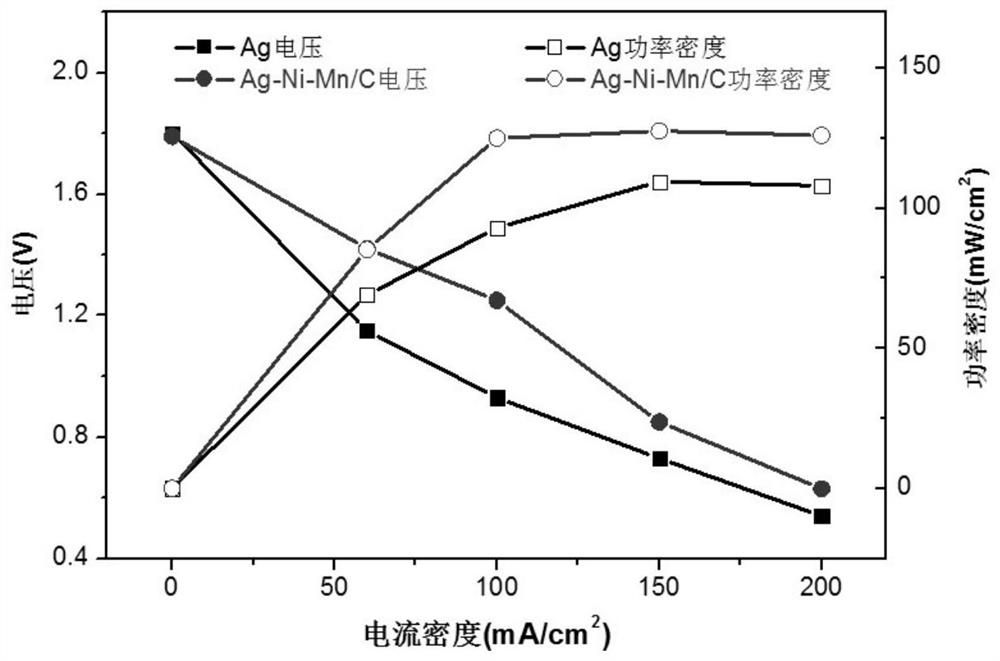

A cathode catalyst, aluminum-air battery technology, which is applied in battery electrodes, fuel cell-type half-cells and primary-cell-type half-cells, circuits, etc. Battery commercialization process and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1, take 1g of silver nitrate and 1.5g of nickel nitrate, add them to 20ml of deionized water to dissolve, then add an appropriate amount of urea to adjust the pH of the solution, then slowly add an appropriate amount of hydrogen peroxide as a reducing agent, and an appropriate amount of polyethylene glycol as a surfactant; 50 ℃ water bath for 30 minutes to obtain the reaction solution;

[0033] Step 2, adding 5 g of manganese nitrate and 5 g of activated carbon to the reaction solution obtained in step 1, and ultrasonically stirring for 1 h to obtain a catalyst precursor;

[0034] Step 3: Put the catalyst precursor in an oven and dry it at 80°C for 120 minutes, transfer the dried solid to a ball mill for ball milling for 60 minutes, and sieve to obtain the precursor powder;

