Green and environment-friendly chemical mechanical polishing method for cadmium zinc telluride wafer

A technology of cadmium zinc telluride wafer and chemical machinery, which can be applied to polishing compositions containing abrasives, grinding machine tools, electrical components, etc., and can solve problems such as affecting the polishing effect of CZT wafers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

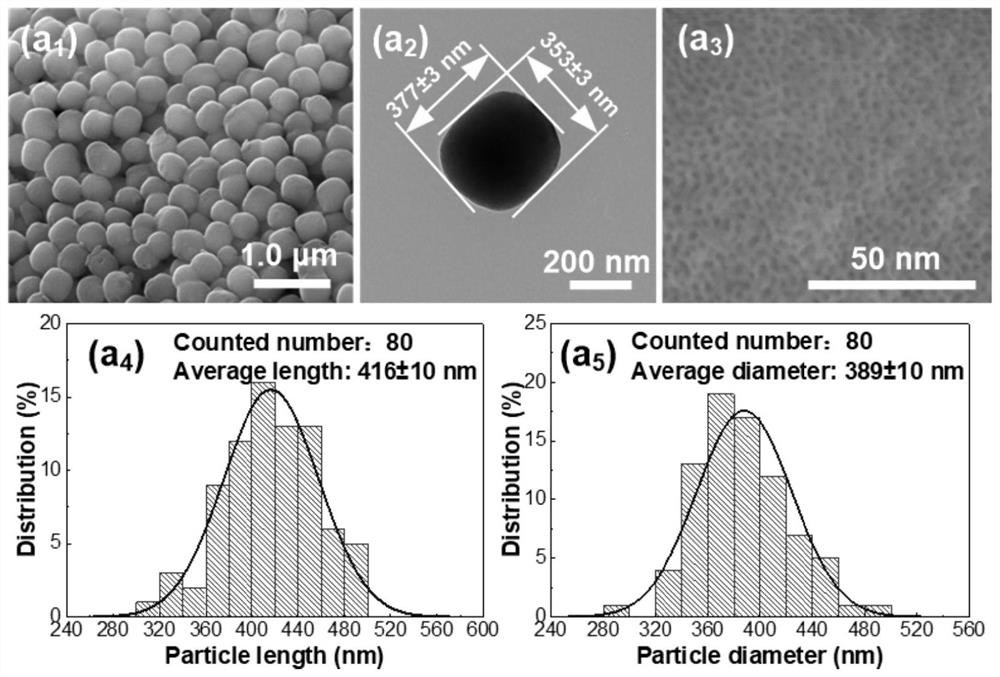

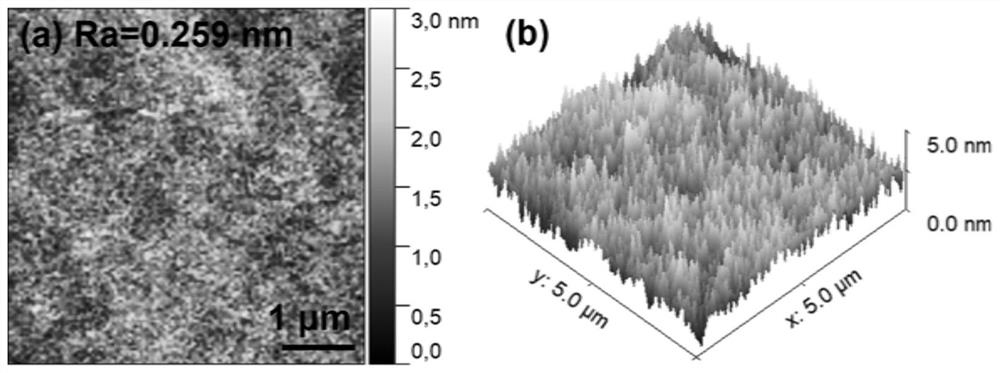

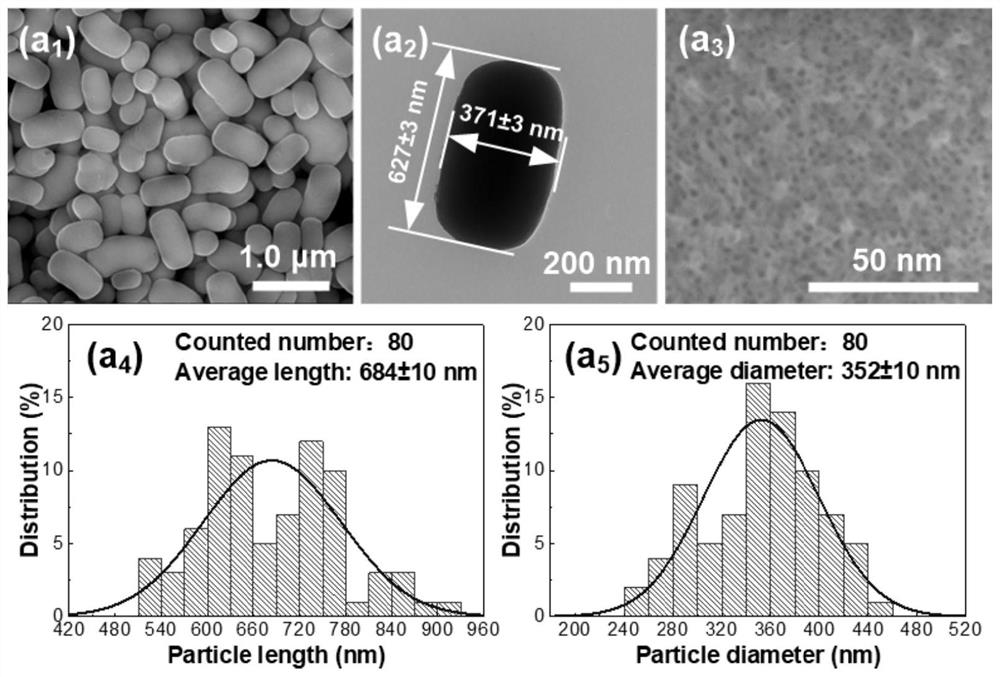

Image

Examples

Embodiment

[0028] Firstly, the CZT samples were ground. Cut a CZT wafer with a thickness of 1.2-1.5mm into about 1×1cm 2 Take 3 cut CZT samples and glue them on the same circumference of the aluminum alloy loading plate evenly spaced. Bonded silicon carbide sandpaper with an abrasive grain size of #4000 was pasted and fixed on a cast iron grinding disc. During grinding, the grinding pressure is 30kPa, the rotational speed of the grinding disc and the loading disc are both 50rpm, the grinding liquid is deionized water, the flow rate of deionized water is 10mL / min, and the grinding time is 60s. After the CZT sample was ground, it was rinsed with deionized water and ethanol for 18 min respectively, and dried with compressed air. In the grinding stage, fixed abrasives are used for grinding. Compared with free abrasives, the surface oxide layer and damaged layer caused by ingot cutting can be quickly and efficiently realized, the surface is flattened, and unnecessary surface defects caused ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com