Preparation method of nanowire/silicon-aluminum aerogel composite material

A technology of composite materials and nanowires, applied in the field of preparation of inorganic nanoporous materials, can solve the problems of easy structure collapse, complex process, and limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take a certain quality of surfactant and dissolve it in a certain volume of deionized water, the mass fraction is 1.8%, add 24ml0.04M cetyltrimethylammonium bromide (CTAB); after the surfactant is completely dissolved, Add 8ml of hydrochloric acid, and stir the mixed solution at 27°C; measure 0.85ml of tetraethyl orthosilicate as a silicon source and add it to the mixed solution, stir well and let it stand at room temperature for about 10h; filter the obtained gel with suction , dried, in a muffle furnace at a heating rate of 2K / min to 200 °C, and then at a rate of 1 K / min to 550 °C to remove residual surfactants to obtain SiO 2 Nanowire white powder.

[0026] Weigh 6.5g of aluminum chloride hexahydrate, add 10ml of absolute ethanol and 10ml of deionized water at a ratio of 1:1, stir magnetically until the aluminum chloride is completely dissolved; add ethyl orthosilicate at a ratio of 6:1 of aluminum to silicon , Stir for 24h to complete the hydrolysis. 0.1g prepared...

Embodiment 2

[0029] The operating method is the same as in Example 1, except that the SiO added in the silica-alumina sol 2 The nanowire mass is 0.2g.

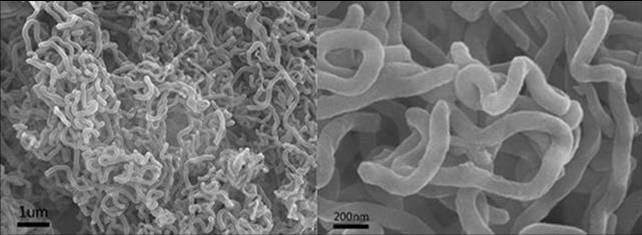

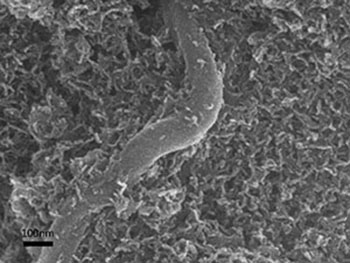

[0030] Depend on figure 2 It can be seen that SiO 2 The nanowire nanowires are evenly distributed in the matrix, and the airgel particles are tightly bound to the surface of the nanowires, indicating that the SiO 2 Nanowires are highly compatible with airgel particles, and there is no problem of surface tension.

Embodiment 3

[0032] The operating method is the same as in Example 1, except that the SiO added in the silica-alumina sol 2 The nanowire mass is 0.3g.

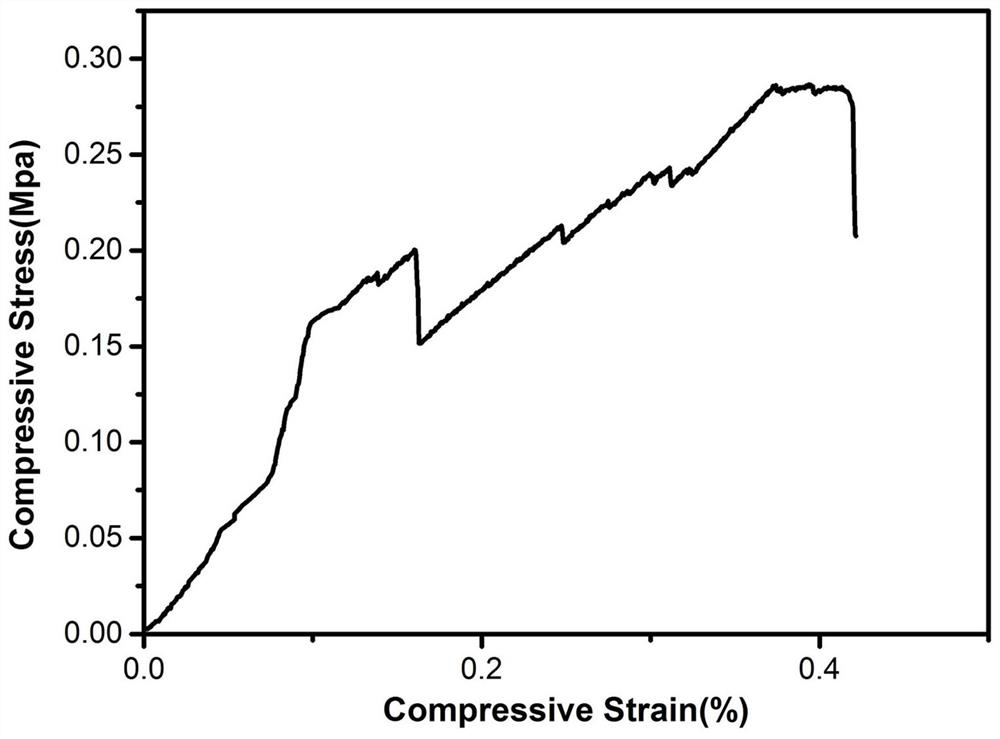

[0033] Depend on image 3 It can be seen that when the strain is 40%, the composite material reaches the highest compressive stress of 0.28 MPa, and there is a fairly long deformation zone until the material fails completely (60%), indicating that SiO 2 The addition of nanowires not only enhances the fracture strength of the airgel composite, but also significantly reduces the slope of the elastic deformation zone, that is, the toughness of the material is enhanced and the brittleness is reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com