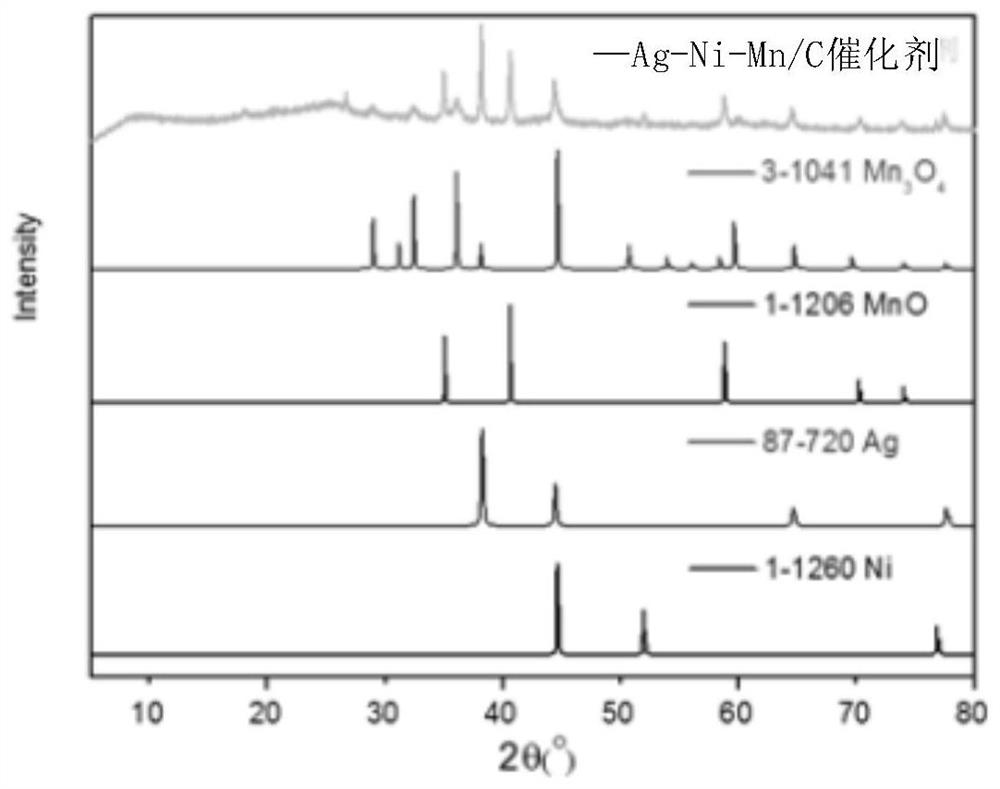

[0035] Step 4: Put the precursor powder into a crucible, calcinate in a muffle furnace at 200° C. for 180 min, and cool naturally to obtain an Ag-Ni double-doped carbon-supported manganese cat...

Embodiment 2

[0037] Step 1: Take 1.5g of silver acetate and 1g of nickel acetate and dissolve them in 20ml of deionized water, then add an appropriate amount of ammonium carbonate to adjust the pH of the solution, then slowly add an appropriate amount of hydrazine hydrate as a reducing agent, and an appropriate amount of sodium dodecylbenzenesulfonate As a surfactant; react in a water bath at 90°C for 50 minutes to obtain a reaction solution;

[0038] Step 2, adding 10 g of manganese acetate and 5 g of acetylene black to the reaction solution obtained in step 1, and ultrasonically stirring for 40 min to obtain a catalyst precursor;

[0039] Step 3: put the catalyst precursor in an oven and dry it at 120°C for 300 minutes, transfer the dried solid to a ball mill for ball milling for 50 minutes, and sieve to obtain the precursor powder;

[0040] Step 4: Put the precursor powder into a crucible, calcinate in a muffle furnace at 400° C. for 60 minutes, and cool naturally to obtain an Ag-Ni dou...

Embodiment 3

[0042] Step 1: Take 1.5g of silver acetate and 1g of nickel nitrate and dissolve them in 10ml of absolute ethanol, then add an appropriate amount of ammonia water to adjust the pH of the solution, then slowly add an appropriate amount of hydrogen peroxide as a reducing agent, and an appropriate amount of hexadecyl trimethyl bromide Ammonium is used as a surfactant; react in a water bath at 60°C for 50 minutes to obtain a reaction solution;

[0043] Step 2, adding 10 g of manganese acetate and 5 g of carbon nanotubes to the reaction solution obtained in step 1, and ultrasonically stirring for 30 min to obtain a catalyst precursor;

[0044] Step 3: put the catalyst precursor in an oven and dry it at 60°C for 500 minutes, transfer the dried solid to a ball mill for ball milling for 50 minutes, and sieve to obtain the precursor powder;

[0045] Step 4: Put the precursor powder into a crucible, calcinate in a muffle furnace at 500° C. for 360 minutes, and cool naturally to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com